Diode device and manufacturing process thereof

A manufacturing process and diode technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of low reverse withstand voltage, and achieve the effect of low on-voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

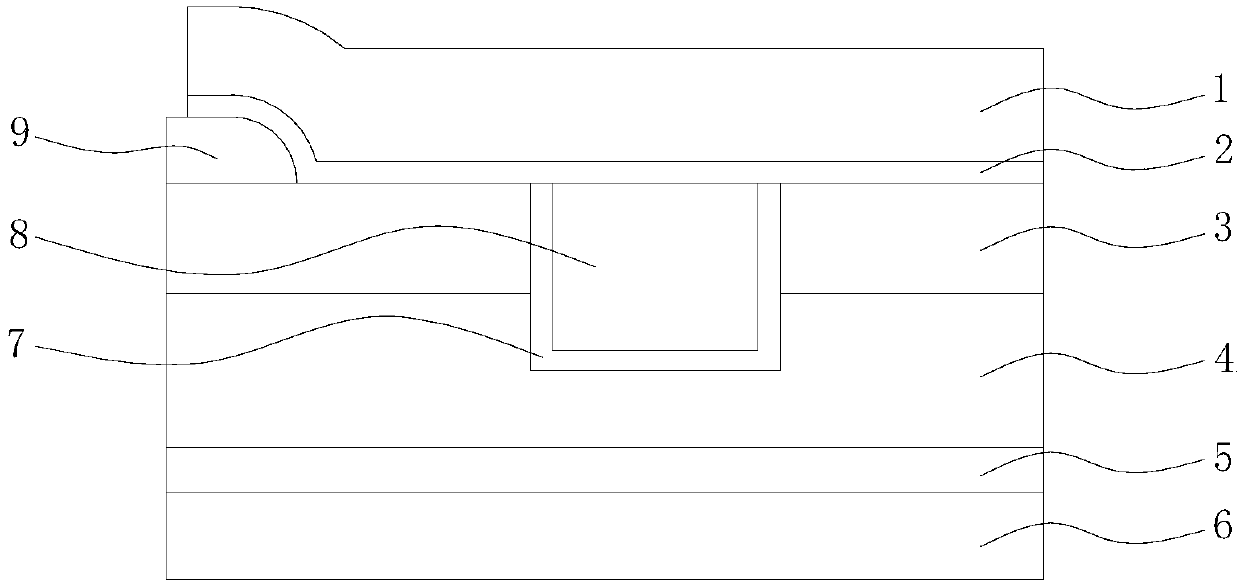

[0054] Furthermore, please also refer to figure 1 and Figure 7-10 , as a specific embodiment of the diode device provided by the present invention, it also includes a dielectric oxide layer 9 located at one end of the P-type doped region 3, and the dielectric oxide layer 9 is arranged between the barrier layer 2 and the P-type doped region 3 space, and a part of the dielectric oxide layer 9 is exposed to the air. The arrangement of the dielectric oxide layer 9 improves the reverse withstand voltage capability of the diode device, and can prevent external foreign matter from invading into the diode device to protect the diode device.

[0055] Please also refer to Figure 1-10 , the manufacturing process of the diode device provided by the present invention will now be described. A manufacturing process for a diode device, comprising the following steps:

[0056] S1. Prepare N-type lightly doped region 4;

[0057] S2, forming a P-type doped region 3 on the N-type lightly ...

specific Embodiment approach

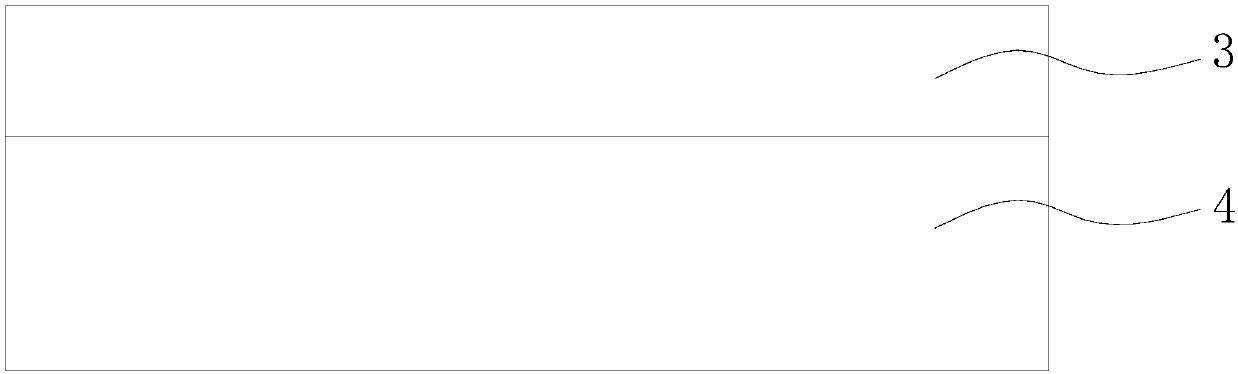

[0070] Further, see figure 2 , as a specific implementation of the manufacturing process of the diode device provided by the present invention, step S2 includes:

[0071] The P-type doped region 3 is formed by ion implantation on the wafer, by diffusion on the furnace tube or by vapor phase epitaxy on the N-type lightly doped region 4 .

[0072] Tight integration can be achieved between the P-type doped region 3 and the N-type lightly doped region 4 formed by ion implantation, by diffusion on the furnace tube or by vapor phase epitaxy, so that the electrons in the P-type The movement between the doped region 3 and the N-type lightly doped region 4 is more sufficient.

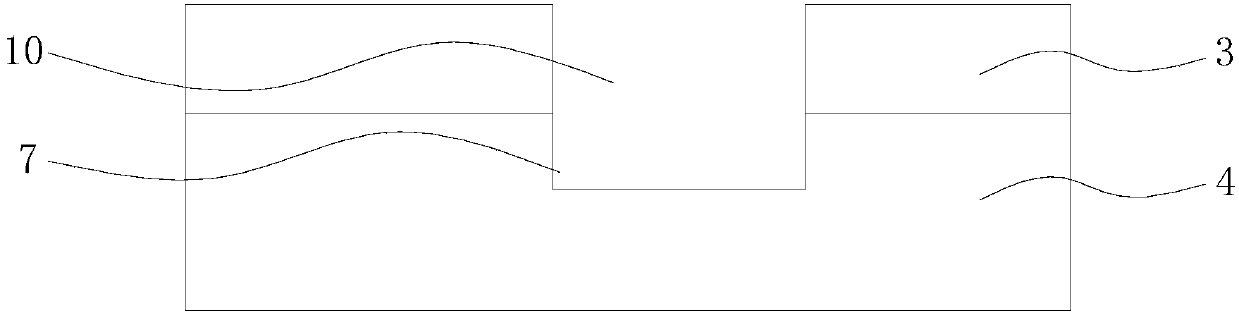

[0073] Specifically, the setting of the concentration of the P-type doped region 3 will enable electrons to accumulate around the oxide layer 7, and the P-type doped region 3 will also be able to form a Schottky contact with the barrier layer 2, thereby improving the efficiency of the diode device. reverse wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com