JBS (Junction Barrier Schottky) diode

A junction barrier Schottky and diode technology, applied in the field of diodes, can solve the problems of large reverse leakage current and low reverse bias voltage of Schottky diodes, and achieve the effect of improving withstand voltage performance and improving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

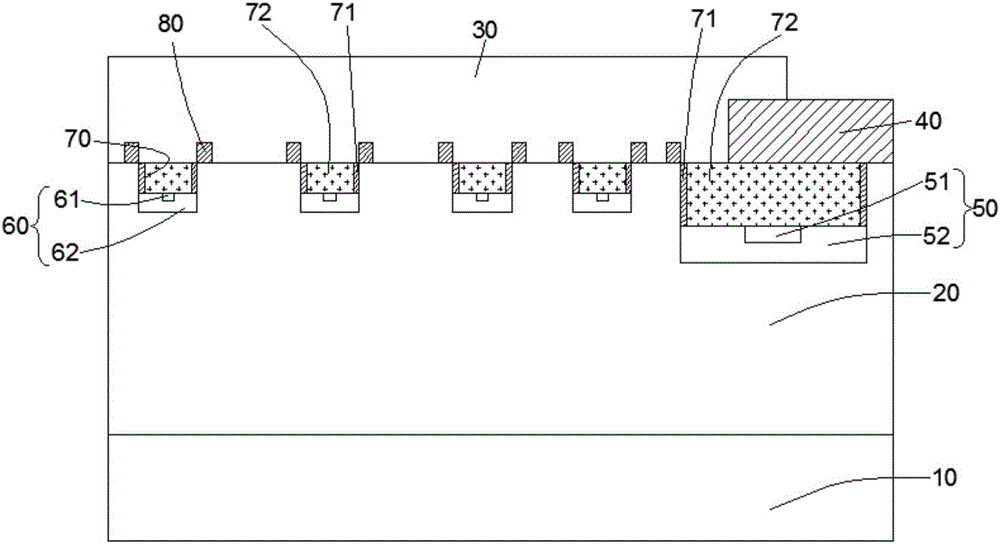

[0025] like figure 1 As shown, a junction barrier Schottky diode includes: a first conductivity type substrate 10, a first conductivity type semiconductor layer 20 formed on the first conductivity type substrate 10, and a first conductivity type semiconductor layer 20 formed on the first conductivity type substrate An anode metal layer 30 on the conductivity type semiconductor layer 20 and forming a Schottky contact with it, an insulating layer 40 formed on the first conductivity type semiconductor layer 20 from the edge of the anode metal layer 30 to the outer side, formed on the insulation layer 30 Layer 40 and the terminal protection area 50 of the second conductivity type under the anode metal layer 30, forming a plurality of second conductivity type semiconductor layers with a certain interval in the upper surface layer of the first conductivity type semiconductor layer 20 inside the terminal protection area 50 The semiconductor region 60, a plurality of trenches 70 with ...

no. 2 example

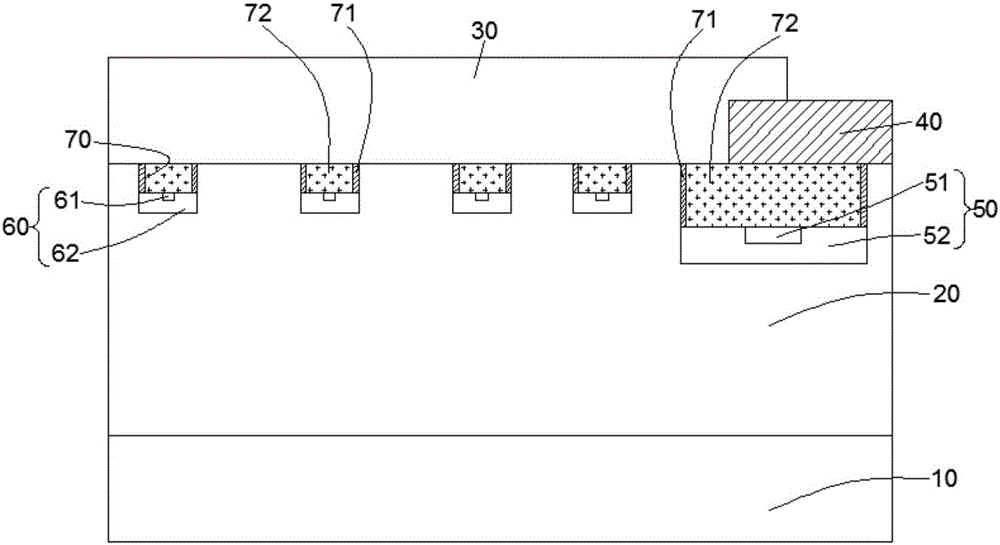

[0033] In this embodiment, compared with the first embodiment, the groove between the first conductivity type semiconductor layer 20 and the anode metal layer 30 and the groove above the second conductivity type semiconductor region 60 outside the notch of the groove 70 above the terminal protection region 50 The insulating dielectric region 80 is formed between the first conductivity type semiconductor layer 20 outside the notch of the trench 70 and the anode metal layer 30 to prevent the contact between the first conductivity type semiconductor layer 20 at the notch of the trench 70 and the anode metal layer 30 from causing tip discharge to increase leakage current.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com