Groove-type MOS Schottky rectifier with deep grooves and T-POLY structure and manufacturing method thereof

A T-POLY, manufacturing method technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as unfavorable advantages, optimize space constraints, etc., to improve reverse voltage withstand performance and increase breakdown voltage , the effect of reducing the forward voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

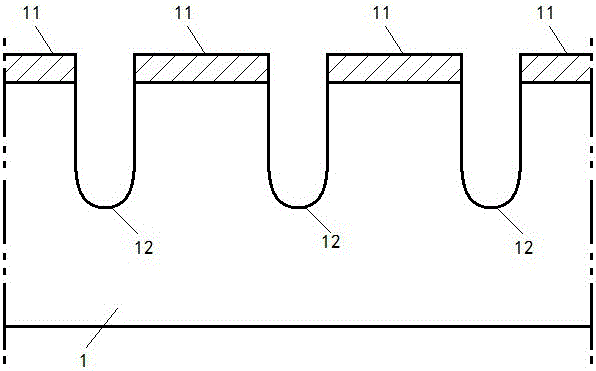

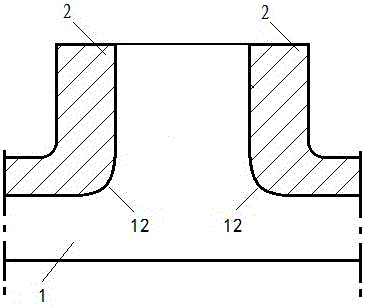

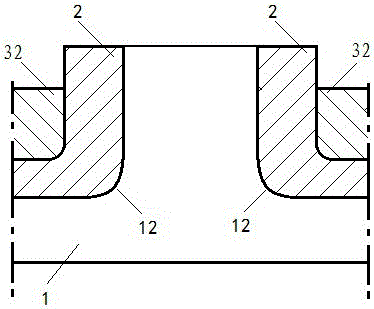

[0029] Such as Figure 8 As shown, the embodiment of the present invention provides a trench-type MOS Schottky rectifier with a deep trench and a T-POLY structure, including an epitaxial layer 1 on which several longitudinal trenches are etched along a lateral interval. The trench 12 is characterized in that the trench 12 extends downward from the upper surface of the epitaxial layer 1, the thickness of the epitaxial layer 1 is D, wherein D is greater than 0, and the depth of the trench 12 is The bottom of each trench 12 and the two inner sidewalls are all provided with an insulating medium 2, and the insulating medium 2 located on the two inner sidewalls is in the shape of a step with a narrow top and a wide bottom; polycrystalline 3 is deposited in each trench 12, so The polycrystal 3 has a T-shaped structure and is closely attached to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com