Schottky diode and manufacturing method thereof

A technology of Schottky diodes and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of not being able to take full account of the problems, and achieve the effects of optimizing electrical parameter characteristics and low forward voltage drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

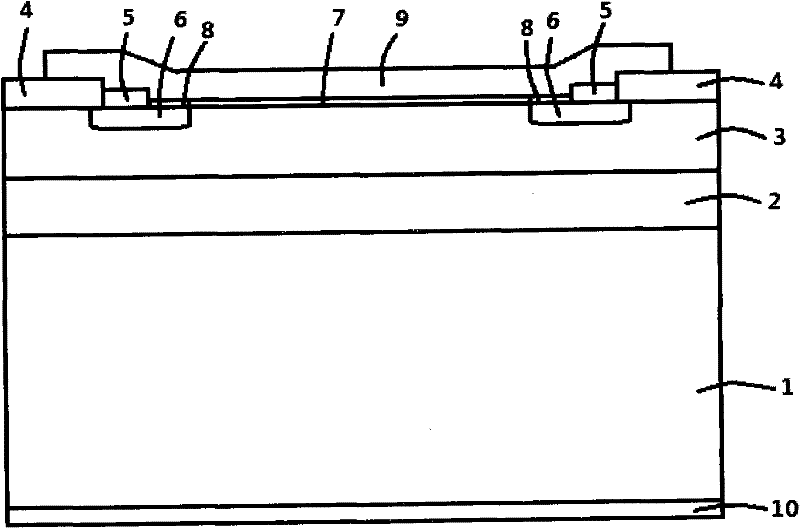

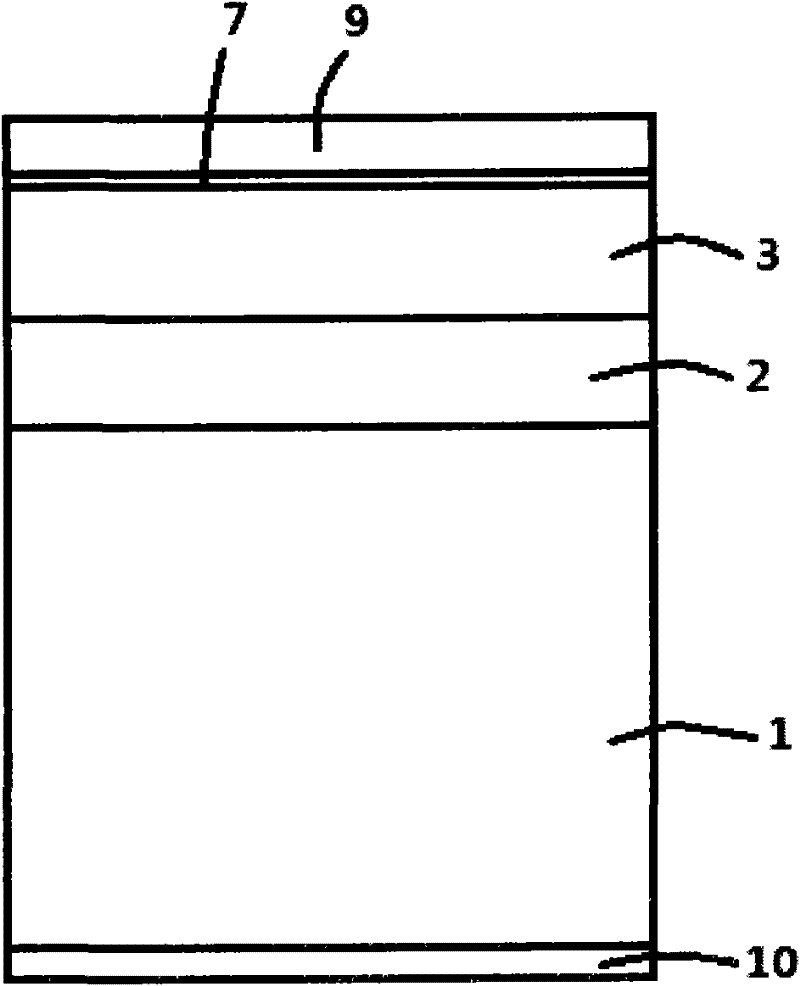

[0050] figure 1 Shows a schematic cross-sectional view of an embodiment of the present invention, combined below figure 1 The semiconductor device of the present invention will be described in detail.

[0051] A Schottky diode includes: a substrate layer 1, which is an N-conduction type silicon semiconductor material, and the cathode of the device is drawn out through a cathode metal layer 10 on the lower surface of the substrate layer; a buffer layer 2, located on the substrate layer 1, is an N-conduction type Silicon semiconductor material, the impurity concentration of this layer of semiconductor material gradually decreases as it moves away from the substrate layer; the drift layer 3, located on the buffer layer 2, is an N-conduction type silicon semiconductor material; the guard ring 6, located in the Schottky barrier layer 7 edge, the guard ring 6 is a P-conduction type silicon semiconductor material, the guard ring 6 is located in the drift layer 3, and the width of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com