Semiconductor device

A semiconductor and depletion layer technology, applied in the structure and manufacturing process of junction barrier Schottky devices, can solve problems affecting device applications, low forward voltage drop switching speed, low reverse voltage, etc., and achieve electrical parameters Effects of characteristic optimization, reduction of reverse leakage current, and improvement of switching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

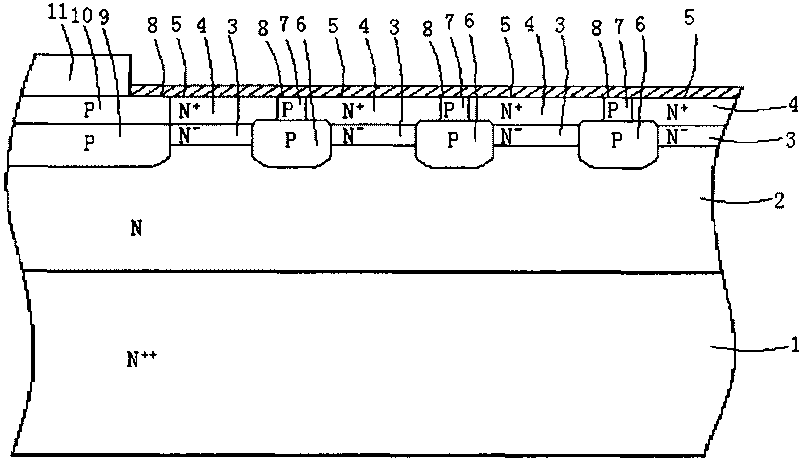

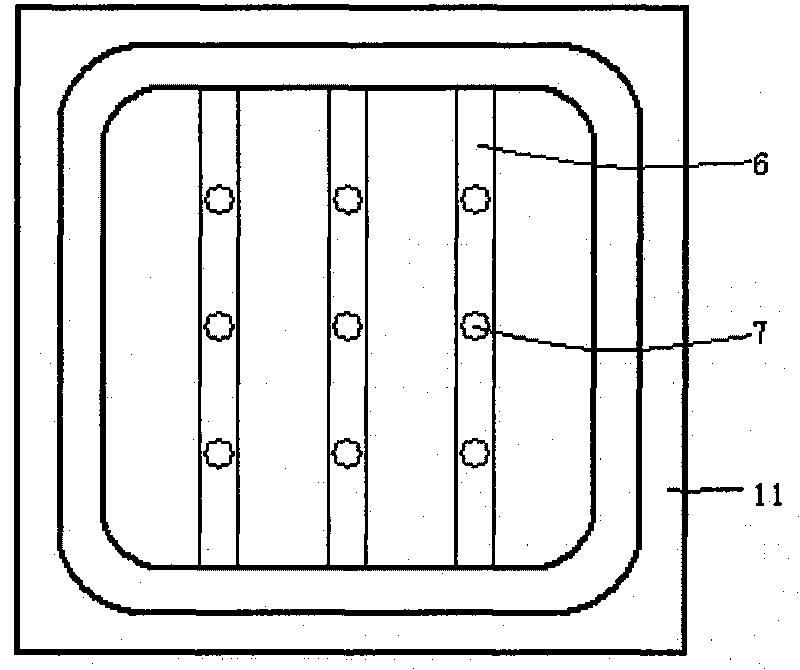

[0039] as attached figure 1 , attached figure 2 Shown is a schematic cross-sectional view and a top view of the first embodiment of the present invention.

[0040] The semiconductor device of the present invention includes: N-type substrate region 1, which is an N-type conductivity type semiconductor substrate material, and the cathode is drawn out through a metal on the lower surface of the substrate layer; N-type drift layer 2, which is an N-type conductivity type semiconductor material, is located On the N-type substrate region 1; the N-type depletion layer 3 is a semiconductor material of the N-type conductivity type, located on the N-type drift layer 2; the N-type heavily doped layer 4 is a semiconductor material of the N-type conductivity type, Located on the N-type depletion layer 3; the semiconductor material and metal on the top of the N-type heavily doped layer 4 form a Schottky barrier layer 5, and a layer of conductive metal is covered on the Schottky barrier lay...

Embodiment 2

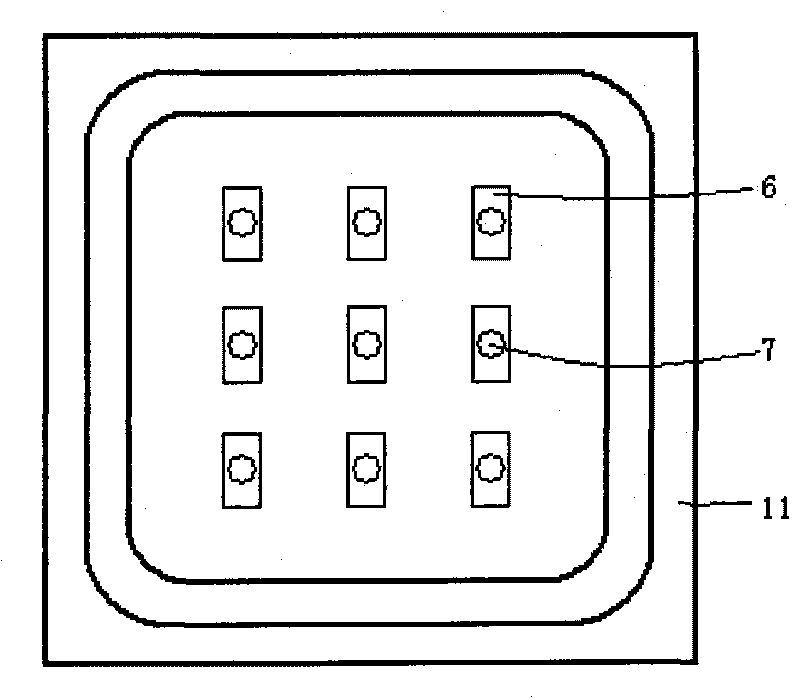

[0046] as attached image 3 As shown, nine strip-shaped reverse-bias leakage current suppression P-type regions 6 are separately formed in the N-type drift layer 2 and the N-type depletion layer 3, and the width of each reverse-bias leakage current suppression P-type region 6 is set The distance between two adjacent P-type regions 6 for suppressing reverse bias leakage current is 2-6um; nine small-area P-type regions 7 separated from each other are formed in the N-type heavily doped layer 4, each Two small-area P-type regions 7 are connected to corresponding reverse-bias leakage current suppressing P-type regions 6, the distance between two adjacent small-area P-type regions 7 is 2-20um, and the diameter of each small-area P-type region 7 circle is 1~5um; the phosphorus impurity concentration in the drift layer is 1×10 16 atom / cm 3 , the phosphorus impurity concentration in the depletion layer is chosen to be 1×10 15 atom / cm 3 , the concentration of phosphorus atoms doped ...

Embodiment 3

[0048] The structure and manufacturing process are as in Example 1, and the phosphorus impurity concentration in the drift layer is selected as 5×10 16 atom / cm 3 , the phosphorus impurity concentration in the depletion layer is chosen to be 5×10 15 atom / cm 3 , the concentration of doped phosphorus atoms in the substrate layer is selected as 1×10 20 atom / cm 3 , the phosphorus impurity concentration in the heavily doped layer is chosen to be 8×10 16 atom / cm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com