Schottky clamping diode with groove structure and terminal structure

A terminal structure and diode technology, applied in the field of electronics, can solve problems such as concentration, large voltage drop of oxide layer structure, weak withstand voltage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

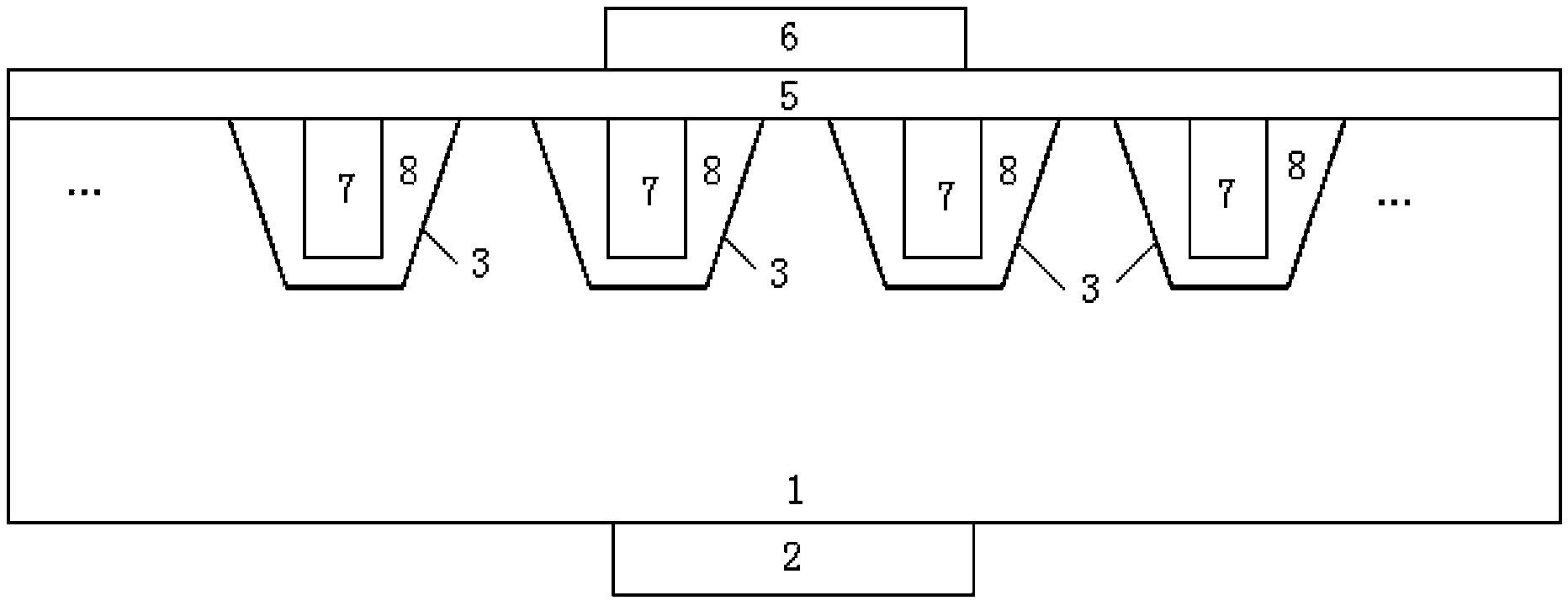

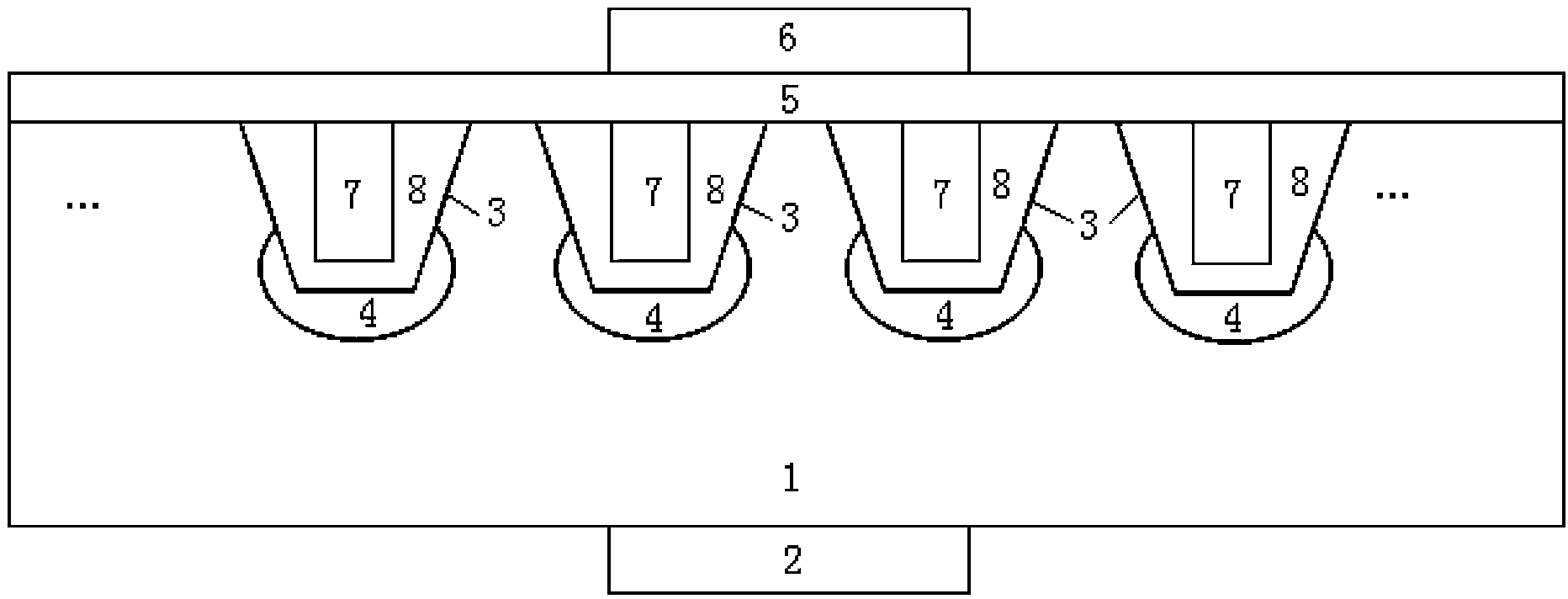

[0020] see image 3 As shown, in the following embodiments, taking N-type epitaxy as an example, the improved Schottky clamp diode with trench structure includes:

[0021] An N-type epitaxial layer 1 is used as the cathode 2 of the Schottky embedded diode with trench structure. The resistivity and thickness of the N-type epitaxial layer 1 are determined according to the reverse withstand voltage of the product itself.

[0022] A plurality of trenches 3 formed by an etching process in the N-type epitaxial layer 1 first grow a layer of first oxide layer 8 inside the trenches 3, and then fill them by thermal oxidation or CVD (chemical vapor deposition) Into the polysilicon 7, and finally form the trench region.

[0023] A P-type doped region (P well) 4 formed by ion implantation at the bottom of the trench 3, the P-type doped region 4 wraps the bottom of the trench 3, and each P-type doped region 4 is mutually will not be connected.

[0024] The metal layer 5 formed on the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com