Electrostatic discharge protection structure in semiconductor device and semiconductor device

An electrostatic discharge protection, semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problems of small withstand current, burnout of protective structure, etc., to achieve increased withstand current, reduced Rdson, On-resistance reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

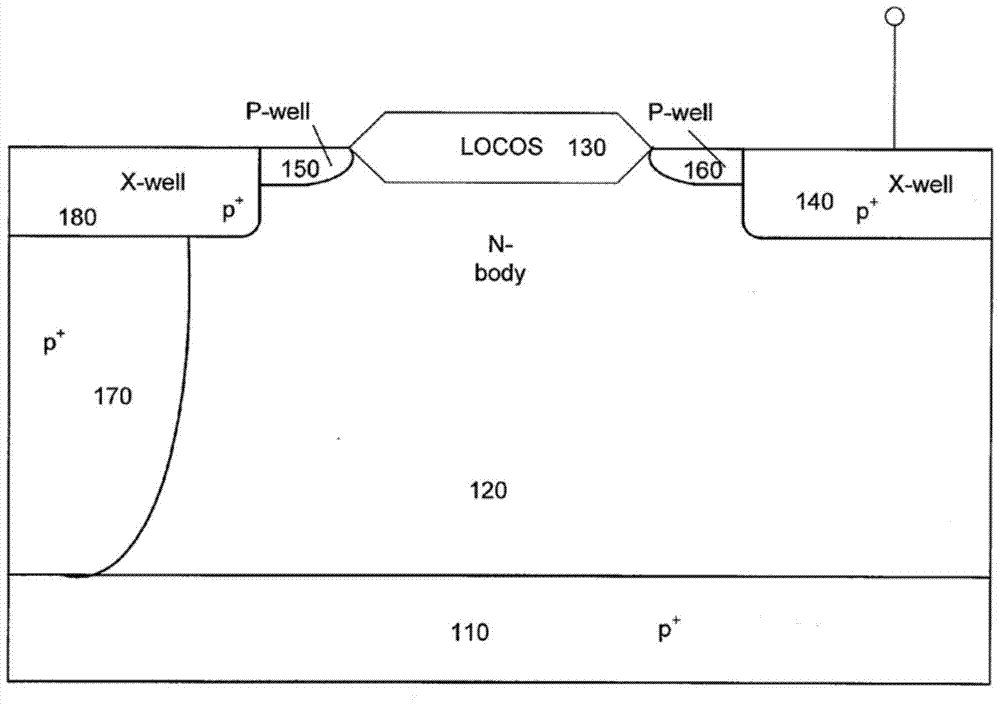

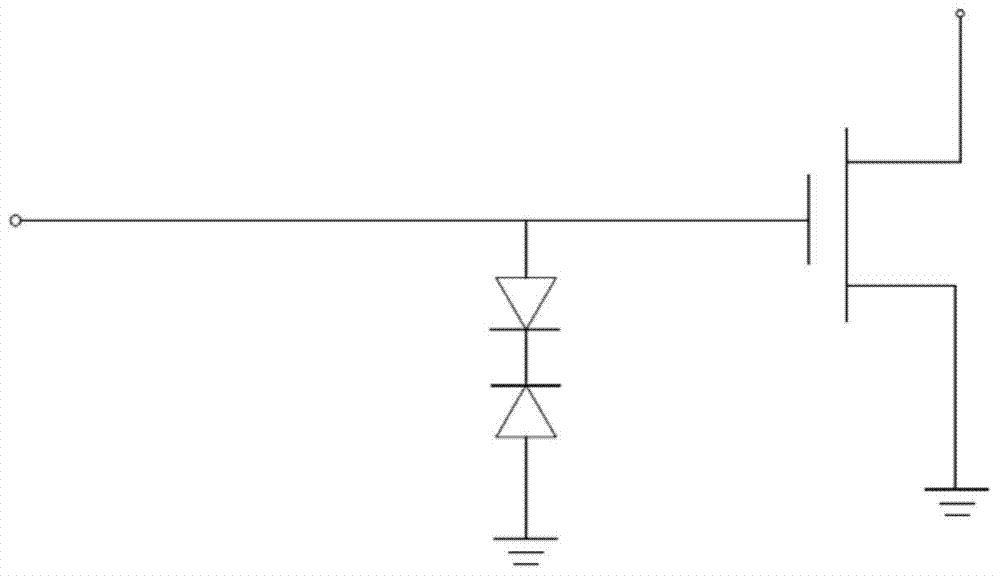

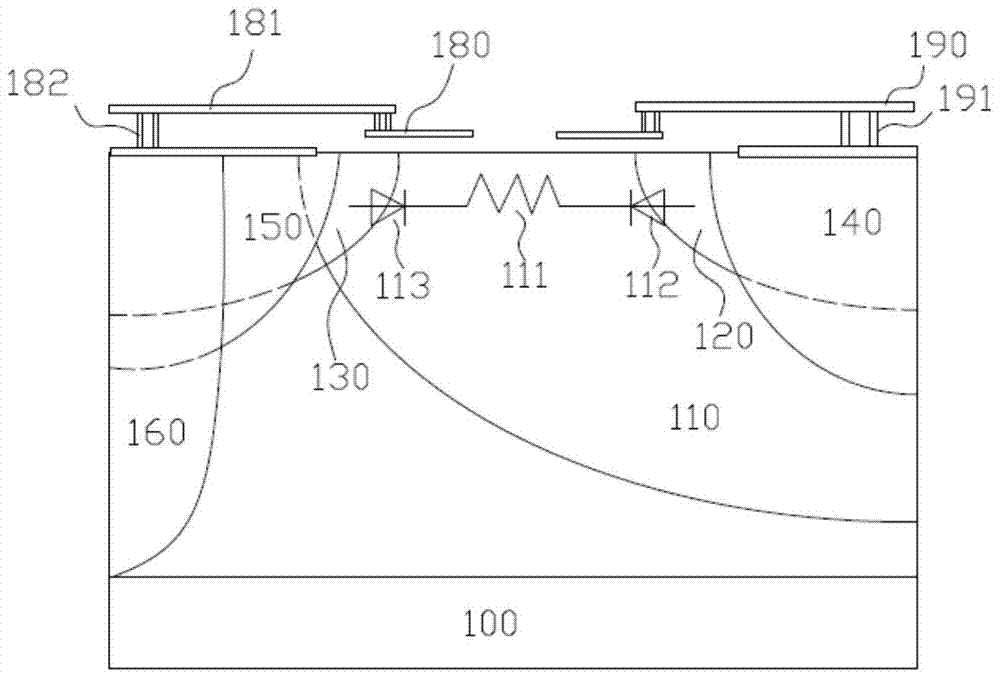

[0029] As mentioned in the background art, an existing ESD protection structure of a semiconductor device is realized by arranging a pair of back-to-back diodes. The working principle of this ESD protection structure is that when the externally applied voltage is greater than the breakdown voltage of one of the diodes, the ESD protection structure works in a conduction mode, and the external voltage is derived from the branch where the ESD protection structure is located. In this case, the breakdown voltage of each diode is proportional to the on-resistance Rdson when the structure turns on. In order to achieve the protection voltage required by the device, in the prior art, a thick field oxide layer is formed between the two P-well regions to increase the resistance value of Rdson, thereby increasing the breakdown voltage. However, this method of increasing the on-resistance will reduce the withstand current of the EDS protection structure, causing the ESD protection structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com