Efficient energy-saving Schottky diode

A Schottky diode and area technology, applied in the field of electronic information, can solve the problems of insufficiency of service life, large power loss, large reverse leakage, etc., to enhance reverse voltage withstand capability, reduce labor costs, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

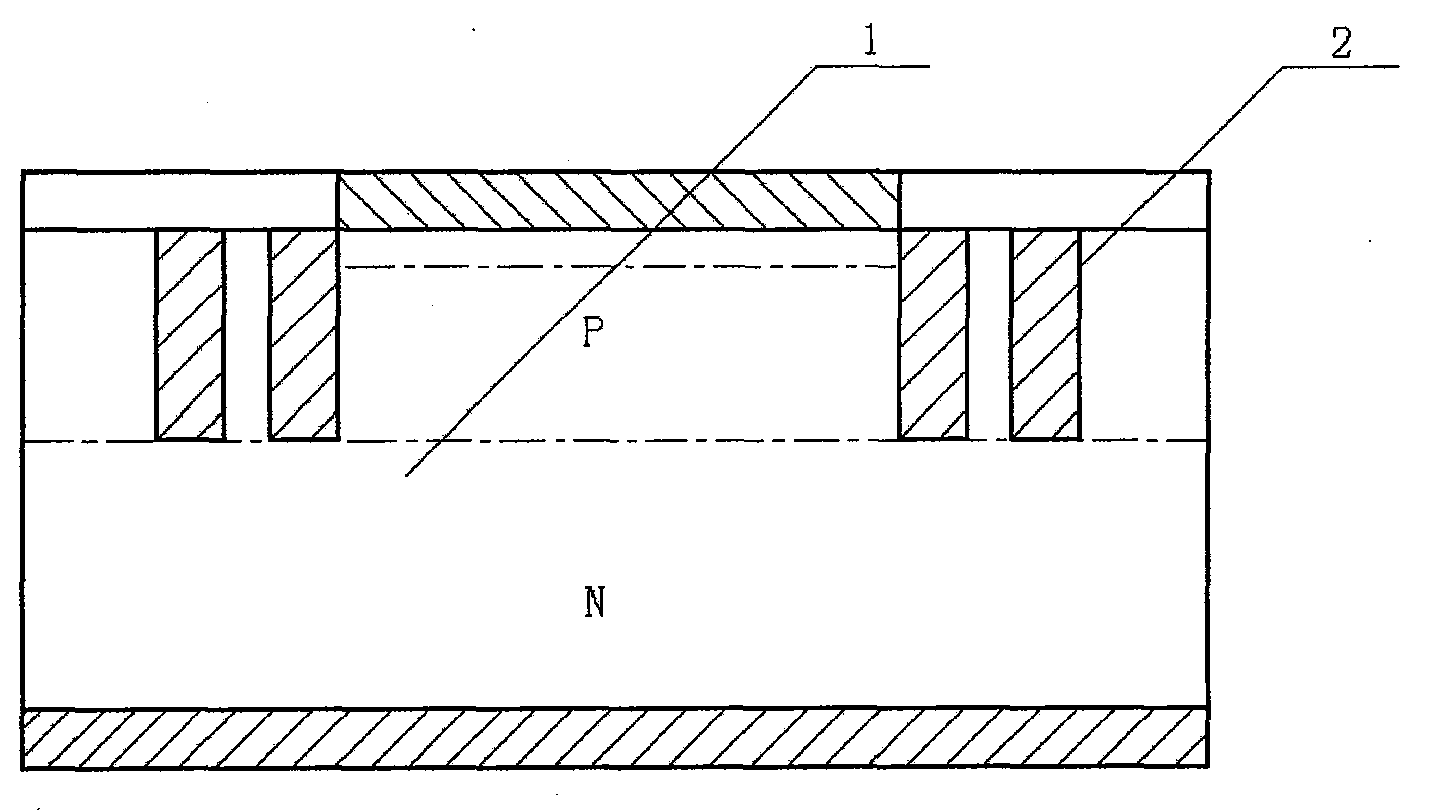

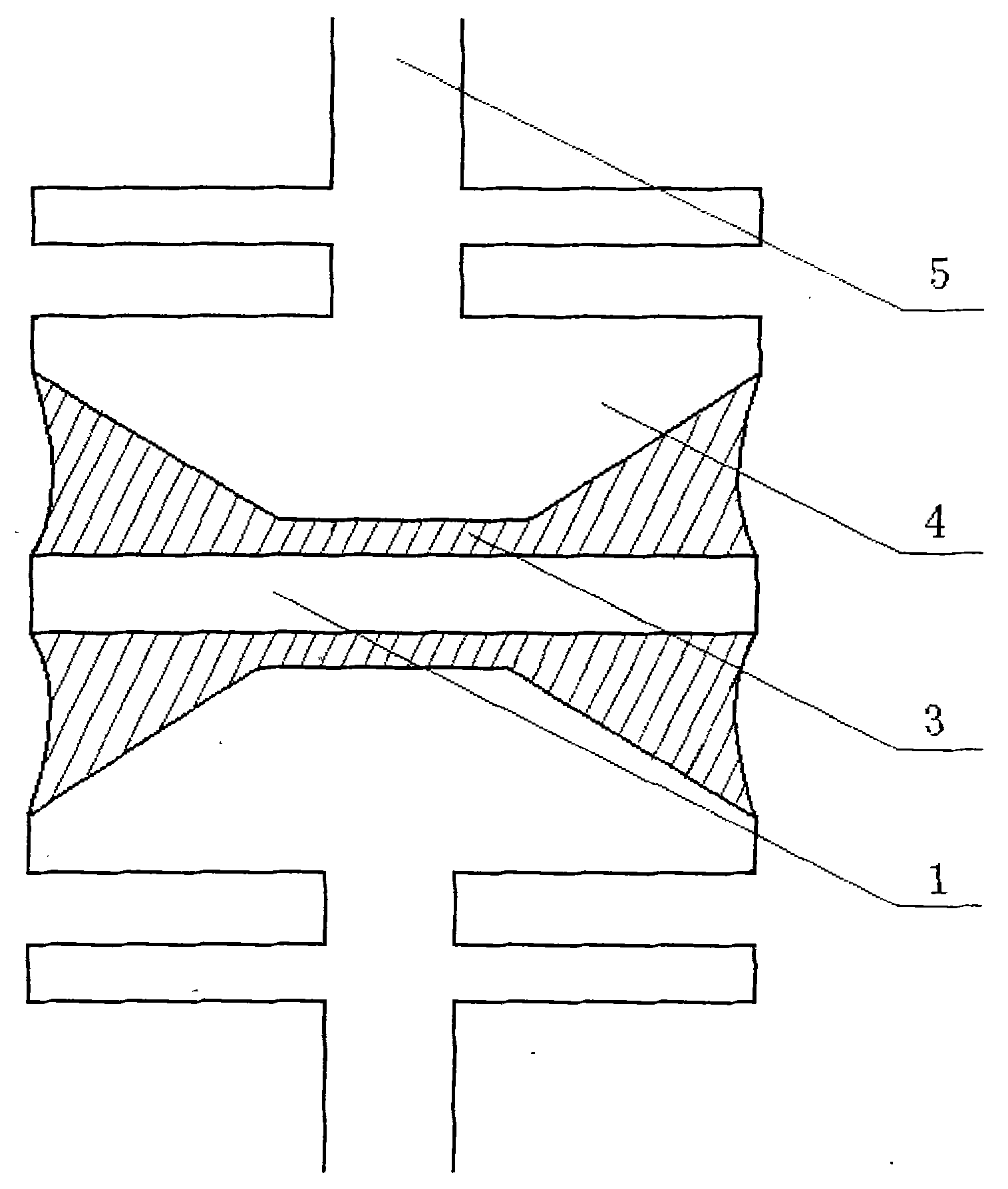

[0016] exist figure 1 In the shown embodiment, when a Schottky diode of the present invention diffuses a single crystal silicon wafer, a layer of composite elements is added to the P surface of a Schottky diode chip (1) as required and then sintered at high temperature to form a composite element interface layer The guard ring (2) improves the reverse insulation capability, so a Schottky diode of the present invention can overcome its defects and deficiencies while inheriting and developing the advantages of the existing Schottky diode, making a Schottky diode of the present invention The reverse leakage current of the diode is as small as ≤15μA, and the reverse withstand voltage capability is enhanced to ≥50V; usually in the production of traditional diodes, there are six processes of corrosion, conversion of sliver, gluing, baking, sintering, and packaging, and it takes eighteen However, a Schottky diode of the present invention saves the four processes of corrosion treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com