Photo thermal driving micro motor

A micro-motor and photothermal technology, which is applied to motors, generators/motors, and electrical components that apply thermal effects, can solve problems such as lack of mechanisms and methods for similar micro-miniature photothermal drive motors, and achieve a small step distance. , easy to miniaturize, structure independent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The invention adopts a research method combining laser technology, micro / nano technology and micro-special motor technology. The micro / nano-scale photothermal effect is used to cause thermal expansion of solid materials to directly drive the motor.

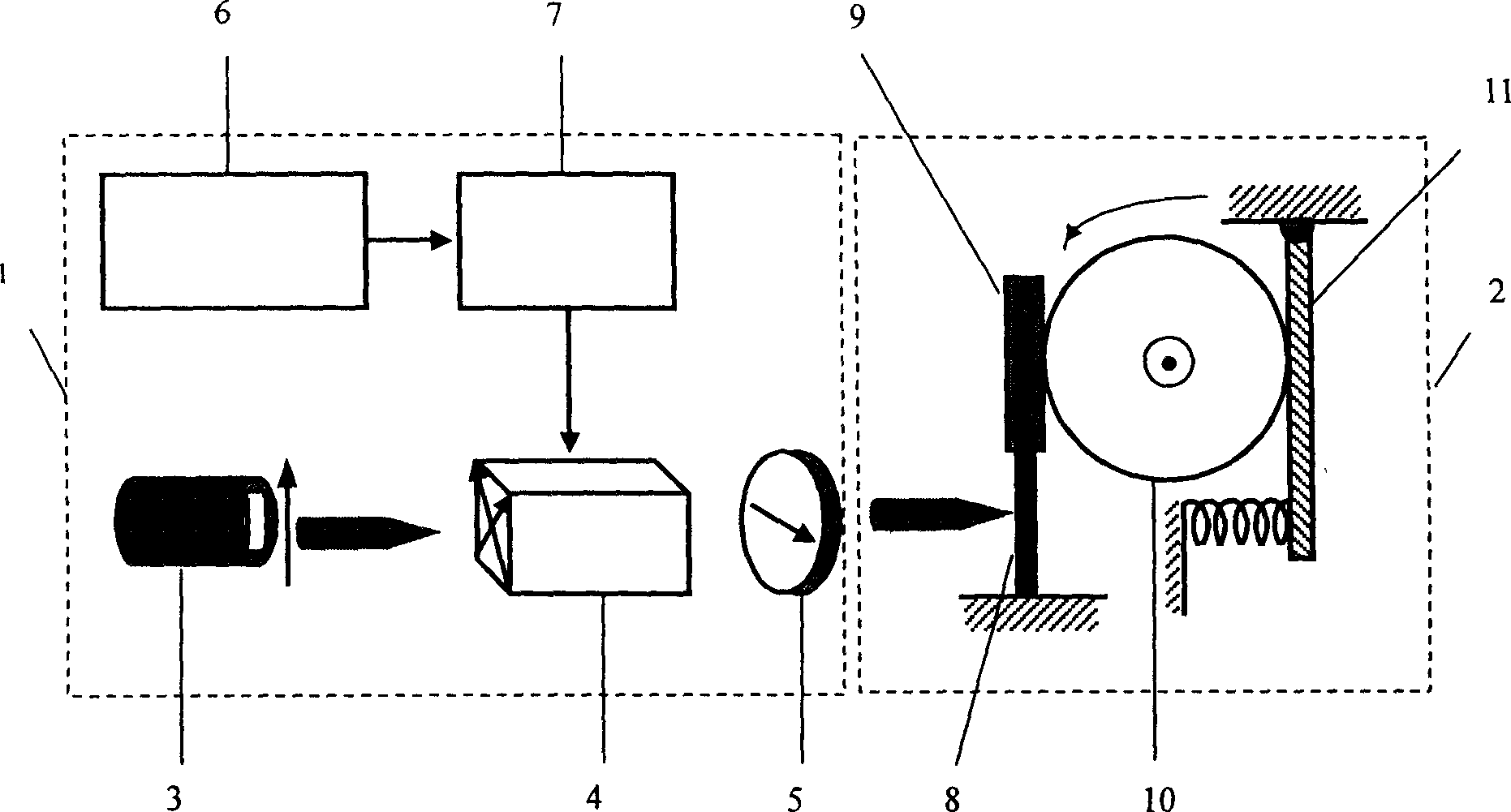

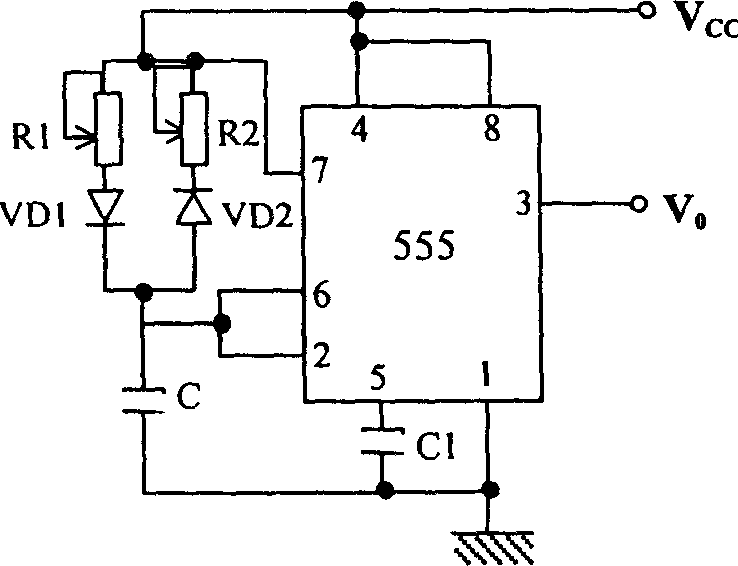

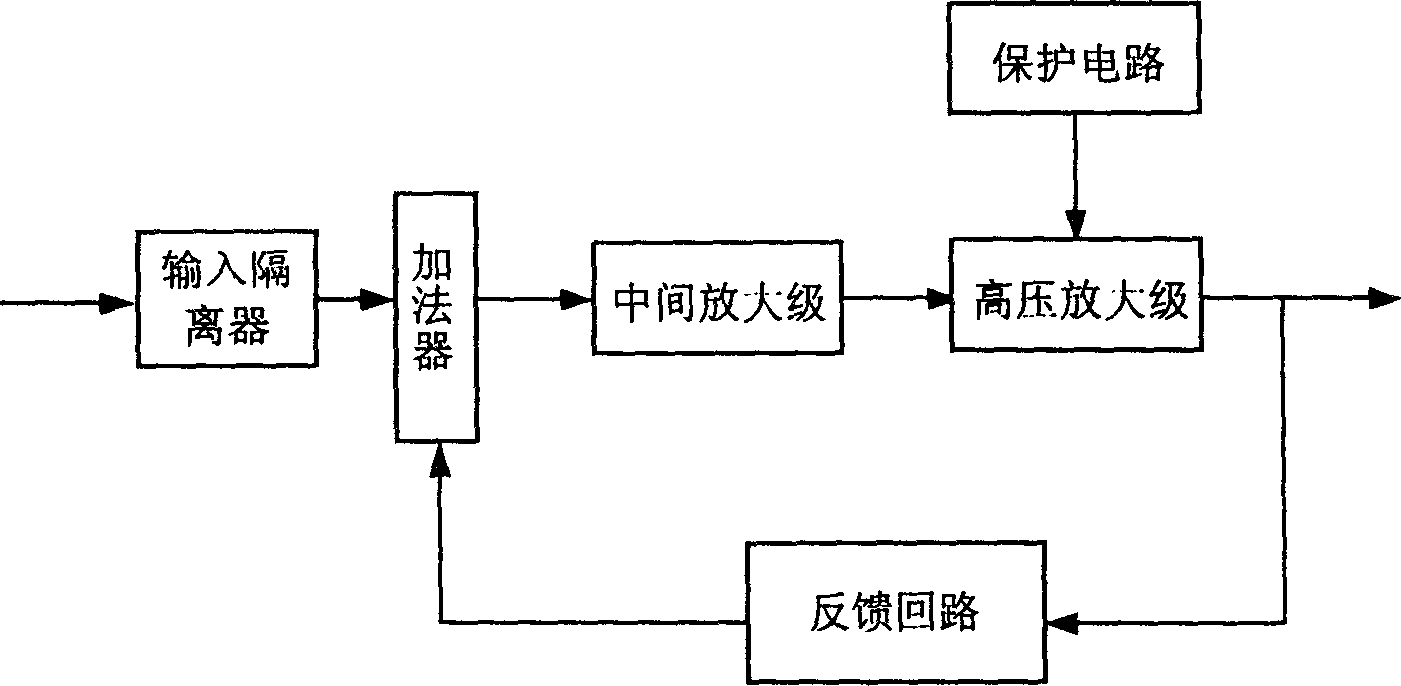

[0012] figure 1 As shown, the photothermal drive micromotor has a pulse light source system 1 and a rotation system 2. The pulse light source system 1 has a laser 3, an electro-optic crystal 4, and a polarizing disk 5 arranged in sequence. The electro-optic crystal 4 is composed of a pulse signal generation module 6 and an amplification circuit 7. Control, the rotation system 2 has an expansion arm 8, a friction plate 9, a coaxial rotor 10 and a pressure spring 11. One end of the expansion arm 8 is fixed, and the other end is bonded to the friction plate 9. One end of the pressure spring 11 is fixed, and the other end is fixed. It is connected with a spring, and the rotor 10 is connected with the pressure spring 11 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com