Power type LED lead frame piece and process technique thereof

A lead frame and power type technology is applied in the field of processing technology of the power type LED lead frame sheet, and can solve the problems of low productivity, high processing energy consumption, low processing energy consumption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

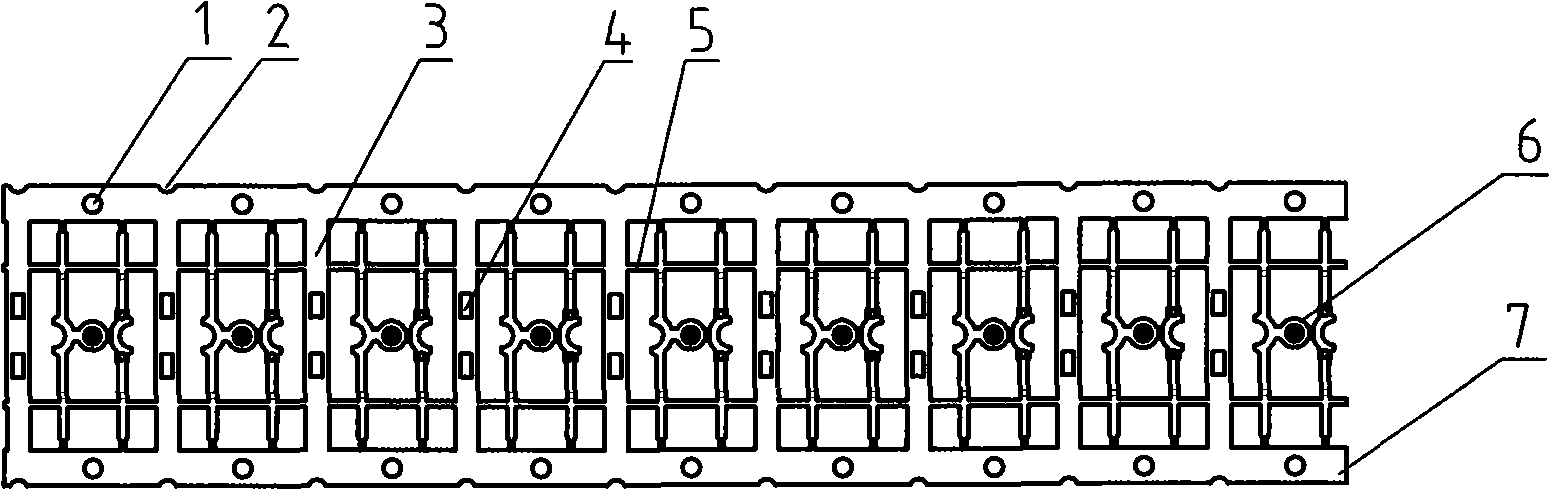

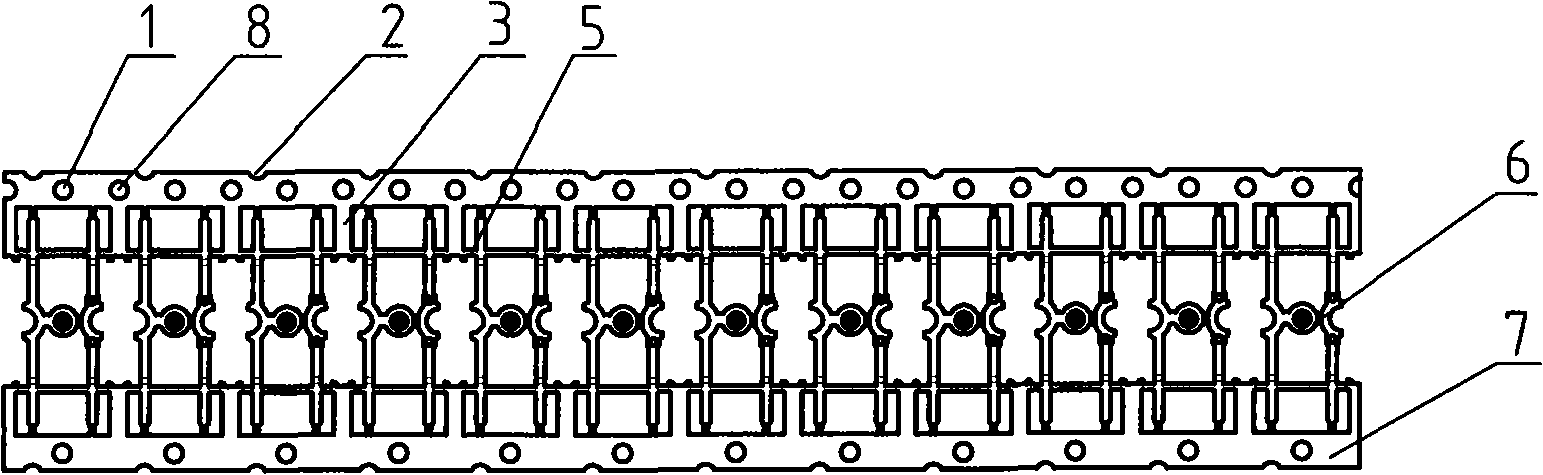

[0025] Refer to the attached figure 2 , the power type LED lead frame sheet of the present invention includes a lead frame 6, a frame 7 and a connecting rib 3, wherein a process hole 1 is arranged on the frame corresponding to the longitudinal centerline of the lead frame, and a process gap 2 is arranged on the outside thereof, and the connecting rib and the lead wire A horizontal connecting rib 5 is arranged between the frame pins, the step distance is 9.5 mm, and the width of the connecting rib 3 is 1.45 mm, and it is between the frame 7 and the horizontal connecting rib 5 on the corresponding side; The rib length is 1.05mm.

[0026] In order to facilitate identification of the processing orientation of the lead frame sheet in subsequent processing steps, an auxiliary process hole 8 is provided on one of the frames 7 corresponding to the ribs 3 , and the processing orientation can be identified according to the auxiliary process control.

[0027] Because of the addition of...

Embodiment 2

[0029] Refer to the attached figure 2 , LED lead frame sheet of the present invention, it is with respect to embodiment 1, and step distance adopts 9.6mm, and in fact the optimal solution of the present invention is that step distance adopts 9.525mm, and step distance cannot be too small, if too small, then finally every The design of the lead frame slitting die will be very difficult, and the arrangement and design of the connecting ribs and horizontal connecting ribs will also be difficult. The strength cannot be guaranteed, and the stiffness is relatively secondary here. However, if the step distance is too large, the structural waste will inevitably increase, which is not conducive to energy saving and consumption reduction, saving raw materials. Corresponding to the step distance of 9.6mm, the width of the connecting rib is 1.55mm, and the width of the connecting rib should consider the stiffness and strength requirements of the lead frame sheet, especially the rigidity....

Embodiment 3

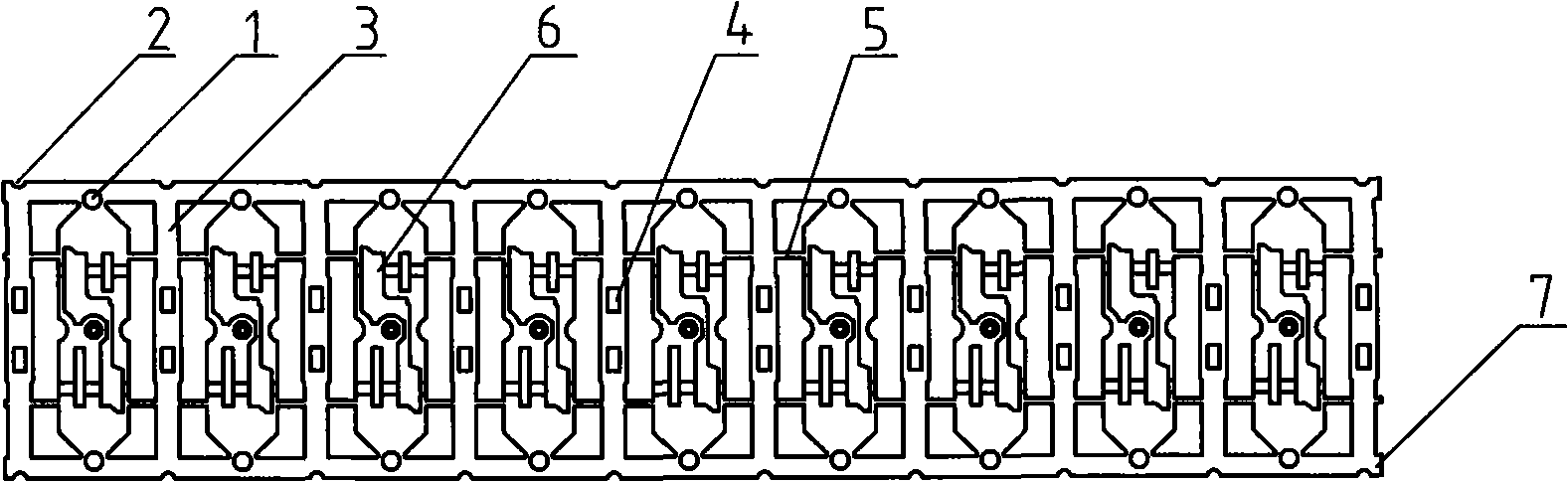

[0031] Refer to the attached Figure 4, this embodiment is mainly aimed at the SnapLED type lead frame sheet, because the structural strength of the lead frame itself is relatively high, so the setting of the connecting ribs is narrower than that of 1 and 2 in the implementation, but in order to balance the influence of the additional stress on the lead frame, The connecting rib part between the two horizontal connecting ribs is retained. Its step distance is exactly the same as that of Embodiments 1 and 2, which is 9.5 mm to 9.6 mm, and the width of the connecting rib 3 between the frame 6 and the horizontal connecting rib 5 is 0.95 mm to 1.05 mm, and it is between the The width of the portion between the two horizontal connecting ribs 5 is 0.48 mm to 0.5 mm; the length of the horizontal connecting ribs is 1.23 mm to 1.33 mm, and the selection of the length and width of the connecting ribs is also consistent with the above-mentioned embodiment.

[0032] The present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com