Ultrasonic preparation method of peanut protein/polysaccharide composite particle and functional food application

A technology of peanut protein and composite particles, which is applied in the direction of medical preparations containing active ingredients, applications, food ingredients, etc., can solve the problems of poor aggregation effect and low embedding efficiency of bioactive ingredients, and achieve long and stable sustained release time Good performance and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

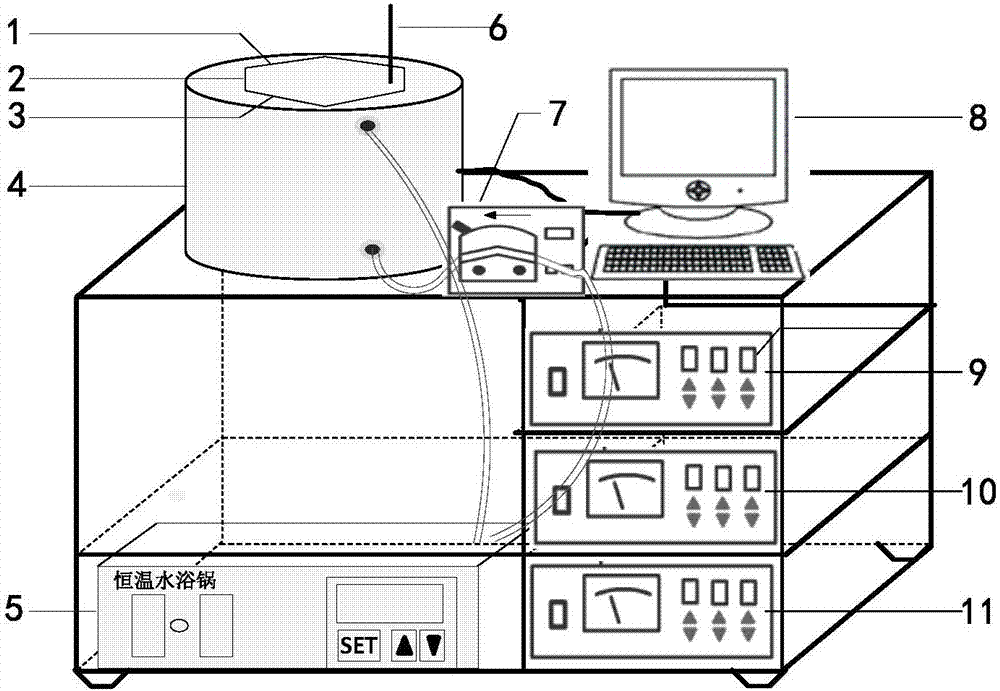

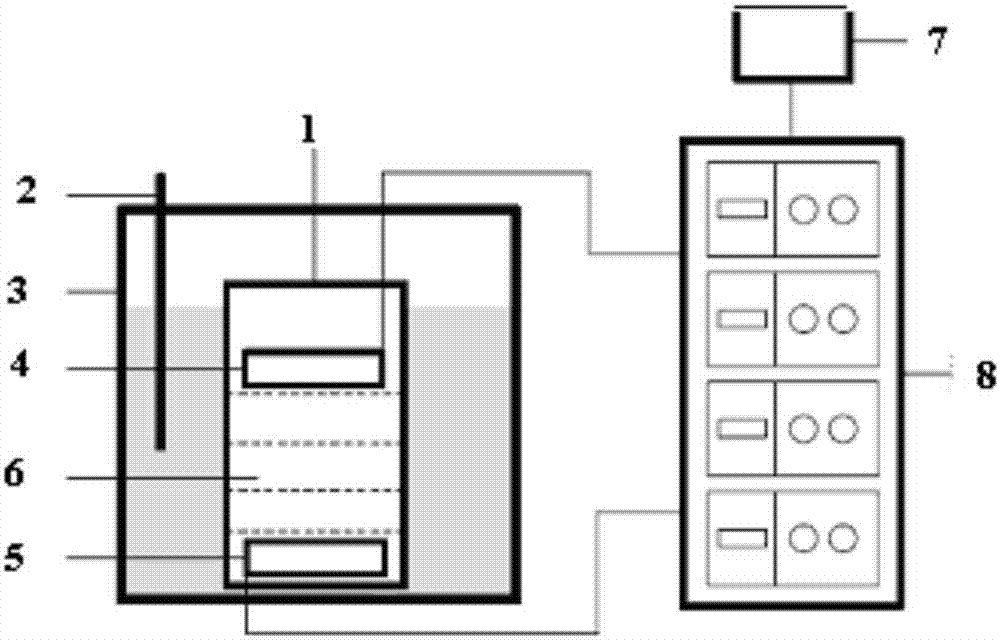

Method used

Image

Examples

Embodiment 1-6

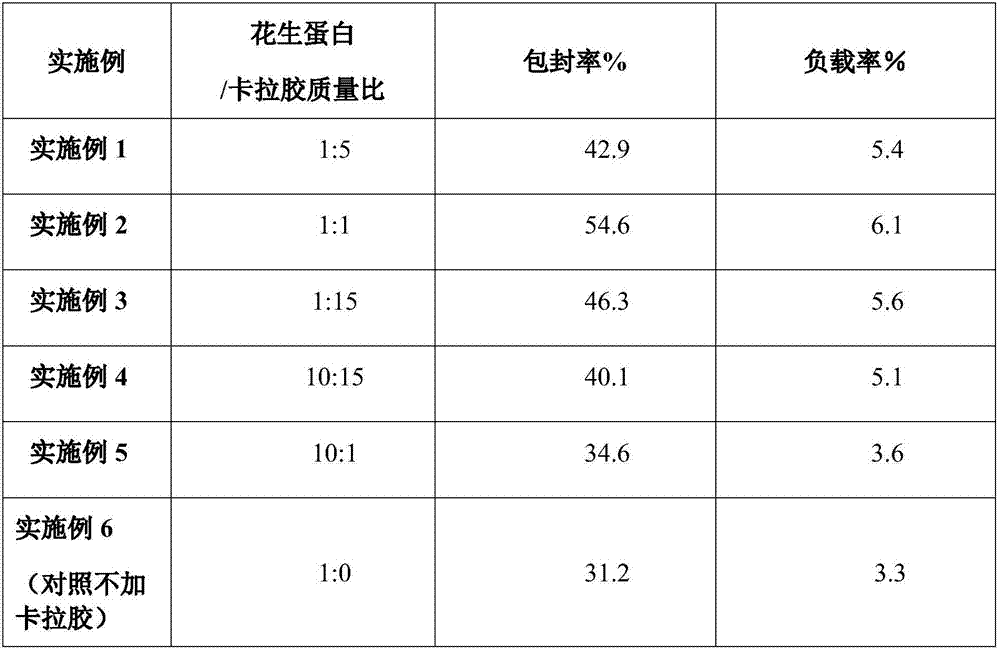

[0068] Embodiment 1-6 (do not add ultrasonic)

[0069] The preparation method of peanut protein-carrageenan composite particle loaded tea polyphenols is carried out according to the following steps:

[0070] (1) Dissolve the peanut protein in distilled water, and magnetically stir until the protein is completely dissolved; obtain a solution with a peanut protein concentration of (1-10) mg / mL;

[0071] (2) Dissolve κ-carrageenan into the aqueous solution, and magnetically stir until completely dissolved; obtain a carrageenan solution with a concentration of (1-15) mg / mL;

[0072] (3) The carrageenan solution in step (2) is added dropwise to the peanut protein solution in step (1) in a ratio of 1:1 by volume, so that the mass ratio of peanut protein and carrageenan is shown in Table 1, and then the mixed solution is adjusted pH=5.

[0073] (4) adding a certain amount of tea polyphenols into the peanut protein and carrageenan composite particle solution prepared in step (3), so...

Embodiment 7-10

[0084] Embodiment 7-10 (frequency-sweeping dual-frequency ultrasonic treatment)

[0085] Peanut protein: 10 parts;

[0086] Carrageenan: 15 parts.

[0087] The preparation method of peanut protein-carrageenan composite particle loaded tea polyphenols is carried out according to the following steps:

[0088](1) Dissolve the peanut protein in distilled water, and magnetically stir until the protein is completely dissolved; obtain a solution with a peanut protein concentration of 10 mg / mL;

[0089] (2) Dissolving the iota-type carrageenan in the aqueous solution, magnetically stirring until completely dissolved; obtaining a concentration of 15mg / mL carrageenan solution;

[0090] (3) Add the carrageenan solution in step (2) dropwise to the peanut protein solution in step (1) in a ratio of 1:1 by volume, so that the mass ratio of peanut protein and carrageenan is 10:15, and then adjust the mixed solution pH=5.

[0091] (4) adding a certain amount of tea polyphenols into the pea...

Embodiment 11-14

[0103] Embodiment 11-14 (multi-mode frequency ultrasonic treatment)

[0104] Peanut protein: 10 parts;

[0105] Carrageenan: 15 parts.

[0106] The preparation method of peanut protein-carrageenan composite particle loaded tea polyphenols is carried out according to the following steps:

[0107] (1) Dissolve the peanut protein in distilled water, and magnetically stir until the protein is completely dissolved; obtain a solution with a peanut protein concentration of 10 mg / mL;

[0108] (2) Dissolving λ-type carrageenan in the aqueous solution, magnetically stirring until completely dissolved; obtaining a carrageenan solution with a concentration of 15 mg / mL;

[0109] (3) Add the carrageenan solution in step (2) dropwise to the peanut protein solution in step (1) in a ratio of 1:1 by volume, so that the mass ratio of peanut protein and carrageenan is 10:15, and then adjust the mixed solution pH=5.

[0110] (4) adding a certain amount of tea polyphenols into the peanut protei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com