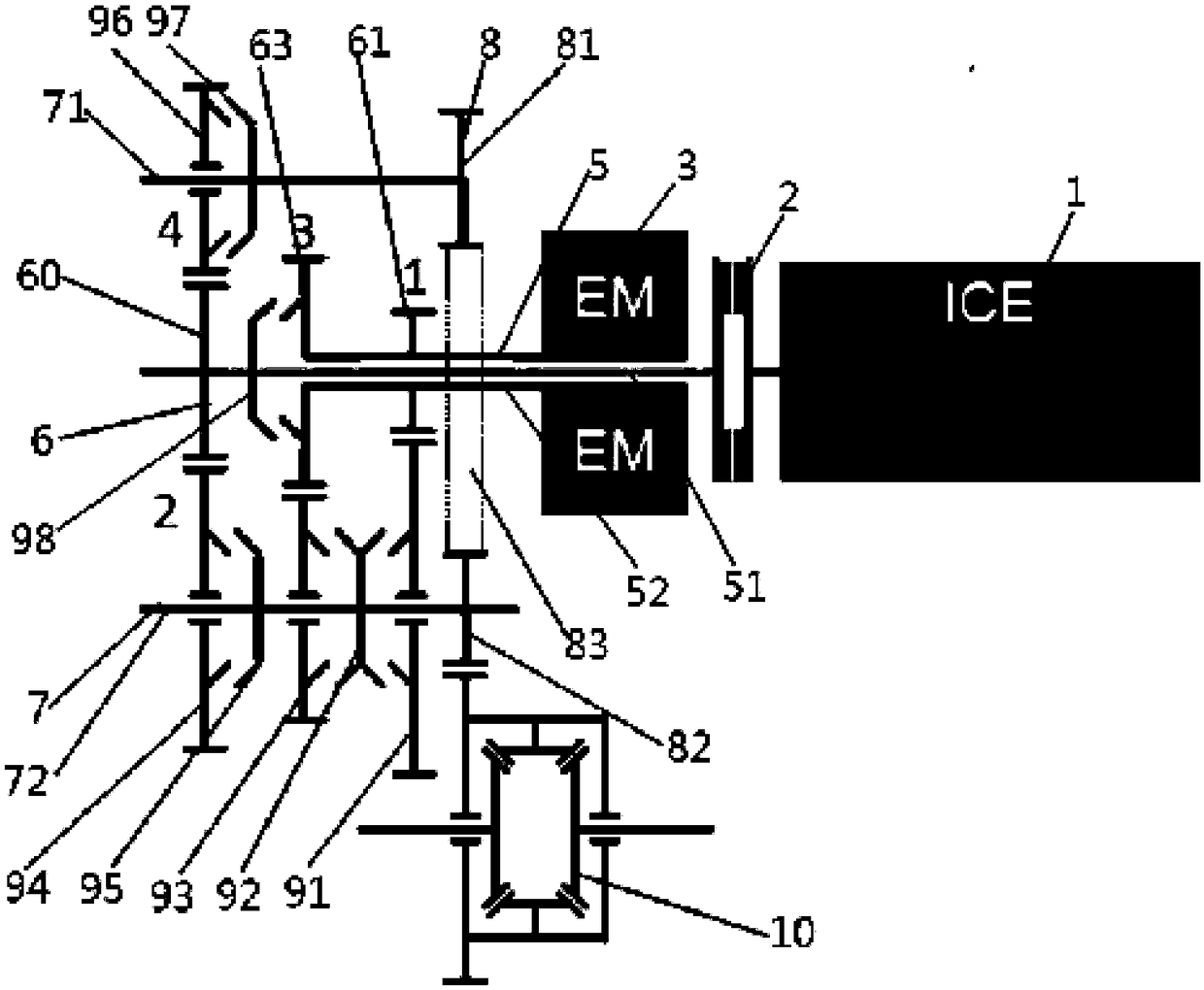

Hybrid power transmission system with dual gear structure

A double gear, hybrid technology, applied in the direction of gear transmission, components with teeth, transmission components, etc., can solve the problem that can not well meet the requirements of power and economy, the development limit of pure electric cars, can not meet the Emission regulations and other issues, to achieve the effect of being conducive to vehicle loading, good dynamic performance and economic indicators, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments are not limited to the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included within the protection scope of the present invention.

[0033] Such as figure 1 As shown, the present invention discloses a hybrid power transmission system with a dual gear structure, at least comprising an engine 1 and an electric motor 3, both of which are connected to a battery (not shown in the figure), and used in the vehicle system When the engine is running, the car is idling, or the power output of the engine 1 is too much, the engine 1 can be used as a generator, and this part of energy is recovered and stored in the battery in the form of electric energy, so that it can be used when needed. The motor 3 is output in the form of power. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com