Novel elastic stirring blade for concrete hopper

A mixing blade and concrete technology, which is applied in the field of mechanical mixing mechanism, can solve the problems of insufficient mixing of concrete and achieve the effects of simple structure, low cost and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

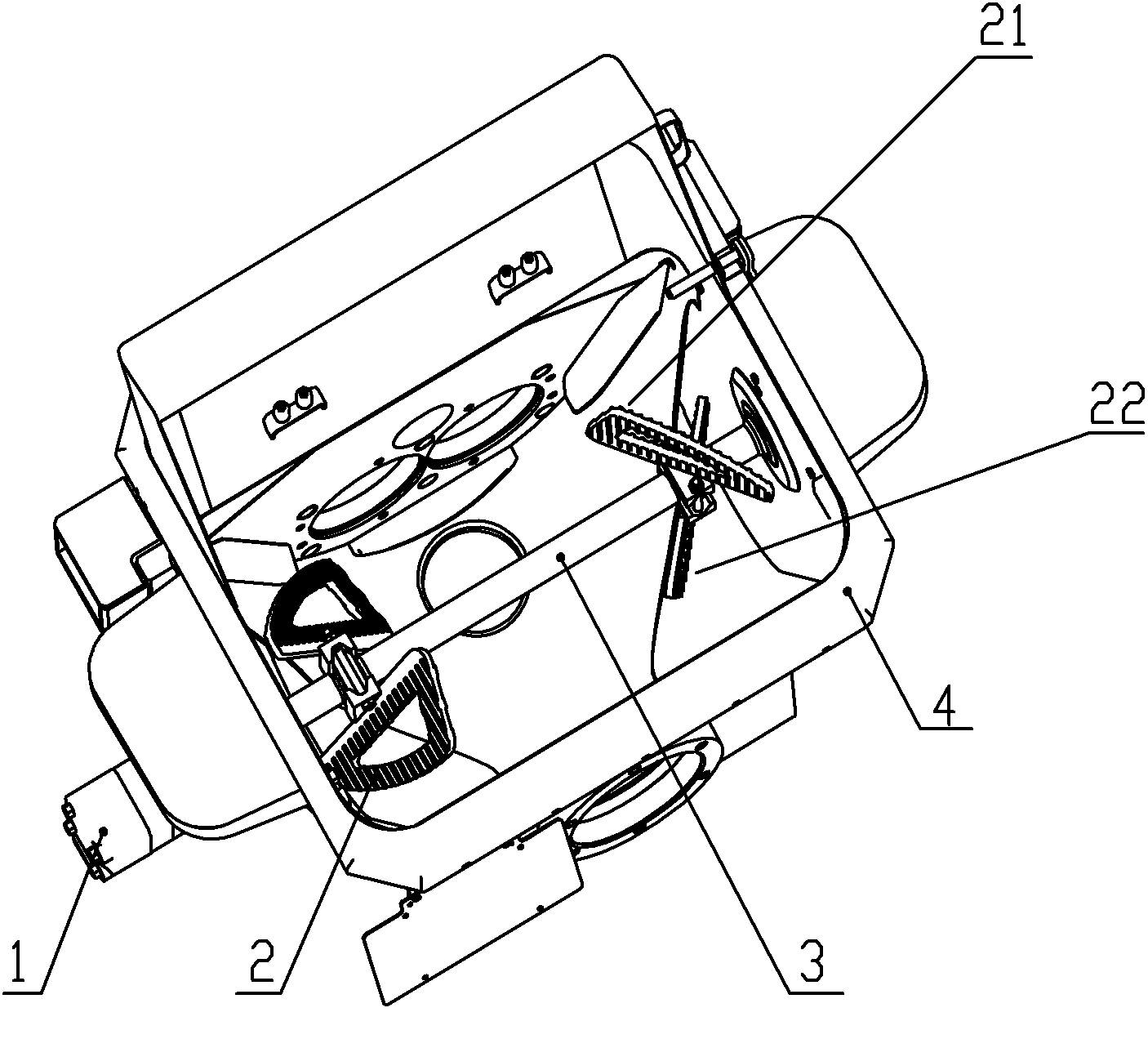

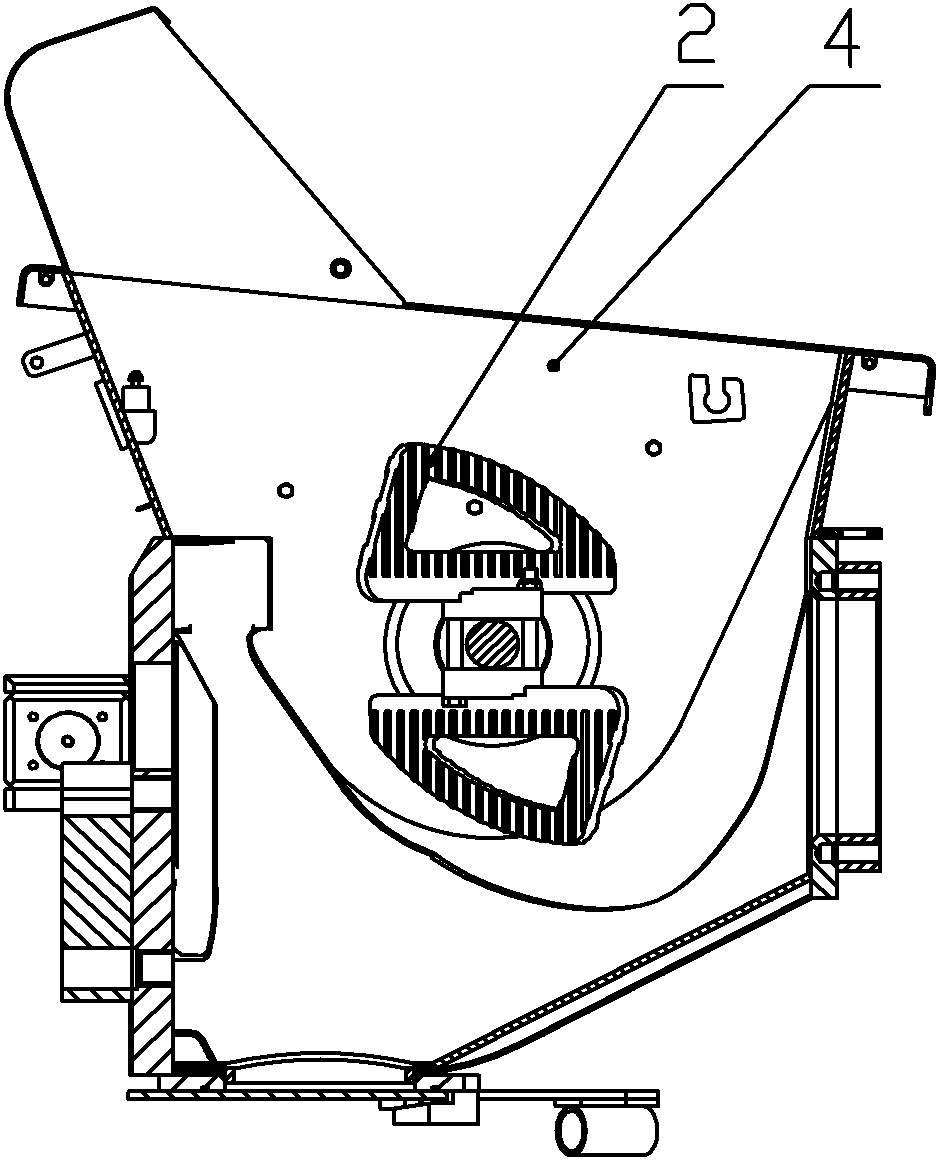

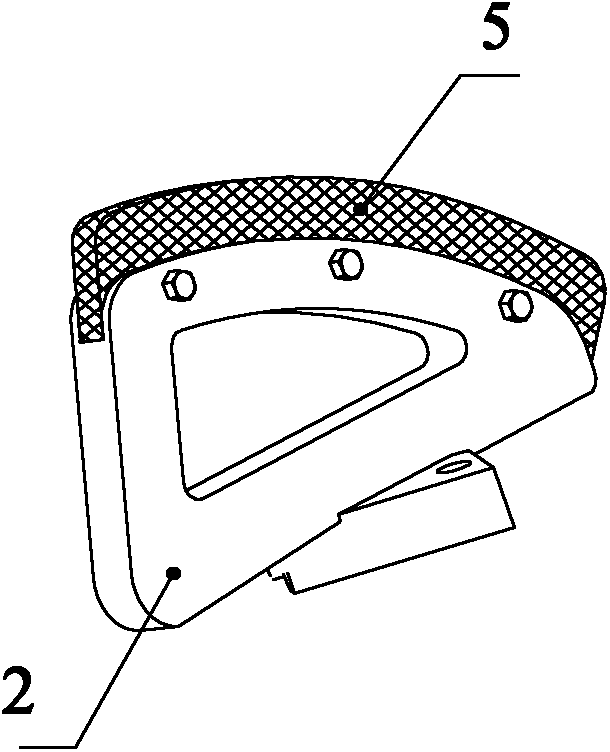

[0030] see figure 1 , figure 2 with image 3 , which shows an embodiment of the present invention's novel elastic stirring blades for concrete hoppers, the concrete hopper 4 is provided with a stirring shaft 3 driven by the stirring motor 1, and the stirring blades 2 are arranged on the stirring shaft 3 , and the mixing blade 2 is provided with an elastic flange 5 at least on the outer edge facing the concrete hopper 4, preferably, the elastic flange 5 is made of elastic non-metallic materials, such as polyurethane or wear-resistant rubber and other elastic non-metallic materials; the minimum distance between the elastic flange 5 and the concrete hopper 4 is 5-20 mm.

[0031] The stirring blade of the present invention can comprise blades of various shapes such as helical shape, in this embodiment, as image 3 As shown, the elastic flange 5 is a strip-shaped flange structure, that is, a continuous elastic non-metallic material flange structure is provided on the outer edge...

Embodiment 2

[0036] see figure 1 , figure 2 , Figure 4 with Figure 5 , which shows another preferred embodiment of the invention. The difference between this embodiment and the above embodiments is that the stirring blade 2 includes at least a first stirring blade 21 and a second stirring blade 22 arranged in pairs on the stirring shaft 3 . Further, the elastic flange 5 is a toothed flange structure arranged at intervals, such as Figure 4 with Figure 5 shown. Preferably, the gap between the elastic flange 51 on the first stirring blade 21 and the elastic flange 52 on the second stirring blade 22 and the tooth-shaped flanges are in complementary positions in space. More preferably, the gap between the elastic flanges is 25-40 mm.

[0037] Specifically, the present embodiment sets discontinuous (such as zigzag or wave-shaped, etc.) elastic non-metallic materials (such as polyurethane, wear-resistant rubber) on the outer edge of the metal stirring blade 2, see Figure 4 with Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com