Continuous rotary mixer and using method thereof

A mixer and drum technology, applied in the field of material mixing equipment, can solve the problems of poor mixing uniformity, wear and power consumption, and inability to continue production, and achieve the effect of convenient production, low cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

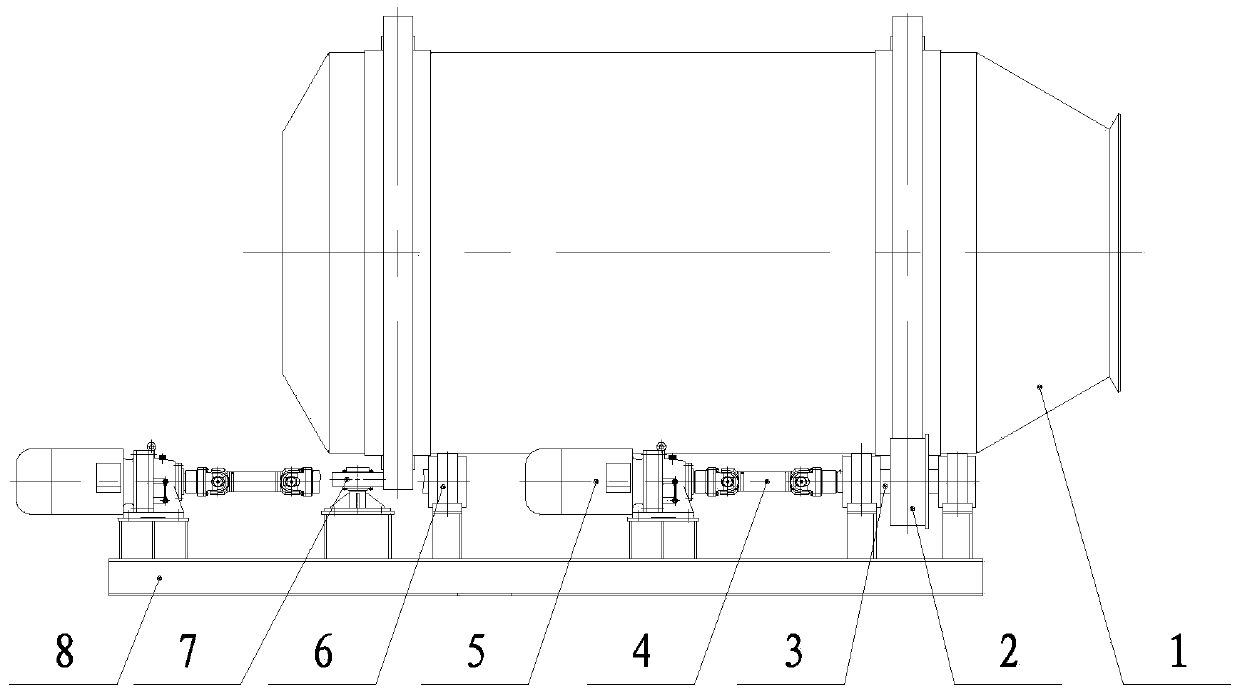

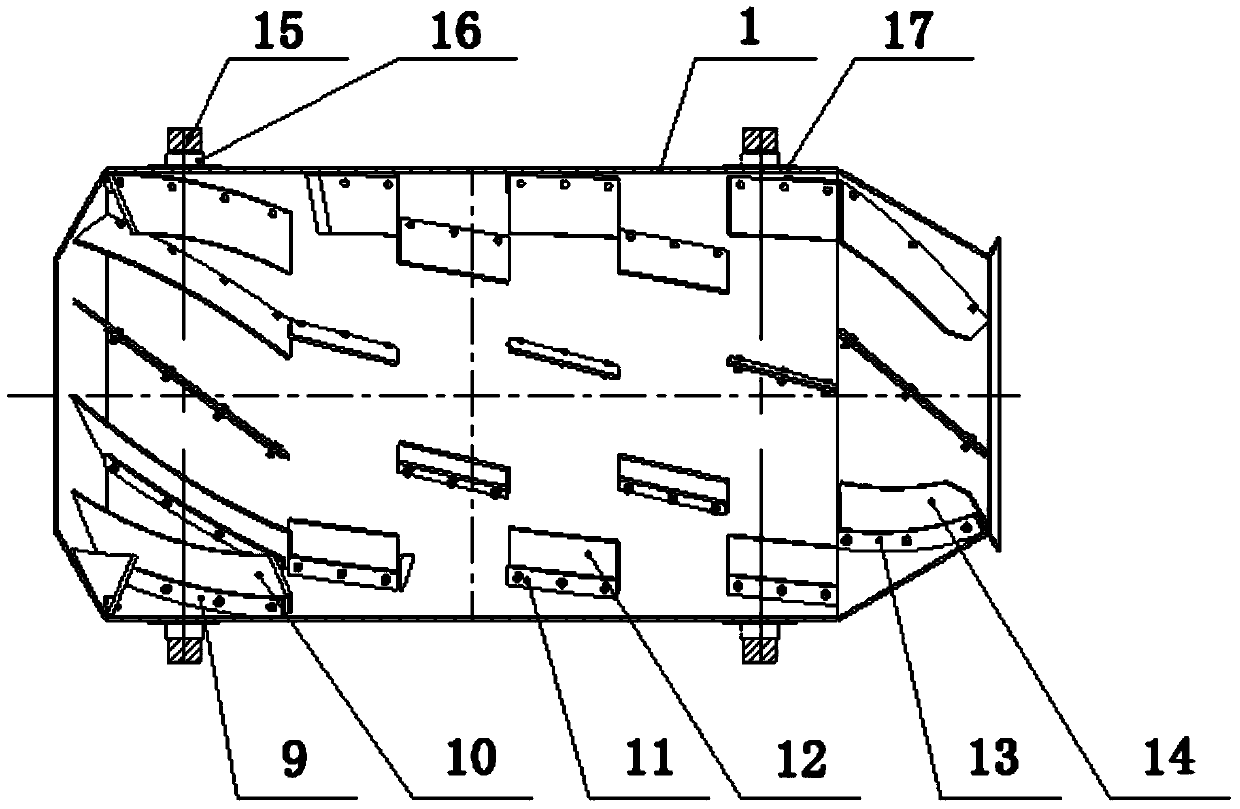

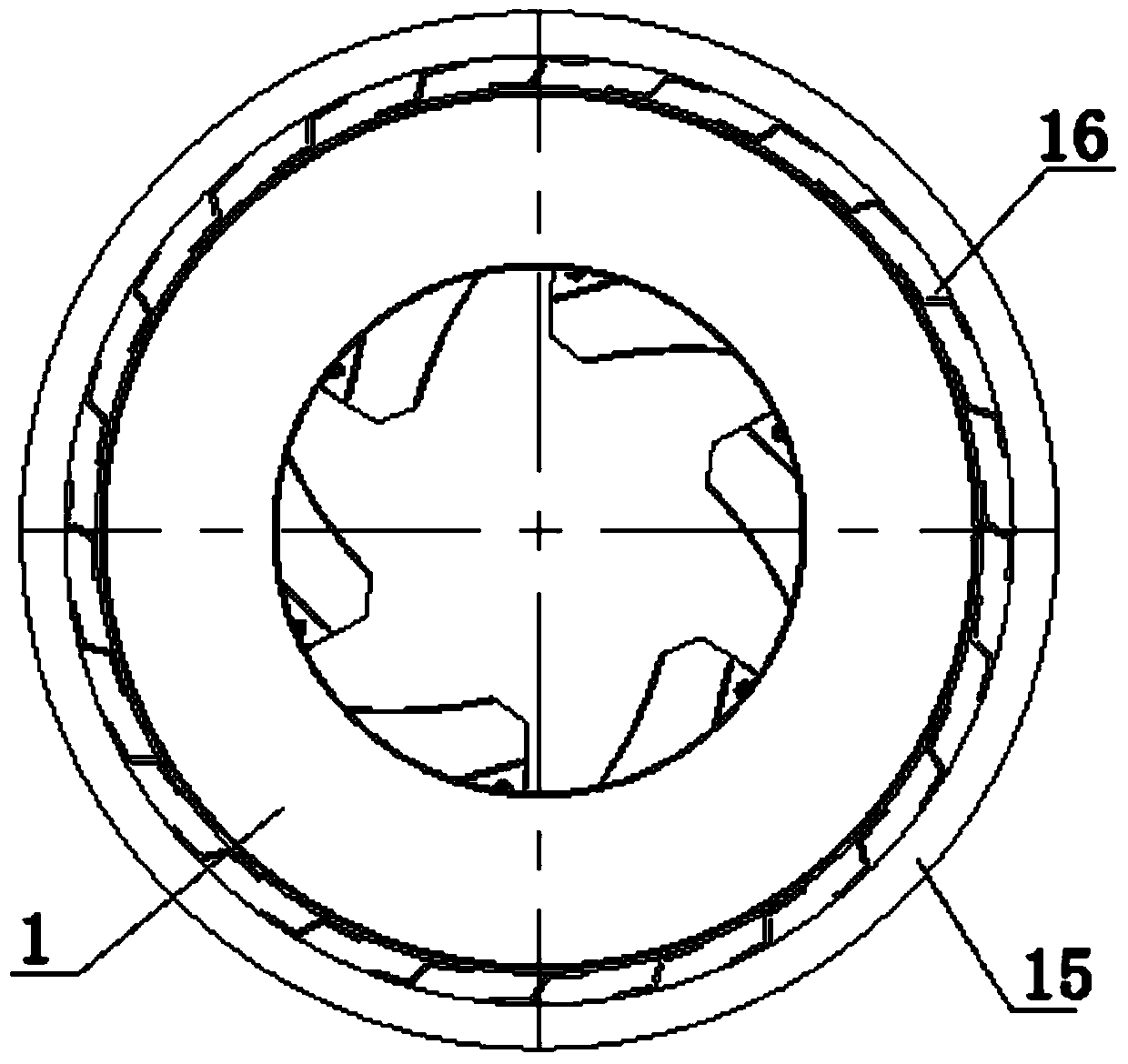

[0018] See Figure 1-Figure 3 , Continuous drum mixer, including base 8, cylinder 1, supporting wheel 2, transmission shaft 3, reducer 5, blocking wheel 7, wheel belt 15, Z-shaped plate 16, and a reinforcement ring 17 is fixedly connected to the outer wall of cylinder 1 , the belt 15 is fixed by the Z-shaped plate 16 uniformly fixed on the reinforcing ring 17; the transmission shaft 3 is fixedly connected with a supporting wheel 2, and the supporting wheel 2 abuts on the belt 15, driving the cylinder 1 to rotate around its central axis , the transmission shaft 3 is driven by the reducer 5 through the coupling 4, and the coaxiality is adjusted through the coupling 4; the retaining wheel 7 fixed on the base 8 abuts on the side wall of the wheel belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com