Granular southern paddy field acid soil conditioner using rice husk as matrix

An acid soil, granular technology, applied in soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve the problems of not being able to fundamentally regulate the acid soil of paddy fields, and not be able to supplement effective silicon, and achieve the benefits of root activity and efficiency. The effect of absorbing nutrients, increasing soil porosity, strong water absorption and water retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

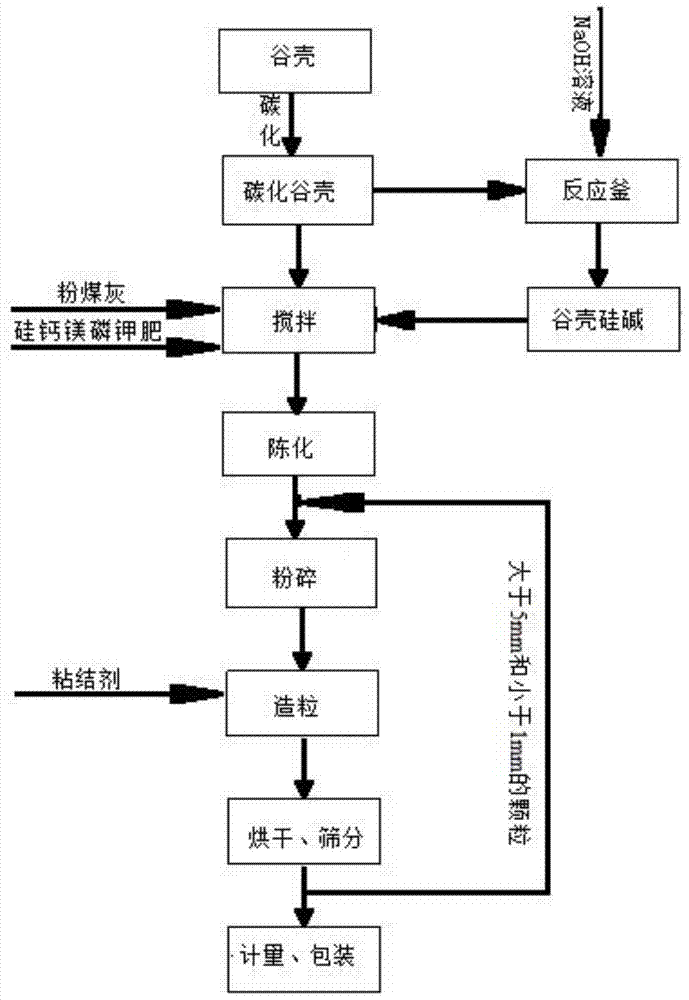

Method used

Image

Examples

Embodiment 1

[0040] The present embodiment provides a granular acidic soil conditioner for paddy fields in the south with rice husk as the substrate, and its raw material components include:

[0041] Carbonized chaff, 33 parts by weight;

[0042] Rice husk silica, 12 parts by weight;

[0043] Fly ash, 15 parts by weight;

[0044] Silicon calcium magnesium phosphorus potassium fertilizer, 30 parts by weight;

[0045] Anionic polyacrylamide (molecular weight is 3,000,000), 2 parts by weight;

[0046] Attapulgite powder, 2 parts by weight;

[0047] Wherein, described carbonized chaff adopts following method to prepare:

[0048] carbonize the chaff at 500°C for 6 hours, ventilate and cool to room temperature to obtain the carbonized chaff;

[0049] Described chaff silicon alkali adopts following method to prepare:

[0050] Adding a concentration of 20wt% NaOH solution to the carbonized chaff in the reaction kettle, controlling the mass ratio of the carbonized chaff to the sodium hydroxid...

Embodiment 2

[0055] The present embodiment provides a granular acidic soil conditioner for paddy fields in the south with rice husk as the substrate, and its raw material components include:

[0056] Carbonized chaff, 30 parts by weight;

[0057] Rice husk silica, 12 parts by weight;

[0058] Fly ash, 18 parts by weight;

[0059] Silicon calcium magnesium phosphorus potassium fertilizer, 27 parts by weight;

[0060] Anionic polyacrylamide (molecular weight is 4,000,000), 7 parts by weight;

[0061] Bentonite, 6 parts by weight;

[0062] Wherein, described carbonized chaff adopts following method to prepare:

[0063] Carbonize the chaff at 600°C for 4 hours, ventilate and cool to room temperature to obtain the carbonized chaff;

[0064] Described chaff silicon alkali adopts following method to prepare:

[0065] Adding a concentration of 10wt% NaOH solution to the carbonized chaff, controlling the mass ratio of the carbonized chaff to the sodium hydroxide solution to be 1:5, boiling an...

Embodiment 3

[0070] The present embodiment provides a granular acidic soil conditioner for paddy fields in the south with rice husk as the substrate, and its raw material components include:

[0071] Carbonized chaff, 38 parts by weight;

[0072] Rice husk silica, 10 parts by weight;

[0073] Fly ash, 17 parts by weight;

[0074] Silicon calcium magnesium phosphorus potassium fertilizer, 24 parts by weight;

[0075] Anionic polyacrylamide (molecular weight is 4.5 million), 4 parts by weight;

[0076] Bentonite, 10 parts by weight;

[0077] Wherein, described carbonized chaff adopts following method to prepare:

[0078] Carbonize the chaff at 550°C for 5 hours, ventilate and cool to room temperature to obtain the carbonized chaff;

[0079] Described chaff silicon alkali adopts following method to prepare:

[0080] Add NaOH solution with a concentration of 7wt% to the carbonized chaff, control the mass ratio of the carbonized chaff to the sodium hydroxide solution to be 1:7, boil and k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com