Asphalt pavement on-site heat recoveryremixer

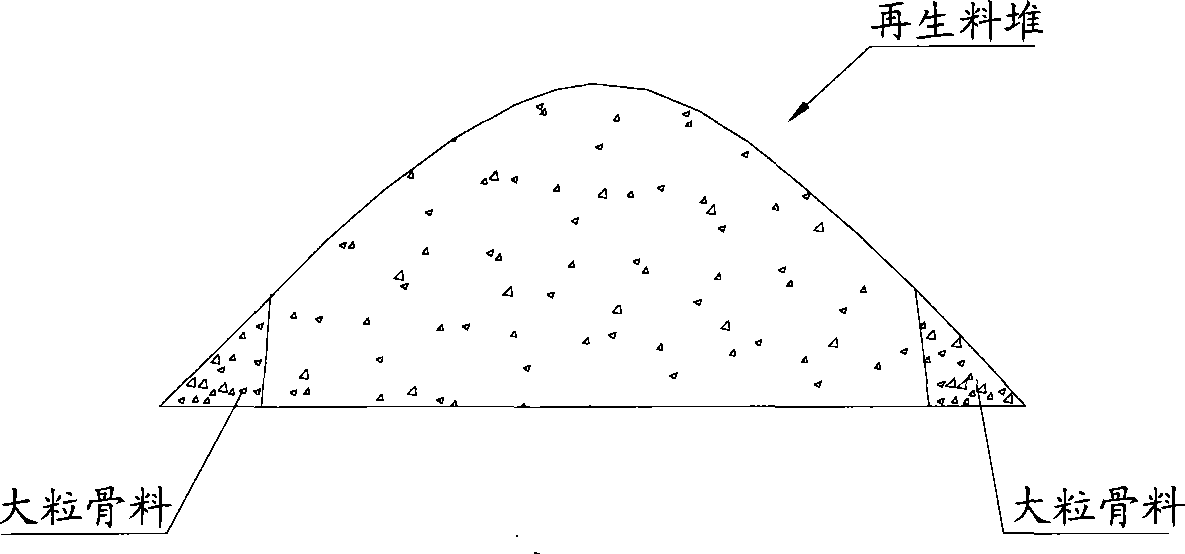

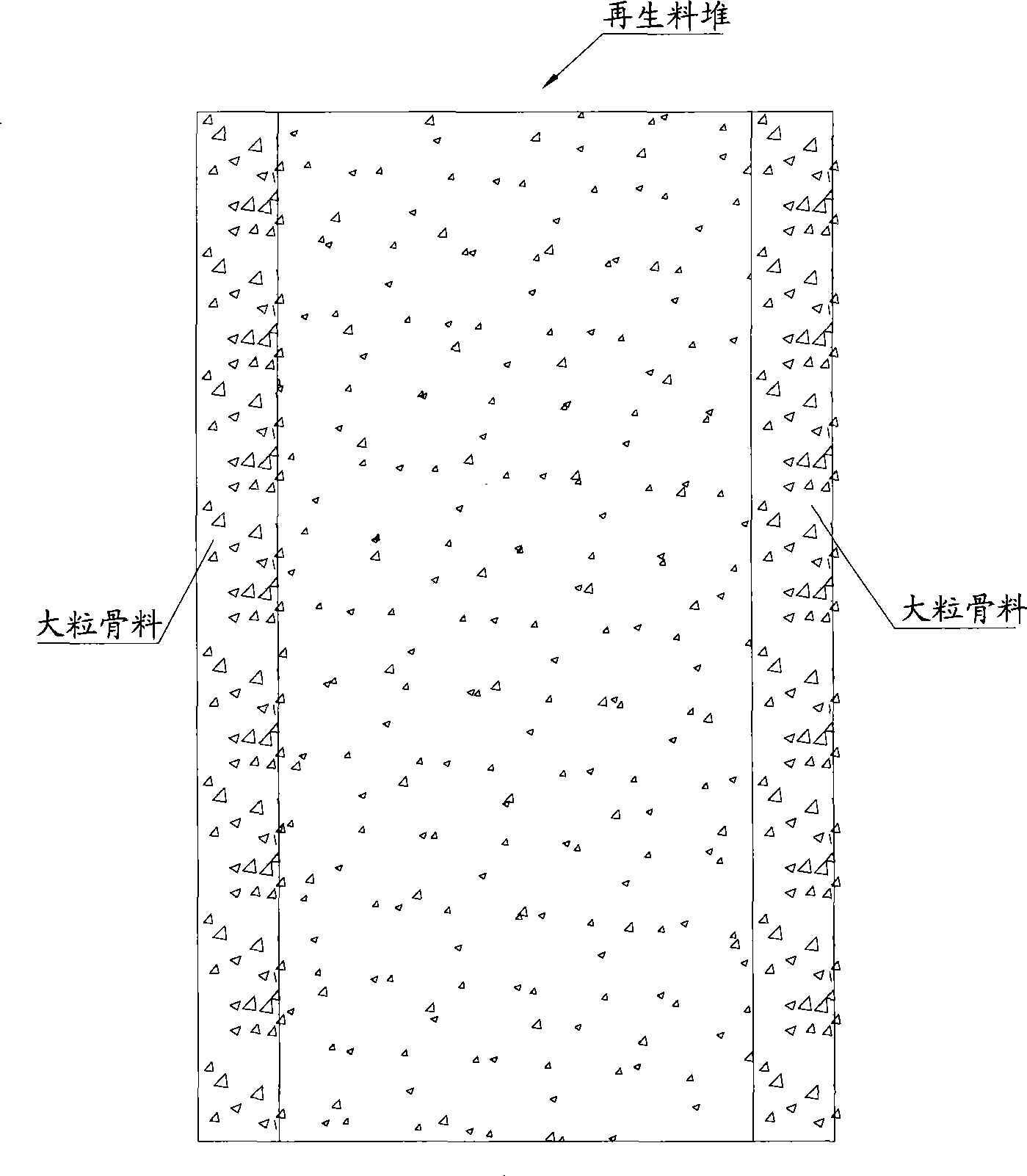

A kind of technology of asphalt pavement and remixing machine, which is applied in the direction of road repair, road, road, etc., and can solve the problems of large particle size aggregate easy to roll to both sides, large void ratio, easy water permeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present embodiment will be described in detail below in conjunction with the accompanying drawings.

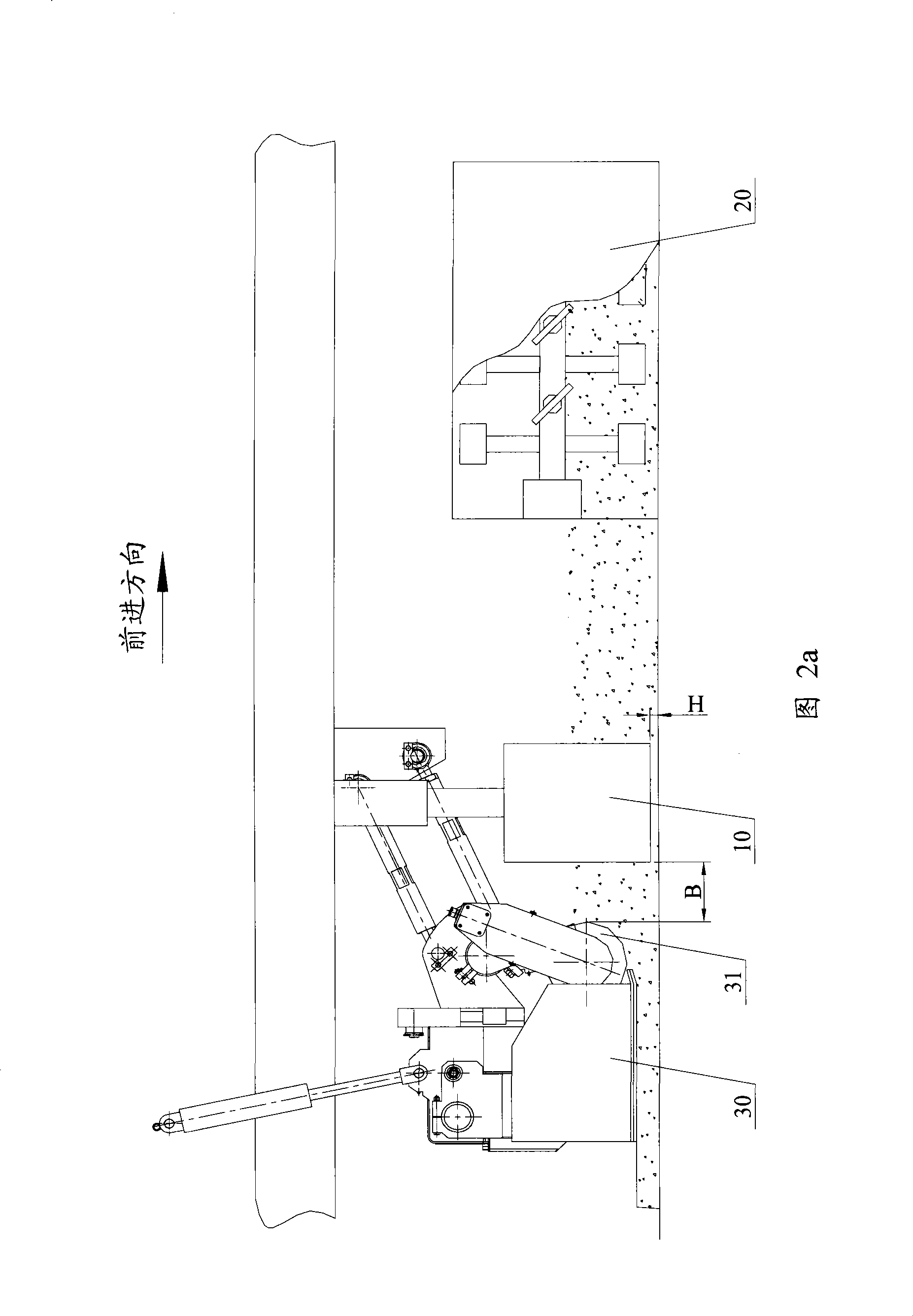

[0039] This embodiment provides an asphalt pavement in-situ hot regeneration remixer, which mainly includes a raking device (not shown in the figure), a stirring device 20, a segregation eliminating device 10 and a paving device 30 arranged in sequence from front to back, The segregation elimination device 10 is arranged between the stirring device 20 and the paving device 30 . Please refer to Fig. 2, wherein Fig. 2a is a partial structural side view of the asphalt pavement hot-in-place recycling remixer of the present invention; Fig. 2b is a partial structural top view of the in-situ asphalt pavement hot-in-place recycling remixer of the present invention.

[0040] It should be noted that the inventive point of the present invention is to eliminate the specific structure of the separating device 10 and its positional relationship. For the sake of clarity, Fig. 2a a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com