Preparation method of silicon dioxide

A silicon dioxide and carbon dioxide technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of too small, uneven particle size distribution, large particle size, etc., to achieve uniform particle size distribution, suitable particle size, reduce The effect of fine powder content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

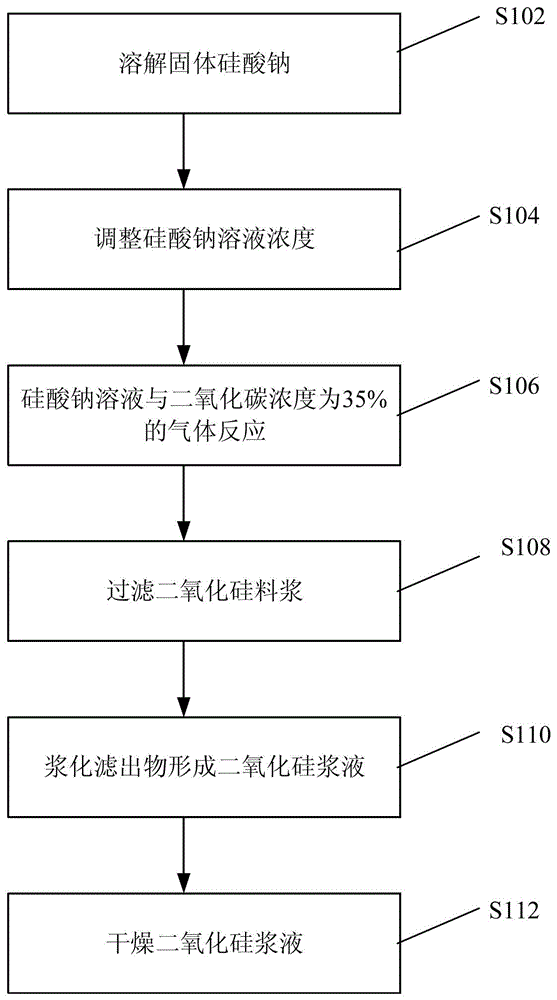

[0029] Embodiment 1: the preparation of silica S1

[0030] 1) Dissolving: such as figure 1 As shown in S102, solid sodium silicate (Anhui Quecheng Silicon Chemical Co., Ltd.: solid-2 type) and water are added to the dissolving static autoclave at a mass ratio of 2:1, and water vapor with a pressure of 0.4Mpa is introduced. Fully dissolve for 1.5 hours, filter out the precipitate with a filter press to obtain a transparent and impurity-free concentrated liquid sodium silicate, and its density (20°C) is 1.1g / cm 3 ;

[0031] Among them, in solid sodium silicate, SiO 2 / Na 2 The weight ratio of O is 3.35;

[0032] 2) Adjustment: such as figure 1 Shown in S104 among, add water in the concentrated liquid sodium silicate obtained by step 1), to adjust wherein Na 2 O nSiO 2 The concentration to 2.20mol / l obtains dilute liquid sodium silicate;

[0033] 3) Synthesis: 3-1) Purify the hot blast stove tail gas into a process gas with a carbon dioxide concentration of 35% (in volume...

Embodiment 2

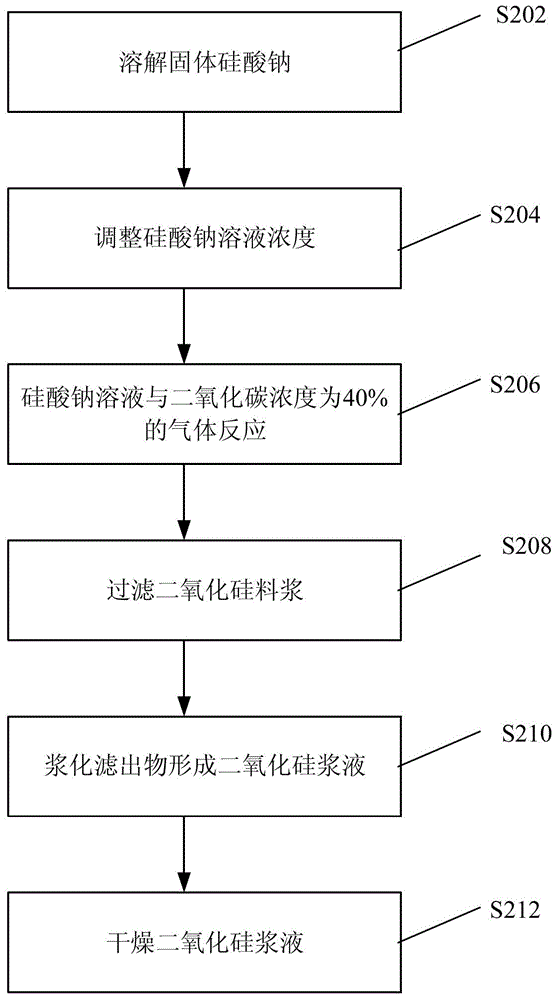

[0043] Embodiment 2: the preparation of silica S2

[0044] 1) Dissolving: such as figure 2 As shown in S202, solid sodium silicate (Anhui Quecheng Silicon Chemical Co., Ltd.: solid-2 type) and water are added to the dissolving static autoclave at a mass ratio of 2:1, and water vapor with a pressure of 0.4Mpa is introduced. Fully dissolve for 2.0 hours, filter out the precipitate with a filter press to obtain a transparent and impurity-free concentrated liquid sodium silicate, and its density (20°C) is 1.3g / cm 3 ;

[0045] Among them, in solid sodium silicate, SiO 2 / Na 2 The weight ratio of O is 3.40;

[0046] 2) Adjustment: such as figure 2 Shown in S204 among, add water in the thick liquid sodium silicate obtained by step 1), to adjust wherein Na 2 O nSiO 2 The concentration to 2.35mol / l obtains dilute liquid sodium silicate;

[0047] 3) Synthesis: 3-1) Purify the hot blast stove tail gas into a process gas with a carbon dioxide concentration of 40% (by volume perc...

Embodiment 3

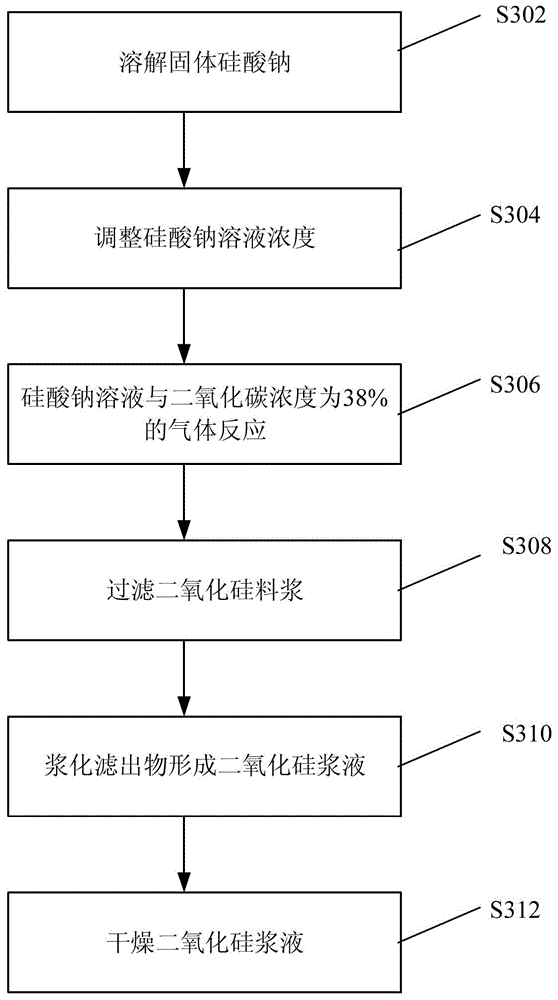

[0057] Embodiment 3: the preparation of silica S3

[0058] 1) Dissolving: such as image 3 As shown in S302, solid sodium silicate (Anhui Quecheng Silicon Chemical Co., Ltd.: solid-2 type) and water are added to the dissolving static autoclave at a mass ratio of 2:1, and water vapor with a pressure of 0.4Mpa is introduced. Fully dissolve for 2.2 hours, filter out the precipitate with a filter press to obtain a transparent and impurity-free concentrated liquid sodium silicate, and its density (20°C) is 1.2g / cm 3 ;

[0059] Among them, in solid sodium silicate, SiO 2 / Na 2 The weight ratio of O is 3.34;

[0060] 2) Adjustment: such as image 3 Shown in S304 among, add water in the concentrated liquid sodium silicate obtained by step 1), to adjust wherein Na 2 O nSiO 2 The concentration to 2.37mol / l obtains dilute liquid sodium silicate;

[0061] 3) Synthesis: 3-1) Purify the hot blast stove tail gas into a process gas with a carbon dioxide concentration of 38% (by volume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com