Precast side fascia with decorative concrete surface layer and manufacturing method thereof

A technology of composite exterior wall board and concrete surface layer, which is applied in the direction of building structure, building components, construction, etc., can solve the problems of difficulty in making wall boards, difficulty in placing insulation layers, and high cost, and achieve good heat insulation effects, The effect of increased firmness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

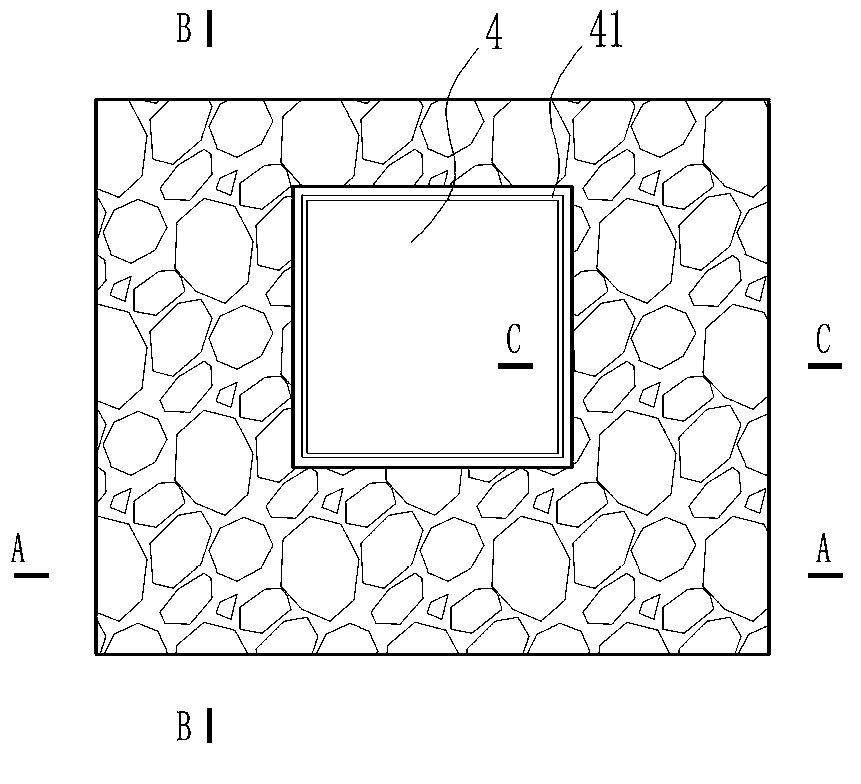

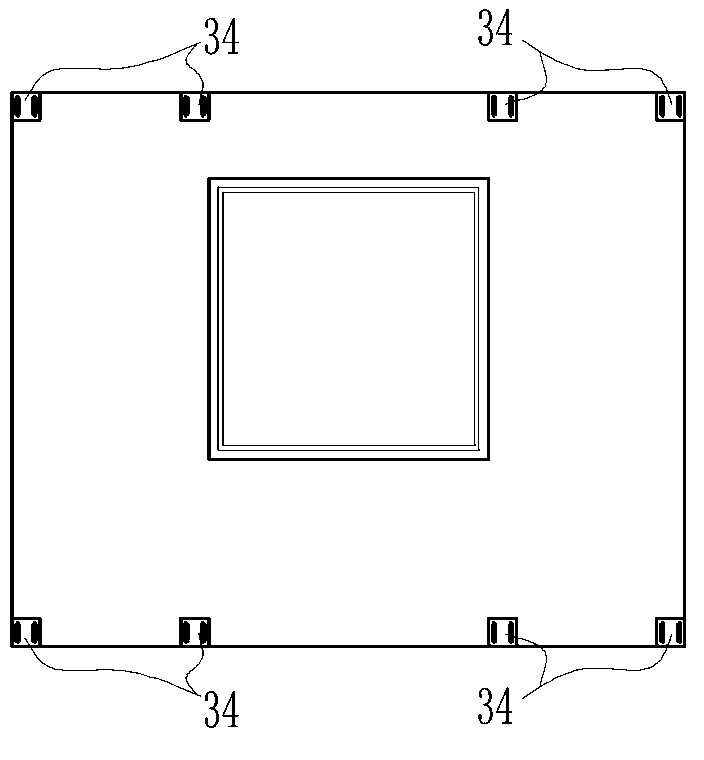

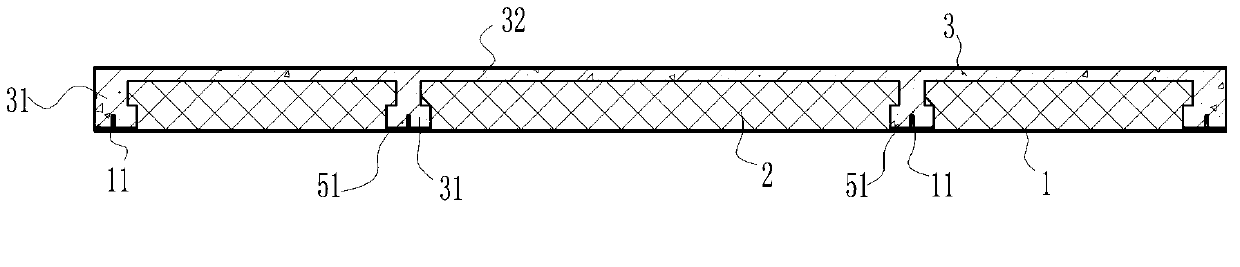

[0045] see Figure 1 to Figure 6 , a prefabricated composite exterior wall panel with a decorative concrete surface layer provided in the present invention includes an inner cement fiber board 1, a sandwich insulation layer 2 and a ribbed outer concrete board 3, and the ribbed outer concrete board 3 includes reinforcement Ribs 31 and panels 32 , the outer surface of the panels 32 is a textured colored concrete surface, and the sandwich insulation layer 2 is filled between the reinforcing ribs 31 . The invention provides a prefabricated composite exterior wall panel, wherein the sandwich insulation layer 2 is a block structure, which not only plays the role of heat preservation, but also can effectively reduce the weight, and is convenient for transportation and installation of the exterior wall panel. The outer surface of the panel 32 is provided with a colored concrete surface layer, which has a better decorative effect and does not need to add an additional decorative layer....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com