Fair-faced structure decorative concrete and preparation method thereof

A decorative and concrete technology, applied in the field of clear water structure decorative concrete and its preparation, to achieve the effect of reducing work intensity, reducing construction connection and installation difficulty, and reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In addition, a preparation method of the clear-water structure decorative concrete comprises the following steps;

[0036] ①Prepare the gelling material of formula quantity, stir evenly for later use; weigh the admixture of formula quantity and add it to water, stir evenly for later use;

[0037] ② Weigh the aggregate and alkali-resistant glass fiber of the formula and mix evenly for later use;

[0038] ③Put 80% of the total mass of the spare cementitious material, aggregate, alkali-resistant glass fiber mixture, and admixture aqueous solution into the mixer, and stir for 5 minutes to obtain a mixed base material;

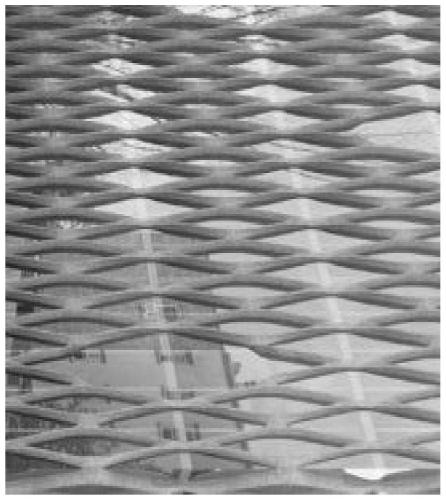

[0039] ④ Disperse the alkali-resistant high-modulus polyethylene fiber and add it to the mixed base material evenly, then add the remaining admixture aqueous solution, and continue stirring for 3 minutes to obtain a clear-water structure decorative concrete. The prepared clear-water structure decorative concrete adopts the 3D printing construction method or...

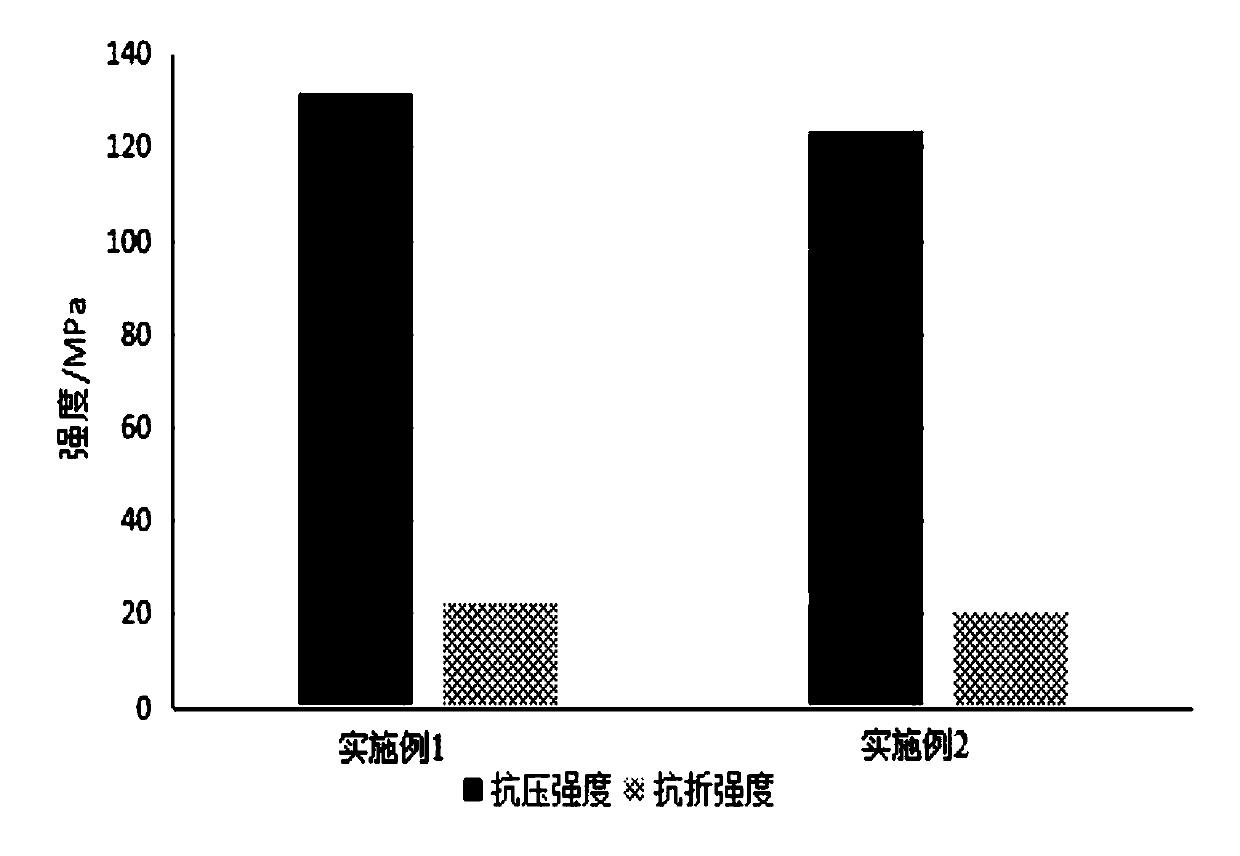

Embodiment 1

[0042] A clear water structure decorative concrete comprises the following raw materials in parts by mass: 1 part of cementitious material, 1.23 parts of aggregate, 0.025 part of fiber, 0.0115 part of admixture and 0.23 part of water.

[0043] As an improvement, the cementitious material is composed of 0.6 part of cement, 0.15 part of active admixture, 0.18 part of superfine metakaolin and 0.07 part of silicon powder in terms of weight percentage.

[0044]Among them, the cement is 42.5 grade Portland cement that meets the requirements of GB 175;

[0045] Active admixture, active SiO 2 Content ≥ 80%, 7d and 28d activity index not less than 80% and 90% respectively, specific surface area ≥ 420m 2 / kg;

[0046] Ultrafine metakaolin, specific surface area 20500m 2 / kg, activity index ≥ 121;

[0047] Silica fume, 28d activity index 91%, specific surface area 15800m 2 / kg, SiO 2 Content 93%, water demand ratio 93%;

[0048] Among them, the aggregate is composed of river sand ...

Embodiment 2

[0060] A clear water structure decorative concrete comprises the following raw materials in parts by weight: 1 part of cementitious material, 1.12 parts of aggregate, 0.031 part of fiber, 0.0113 part of admixture and 0.25 part of water.

[0061] As an improvement, the cementitious material is composed of 0.55 part of cement, 0.16 part of active admixture, 0.21 part of superfine metakaolin and 0.08 part of silicon powder in terms of weight percentage.

[0062] Among them, the cement is 52.5-grade ordinary Portland cement that meets the requirements of GB 175;

[0063] Active admixture, active SiO 2 Content ≥ 80%, 7d and 28d activity index not less than 80% and 90% respectively, specific surface area ≥ 420m 2 / kg;

[0064] Ultrafine metakaolin, specific surface area 20500m 2 / kg, activity index ≥ 121;

[0065] Silica fume, 28d activity index 91%, specific surface area 15800m 2 / kg, SiO 2 Content 93%, water demand ratio 93%;

[0066] Among them, the aggregate is composed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com