Cyanide-free gold nickel alloy plating electroplate liquid

A cyanide-free gold plating and nickel alloy technology, applied in the field of gold-nickel alloy liquid, can solve the problems of high toxicity, high cost, unstable cyanide-free gold-nickel alloy liquid, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] When using the following cyanide-free gold-plated nickel alloy electroplating solution for electroplating, select the copper electrode as the cathode and the carbon plate as the anode. Adjust the temperature to a predetermined value at a current density of 1A / dm 2 ~5A / dm 2 Under plating.

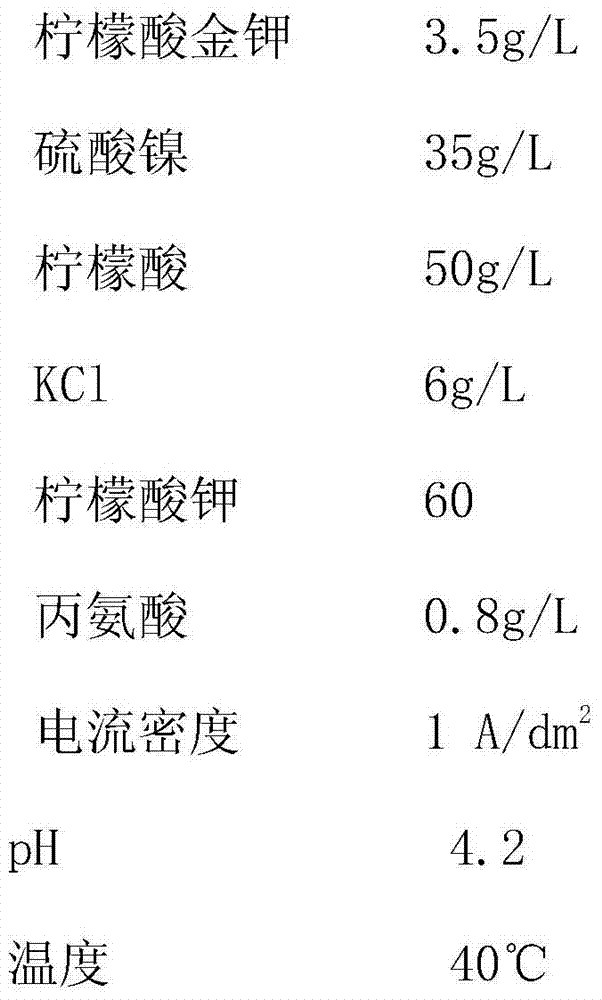

[0022] The composition of the gold-plated nickel alloy electroplating solution is as follows:

[0023]

[0024] According to the electroplating step in the specific embodiment, the electroplating operation is performed using the cyanide-free gold-plated nickel alloy electroplating solution. Results The copper electrode was plated with gold-nickel alloy, and the weight percentage of gold was 95.83% (23K gold) through analysis and test.

Embodiment 2

[0026] When using the following cyanide-free gold-plated nickel alloy electroplating solution for electroplating, select the copper electrode as the cathode and the carbon plate as the anode. Adjust the temperature to a predetermined value at a current density of 1A / dm 2 ~5A / dm 2 Under plating.

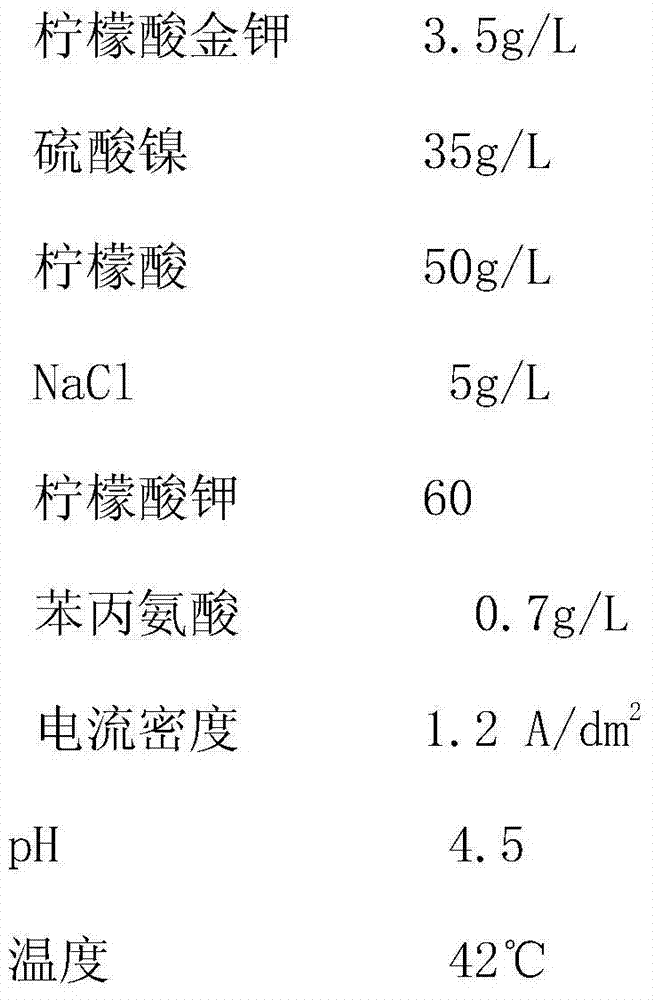

[0027] The composition of the gold-plated nickel alloy electroplating solution is as follows:

[0028]

[0029] According to the electroplating step in the specific embodiment, the electroplating operation is performed using the cyanide-free gold-plated nickel alloy electroplating solution. Results The copper electrode was plated with gold-nickel alloy, and the weight percentage of gold was 95.83% (23K gold) through analysis and test.

Embodiment 3

[0031] When using the following cyanide-free gold-plated nickel alloy electroplating solution for electroplating, select the copper electrode as the cathode and the carbon plate as the anode. Adjust the temperature to a predetermined value at a current density of 1A / dm 2 ~5A / dm 2 Under plating.

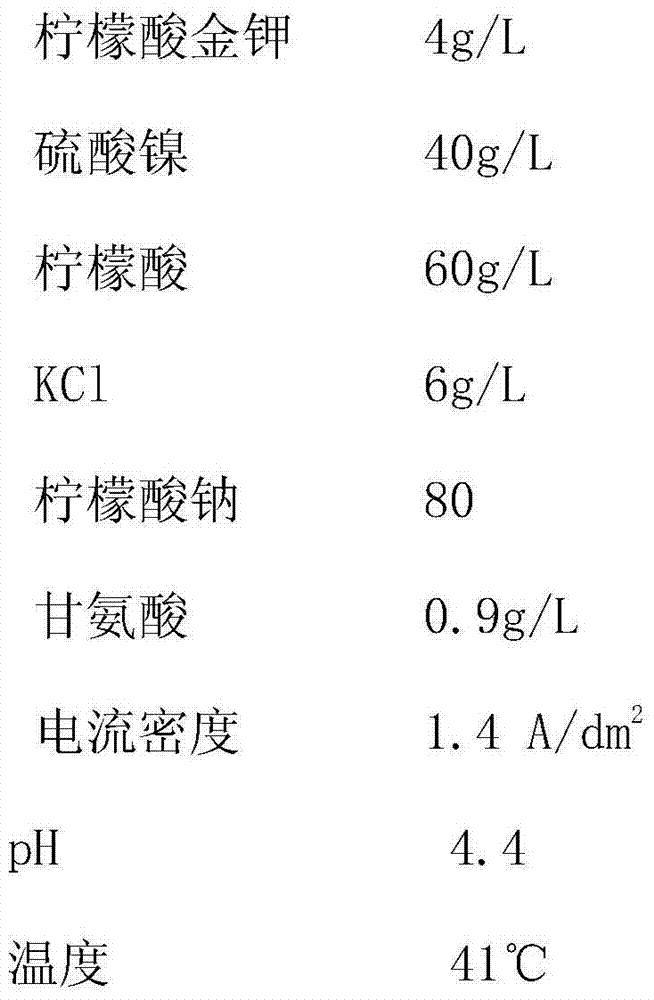

[0032] The composition of the gold-plated nickel alloy electroplating solution is as follows:

[0033]

[0034] According to the electroplating step in the specific embodiment, the electroplating operation is performed using the cyanide-free gold-plated nickel alloy electroplating solution. Results The copper electrode was plated with gold-nickel alloy, and the weight percentage of gold was 95.83% (23K gold) through analysis and test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com