Combination method for structure and function integrated concrete

A combination method and high-performance concrete technology, applied in the direction of building materials, can solve the problems of unfavorable structural overall performance, material waste, etc., and achieve the effect of overcoming compatibility problems, good integrity, and meeting multi-performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

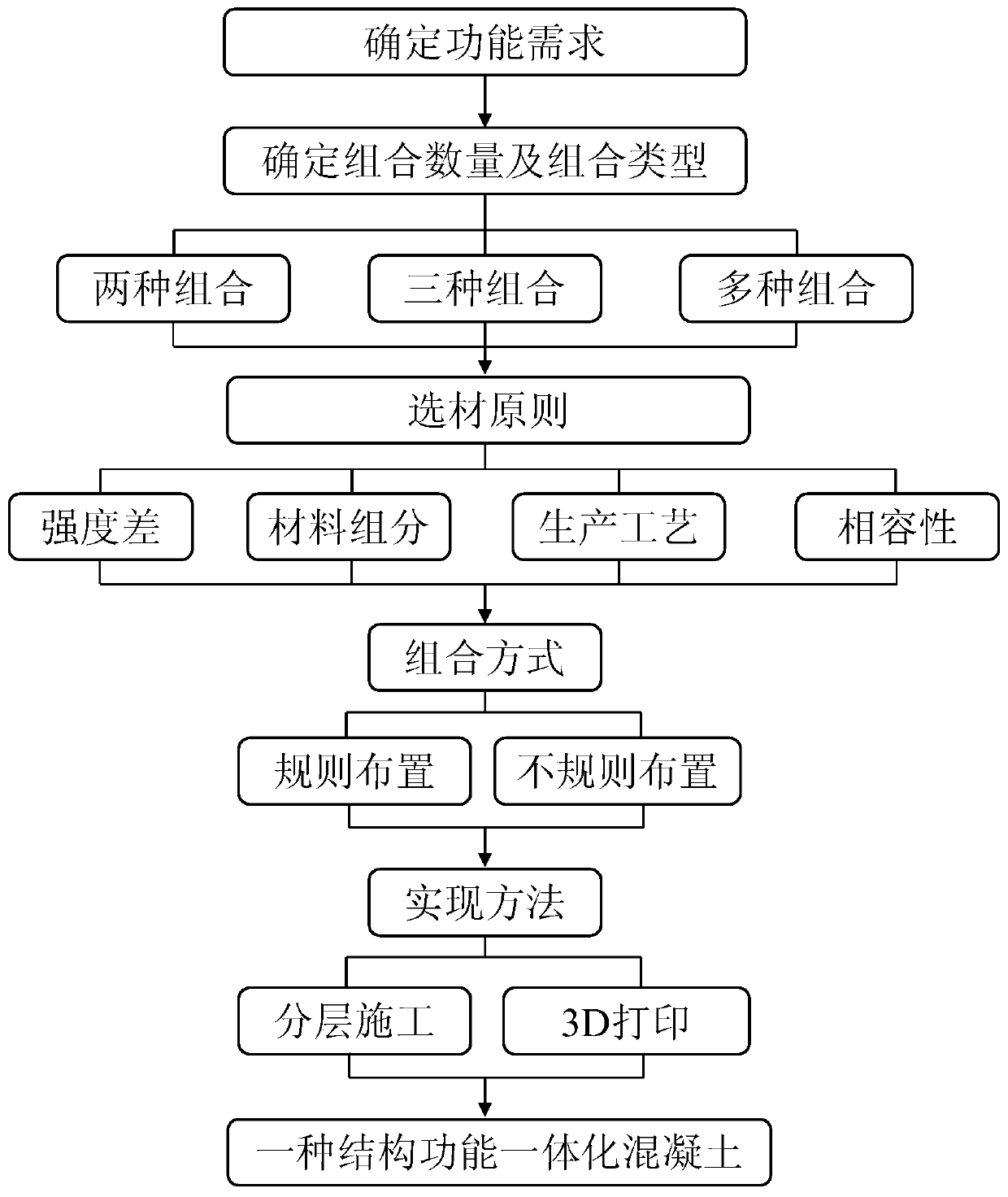

[0083] Such as process figure 1 As shown, the type of single concrete that constitutes the structural-functional integrated concrete is determined according to the functional requirements.

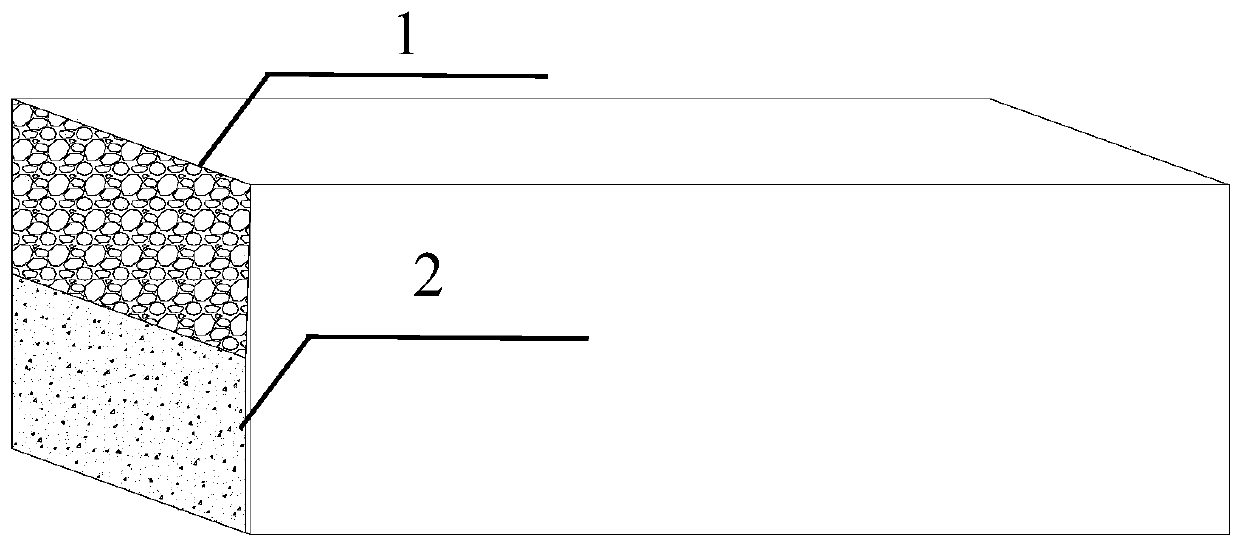

[0084] Select two single concretes for combination, which are respectively set as single concrete A and single concrete B. Among them, single concrete A is load-bearing concrete, specifically ordinary concrete, and its basic components are: natural coarse aggregate, sand, cement, water, and admixtures. Single concrete B is load-bearing concrete, specifically recycled concrete, and its basic components are: recycled coarse aggregate, recycled sand powder, cement, water, and admixtures. The compressive strength difference maintained between the two single concretes is ≤30MPa. The natural coarse aggregate and sand in the raw material components of monomeric concrete A are different from the recycled coarse aggregate and recycled sand powder in the raw material components of monomeric concre...

Embodiment 2

[0089] Such as process figure 1 As shown, the type of single concrete that constitutes the structural-functional integrated concrete is determined according to the functional requirements.

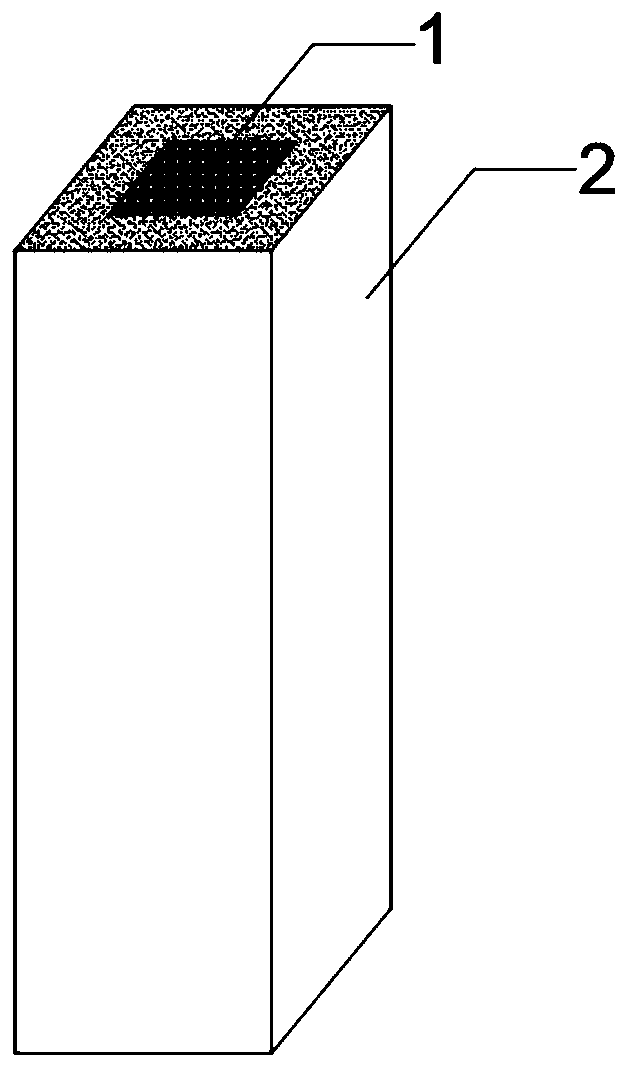

[0090] Select two single concretes for combination, which are respectively set as single concrete C and single concrete D. Among them, single concrete C is load-bearing concrete, specifically fiber concrete, and its basic components are: fiber, natural aggregate, sand, cement, water, and admixture. Monolithic concrete D is functional concrete, specifically thermal insulation concrete, mainly foam concrete with thermal insulation function, and its basic components are: foam material, natural coarse aggregate, sand, cement, water, and admixture. The compressive strength difference maintained between the two single concretes is ≤50MPa. The fiber and natural aggregate in the raw material component of monomeric concrete C are different from the foam material and natural coarse aggregate in th...

Embodiment 3

[0096] Such as process figure 1 As shown, the type of single concrete that constitutes the structural-functional integrated concrete is determined according to the functional requirements.

[0097] Select three single concretes for combination, which are respectively set as single concrete E, single concrete F and single concrete G. Among them, single concrete E is load-bearing concrete, specifically fiber concrete, and its basic components are: fiber, natural coarse aggregate, sand, cement, water, and admixture. Single concrete F is functional concrete, specifically thermal insulation concrete, mainly foam concrete with heat insulation function, and its basic components are: foam material, natural coarse aggregate, sand, cement, water, and admixture. Single concrete G is functional concrete, specifically waterproof concrete, mainly air-entrained concrete, and its basic components are: natural aggregate, sand, cement, air-entraining agent, water, and admixtures. The compress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com