Ejection cushion block structure of injection mould

An injection mold and ejection technology, which is applied in the field of ejector block structure, can solve the problems of unbalanced ejection of the mold, warping and deformation of the ejector plate, and inability to release the mold smoothly, and achieves a simple manufacturing process, stable and reliable work, and satisfactory Effects of structural and cosmetic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

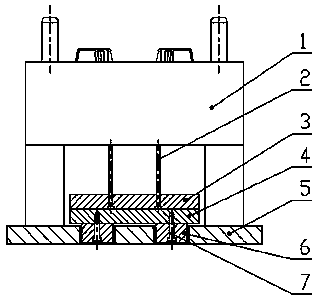

[0010] Depend on figure 1 It is known that an ejector block structure of an injection mold is composed of a movable template 1, an ejector pin 2, an ejector plate 3, an ejector plate 4, a foot doubler plate 5, an ejector block 6, and fixing screws 7. There is an thimble 2 under the moving template 1, and the thimble 2 is fixed on the thimble plate 3, and the thimble panel 4 is fixed on the mold foot doubler 5, and the feature is that the mold foot doubler 5 is also provided with an ejection pad 6 , The ejector block 6 and the thimble panel 4 are connected by screws 7 . The diameter and height of the ejection pad 6 and the thimble panel 4 are consistent, which facilitates the replacement of the ejection pad 6 .

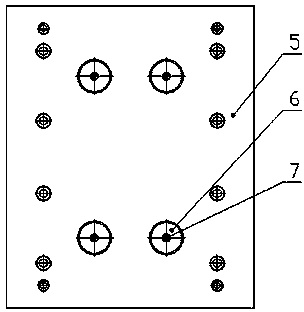

[0011] Depend on figure 2 It is known that it is a top view of the mold foot compound board. The mold foot doubler plate 5 is provided with four through holes for installing ejection pads 6 , and the mold foot doubler plate 5 ejects the pads 6 and is fixed with fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com