Supporting system for multilayer continuous support of fabricated building outer wall

A technology of building exterior walls and support systems, which is applied in the direction of construction, building structure, and housing structure support, etc. It can solve the problems of laborious replacement of universal wheels, troublesome fixing, and affecting the service life of bearings, and achieves convenient installation and adjustment. Assembly, rust reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

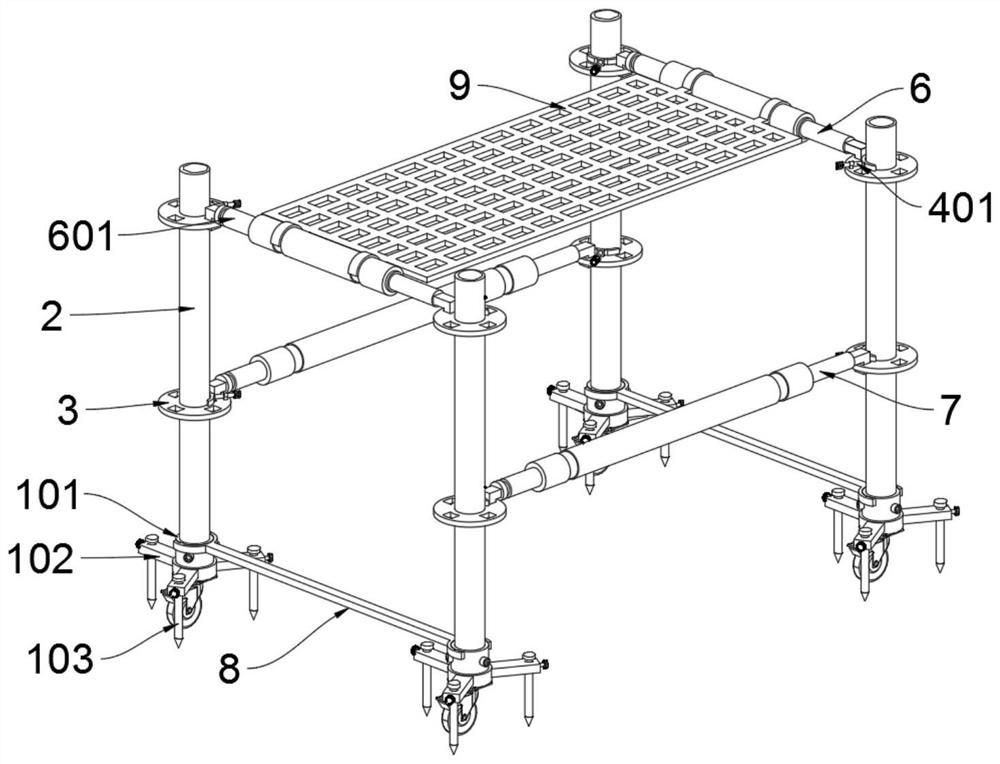

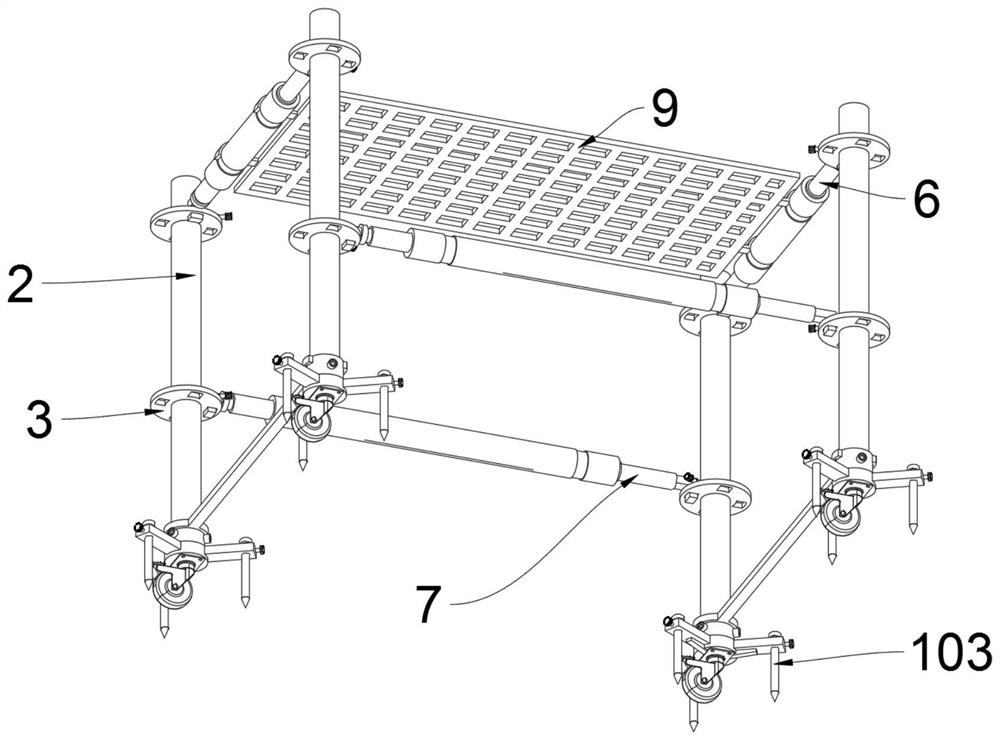

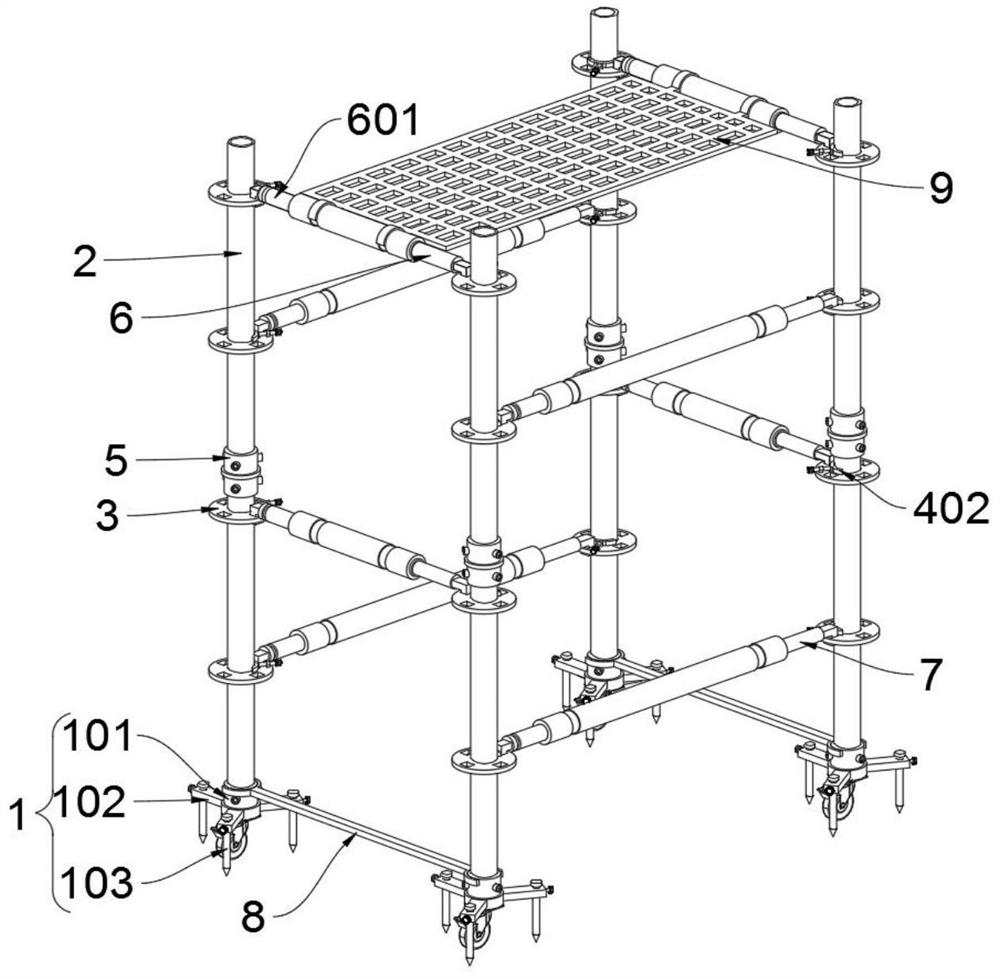

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035]The present invention provides a support system for the multi-layer continuous support of the exterior wall of a prefabricated building, including a support mechanism 1; the support mechanism 1 has four components, and a universal wheel is installed on the bottom of the support mechanism 1; the support mechanism 1 is fixed by bolts A steel pipe 2, and the other end of the steel pipe 2 is fixedly connected to the connecting sleeve B5; a support rod 9 is installed between the two support mechanisms 1, and the support rod 9 consists of two parts; a sliding connection is installed on the steel pipe 2 A connecting plate 3, and a clamping mechanism 4 is installed on the connecting plate 3, a support plate 8 is installed between two relatively positive connecting plates 3; a connecting rod A6 and a connecting rod B7 are installed between two steel pipes 2 , and the connecting rod A6 and the connecting rod B7 have the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com