3D printing building structure material and use method thereof

A building structure and 3D printing technology, applied in the field of 3D printing, can solve the problems of poor adhesion and crack resistance of printing materials, not satisfying the development concept of material reduction and recycling, and low strength of structural buildings, so as to save raw materials , mild conditions, high adhesion and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

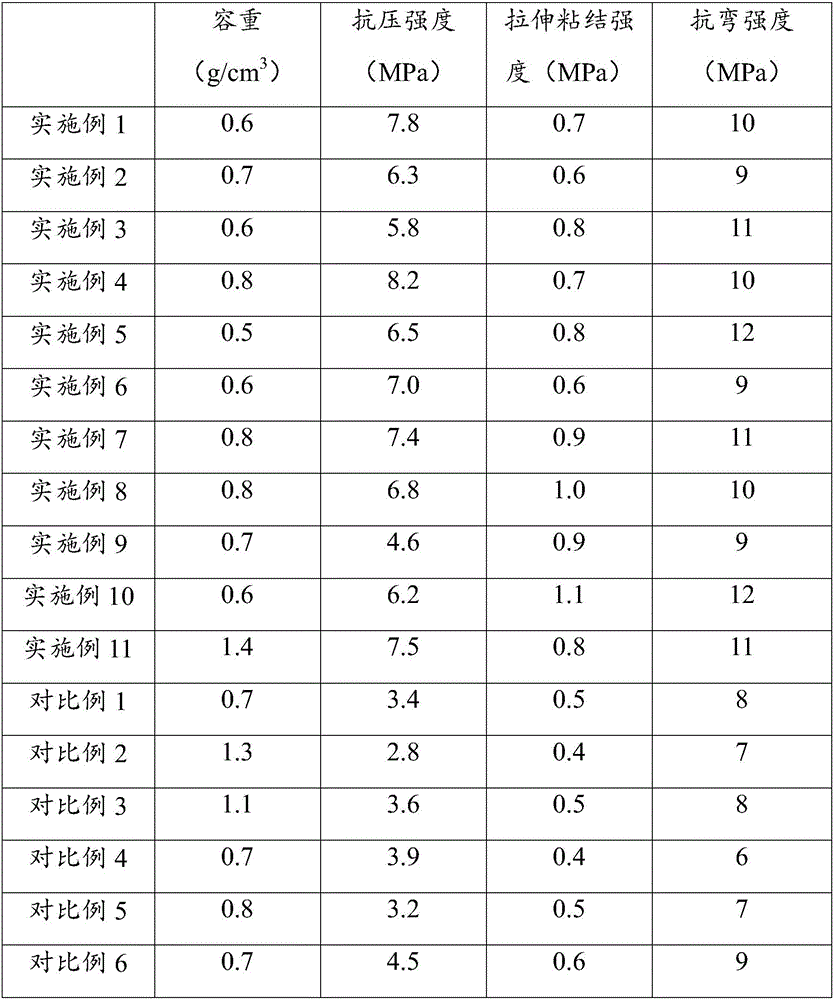

Examples

Embodiment 1

[0079] A method for preparing a 3D printing building structure material, comprising the following steps:

[0080] (1) crushing, ball milling and drying 40 parts by weight of construction waste and 15 parts by weight of domestic waste after disinfection and deodorization to obtain construction waste powder and domestic waste powder;

[0081] (2) Put the construction waste powder and domestic waste powder obtained in step (1) into a blender, add 5 parts by weight of polyphenylene particles, 10 parts by weight of rubber powder, 10 parts by weight of desulfurized gypsum, and 10 parts by weight of powder Mix coal ash evenly;

[0082] (3) Add 30 parts by weight of water into the mixer and stir until viscous slurry state;

[0083] (4) Disperse 8 parts by weight of glass fibers into the slurry and continue to stir evenly to obtain a 3D printed building structure material.

Embodiment 2

[0085] A method for preparing a 3D printing building structure material, comprising the following steps:

[0086] (1) crushing, ball milling and drying 70 parts by weight of construction waste and 10 parts by weight of domestic waste after disinfection and deodorization to obtain construction waste powder and domestic waste powder;

[0087] (2) The construction waste powder and domestic waste powder obtained in step (1) are put into a blender, add ceramsite of 20 parts by weight, rubber powder of 5 parts by weight, desulfurized gypsum of 20 parts by weight, natural stone powder of 12 parts by weight well mixed;

[0088] (3) Add 40 parts by weight of water into the mixer, and stir to a viscous slurry state;

[0089] (4) Disperse 20 parts by weight of steel fibers into the slurry and continue to stir evenly to obtain a 3D printed building structure material.

Embodiment 3

[0091] A method for preparing a 3D printing building structure material, comprising the following steps:

[0092] (1) crushing, ball milling and drying 50 parts by weight of construction waste and 12 parts by weight of domestic waste after disinfection and deodorization to obtain construction waste powder and domestic waste powder;

[0093] (2) Put the construction waste powder and domestic waste powder obtained in step (1) into a blender, add 10 parts by weight of perlite, 8 parts by weight of rubber powder, 15 parts by weight of desulfurized gypsum, and 11 parts by weight of chemical mineral Mix the powder evenly;

[0094] (3) Add 30 parts by weight of water into the mixer and stir until viscous slurry state;

[0095] (4) Disperse 10 parts by weight of ceramic fibers into the slurry and continue to stir evenly to obtain a 3D printed building structure material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com