High-strength glass decorative steel slag concrete prefabricated art stone and manufacture method thereof

A technology of steel slag concrete and glass, which is applied to the pavement paved with prefabricated blocks, manufacturing tools, ceramic molding machines, etc., can solve the problem of low compressive strength, improve mechanical properties and anti-skid performance, change visual effects, improve Effect of compressive strength and flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

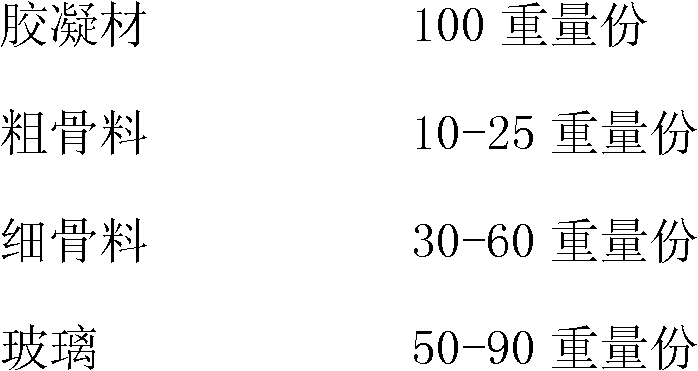

[0058] Base concrete ratio (weight ratio):

[0059] Water: cement: coarse aggregate: fine aggregate = 10%: 40%: 40%: 10%. The cement is ordinary Portland cement with a strength grade of 42.5; the coarse aggregate is stone with a particle size range of 2-6mm; the fine aggregate is fine sand with a particle size range of 0.1-0.5mm.

[0060] Surface concrete ratio (weight ratio):

[0061] Among them: cementitious material = white cement: ordinary Portland cement = 70%: 30%

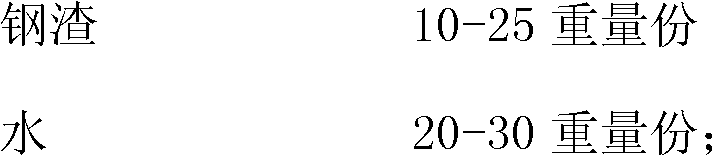

[0062] Table 1 surface layer material formula

[0063]

[0064] The preparation method is as follows:

[0065] Step 1: After measuring the base material and surface material according to the design ratio, add them to the mixing device for uniform mixing.

[0066] The second step: evenly spread the mixed base material in the supported mold, and cover the cover;

[0067] Step 3: Push it into the vacuum equipment to evacuate to below 0.5MPa, 30 seconds to 60 seconds;

[0068] Step 4: Perform vibration a...

Embodiment 6-8

[0080] Base concrete ratio (weight ratio): cement is ordinary portland cement, strength grade is 42.5; coarse aggregate is stone, particle size range is 2-6mm; fine aggregate is fine sand, particle size range is 0.1-0.5 mm.

[0081] Table 3 base material formula

[0082]

[0083] Surface concrete proportioning (weight ratio) is the same as embodiment 1.

[0084] The preparation method is as follows:

[0085] Step 1: After measuring the base material and surface material according to the design ratio, add them to the mixing device for uniform mixing.

[0086] The second step: evenly spread the mixed base material in the supported mold, and cover the cover;

[0087] Step 3: Push it into the vacuum equipment to evacuate to below 0.5MPa, 30 seconds to 60 seconds;

[0088] Step 4: Perform vibration and pressurization for 30 seconds to 90 seconds; among them, the pressure of vibration pressurization is 100KN, the vibration force of vibration is 100KN, and the vibration freque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com