Concrete hollow double-layer floor and construction method thereof

A concrete and double-layer technology, applied in floors, building components, buildings, etc., can solve problems such as difficulty in ensuring the concrete density of the lower floor, limited application range of hollow double-layer floors, affecting the indoor appearance of buildings, etc. Concrete material, shortened construction period, good appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

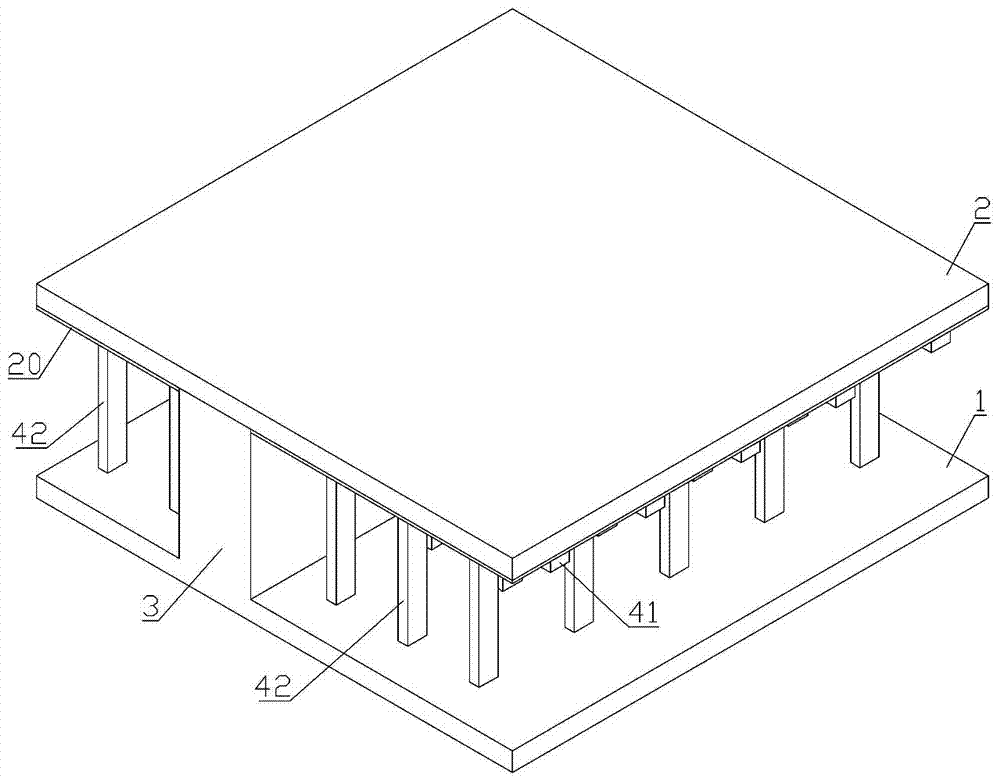

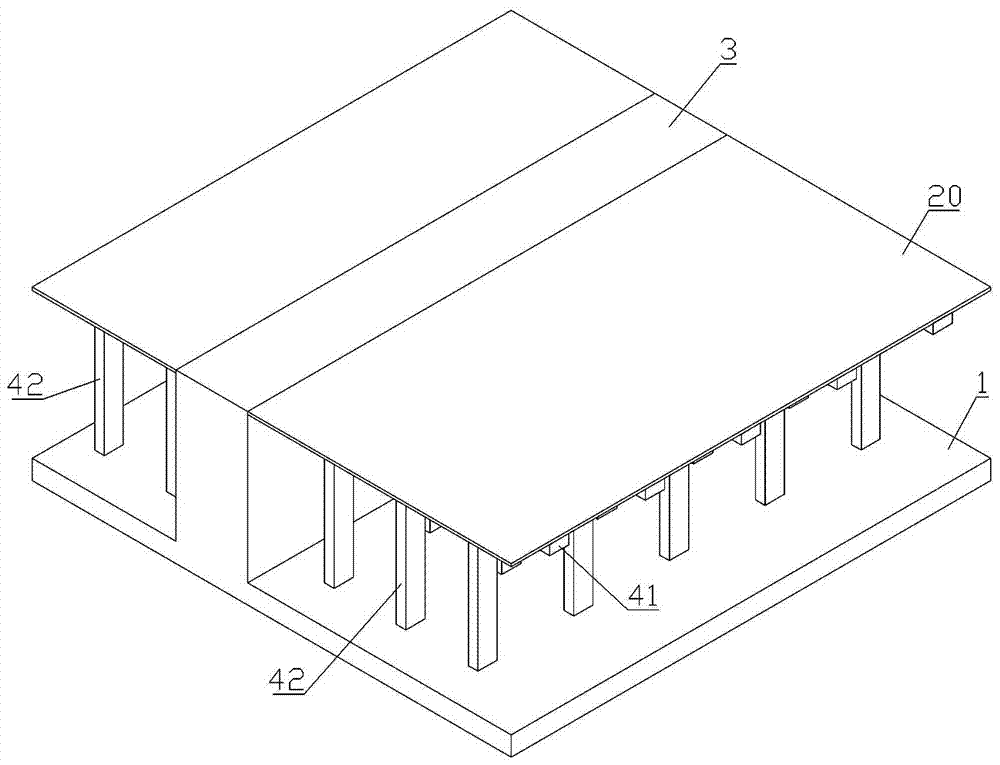

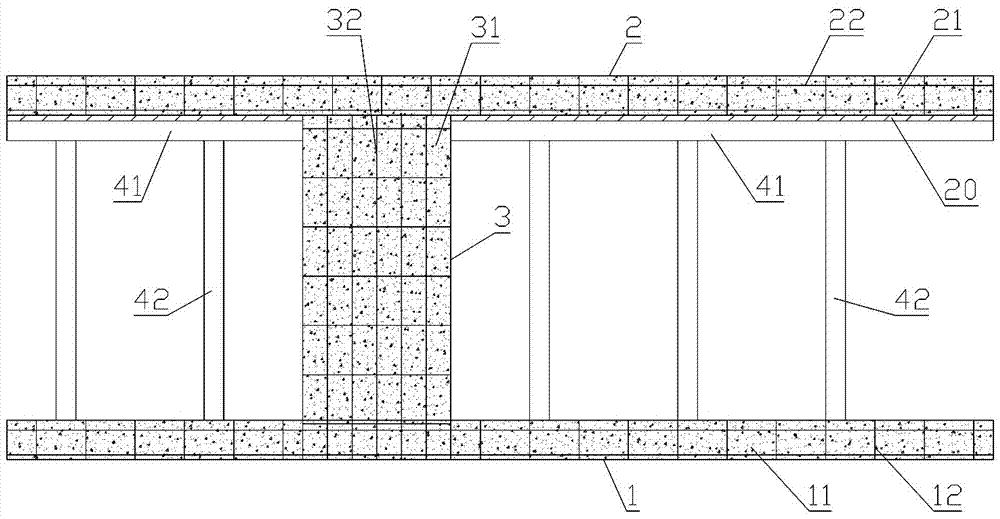

[0052] refer to Figure 1 to Figure 3 A concrete hollow double-layer floor slab comprises a lower slab 1 , an upper slab 2 and a structural beam 3 .

[0053] The lower slab 1 is a reinforced concrete structure, which consists of the lower slab concrete 11 densely covering the lower slab steel bars 12, the upper slab 2 is a reinforced concrete structure, which consists of the upper slab concrete 21 densely covering the upper slab steel bars 22, and the structural beam 3 is The reinforced concrete structure is composed of structural beam concrete 31 densely covering structural beam steel bars 32 .

[0054] The lower plate 1, the upper plate 2 and the structural beam 3 are enclosed to form a mold cavity; the structural beam 3 and the lower plate 1 are integral structures formed continuously, the lower plate steel bar 12 is socketed with the structural beam steel bar 32, and the upper plate 2 is connected On the structural beam 3; there is an upper plate template 20 and a wooden su...

Embodiment 2

[0058] refer to Figure 1 to Figure 10 , a construction method for a concrete hollow double-layer floor slab, the built double-layer floor slab has a lower floor 1, an upper floor 2 and a structural beam 3, and the lower floor 1, the upper floor 2 and the structural beam 3 are enclosed to form a mold cavity, It includes the following construction steps:

[0059] Step 1, build the scaffold support system 5 according to the prior art (such as Figure 4 ).

[0060] Step 2, build the lower layer template 10 (such as Figure 4 );

[0061] The lower slab formwork 10 is composed of several floor slab formworks that are approached and connected in sequence, and the lower slab formwork 10 is supported by the scaffolding support system 5 through the supporting wooden squares 51 .

[0062] Step 3, lifting structural beam reinforcement (such as Figure 5 );

[0063] The prefabricated structural beam reinforcing bar 32 is hoisted on the lower floor formwork 10, the structural beam re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com