Fiber Concrete Sandwich Insulation Decorative Panel

A technology of thermal insulation decorative panels and fiber concrete, applied in covering/lining, construction, building construction, etc., can solve problems such as cracking of facings, easy fires, and aggravated creep of thermal insulation systems, so as to increase integrity and rigidity, The effect of eliminating on-site work processes and improving fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

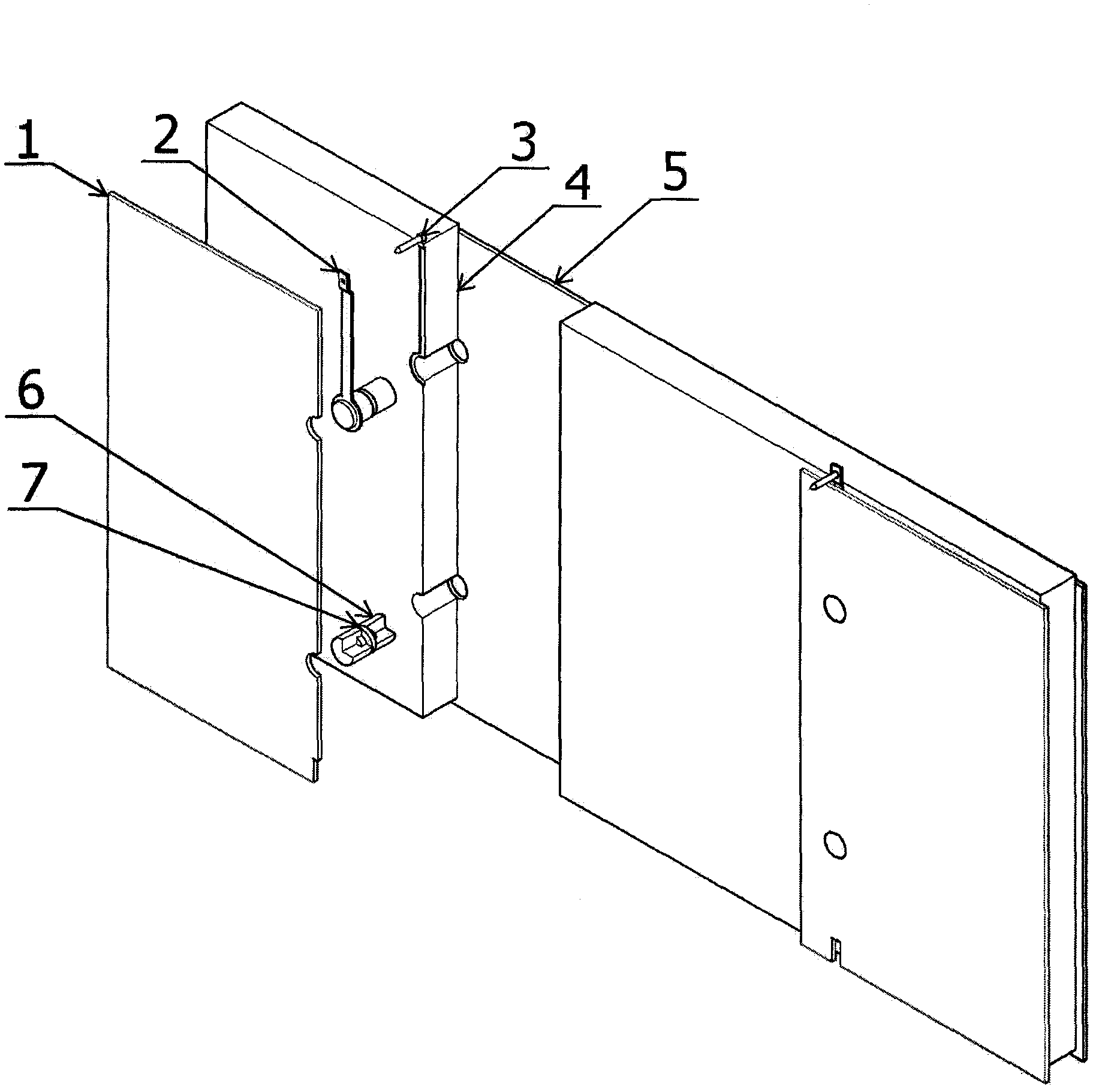

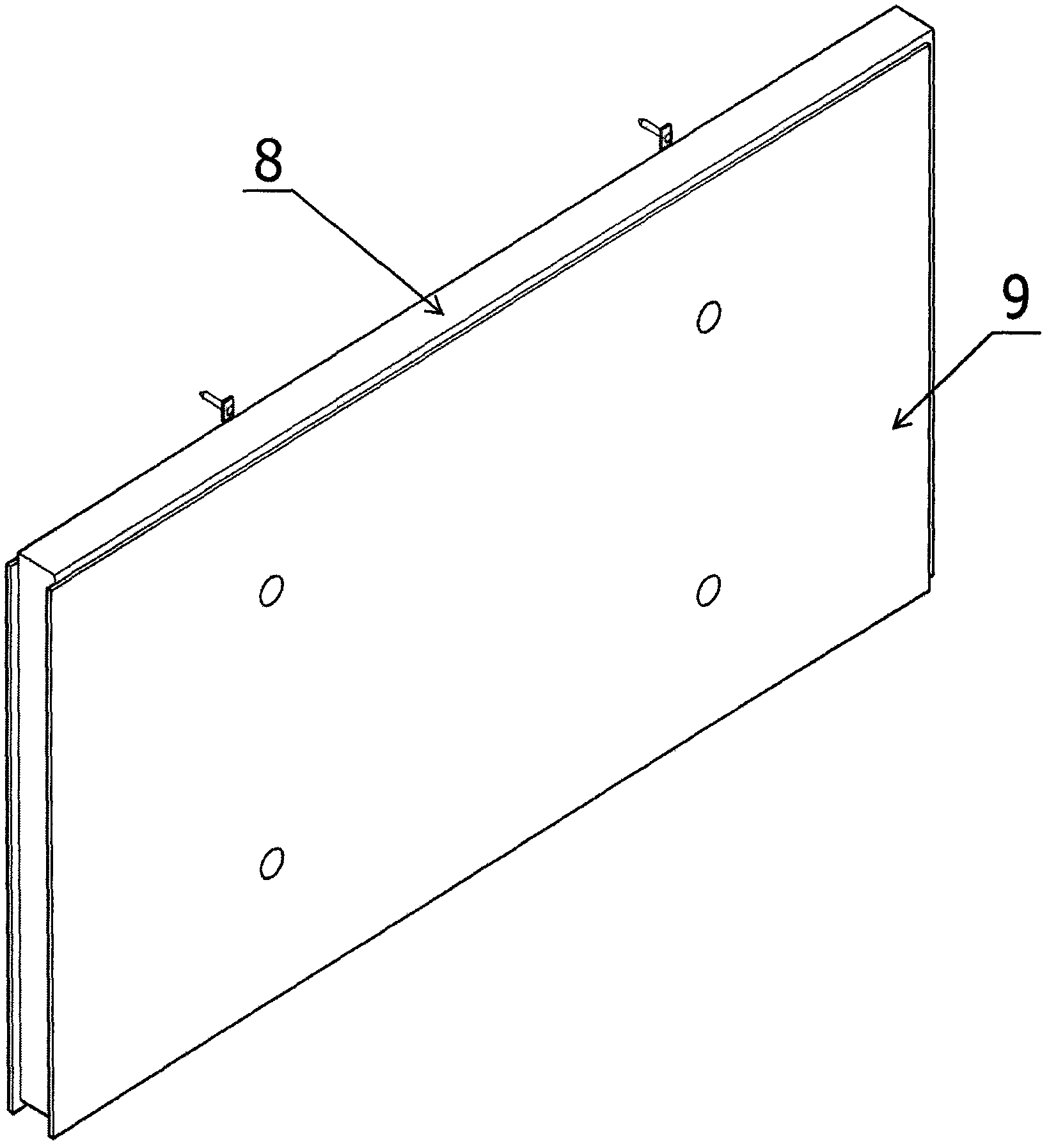

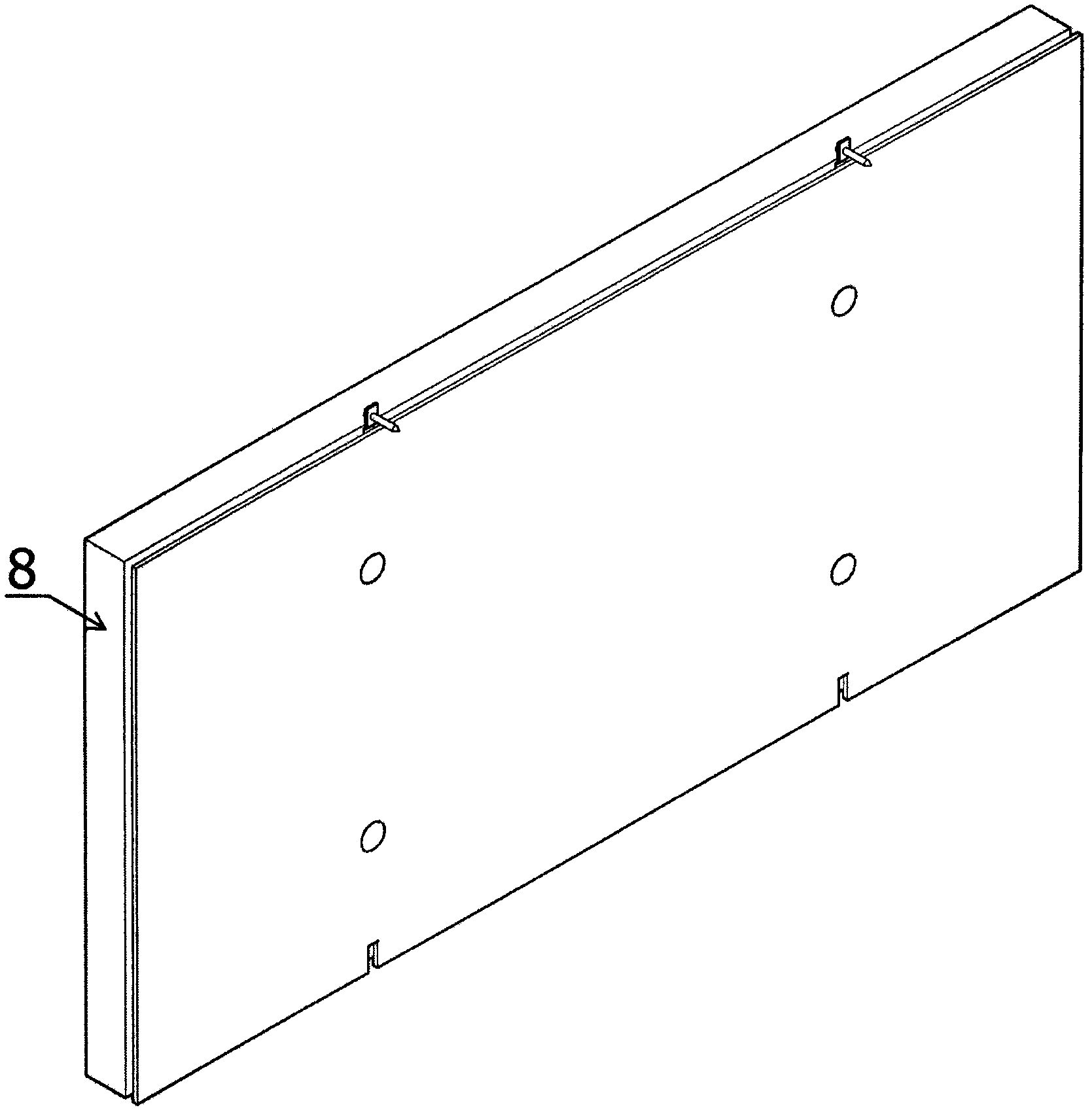

[0014] This embodiment is a fiber concrete thermal insulation decorative board, which is composed of a core board 4, a face plate 5, a back board 1 and the like. its structure see Figure 1-Figure 4 , the panel 5 of the present invention, the thickness of backboard 1 is 5-8mm, on the panel 5 and backboard 1 corresponding machinery opens the conical hole, sandwiches core board 4 between panel 5 and backboard 1, and mechanically opens on core board 4 A round hole, the broken bridge piece 7 passes through the hole and is fixed in the middle of the core plate 4 with an adhesive, and the face plate 5, the back plate 1 and the broken bridge piece 7 are connected by anchor plugs 6 to form a space force structure and a bearing structure. Loads of first line of defense. The face plate 5, the back plate 1 and the core plate 4 are bonded together with an adhesive to form the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com