Decorative pavement product and preparation method thereof

A product and pavement technology, which is applied in the field of decorative pavement products and its preparation, can solve the problem of lack of anti-seepage and easy-clear decorative pavement products, and achieve the effect of rough surface and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

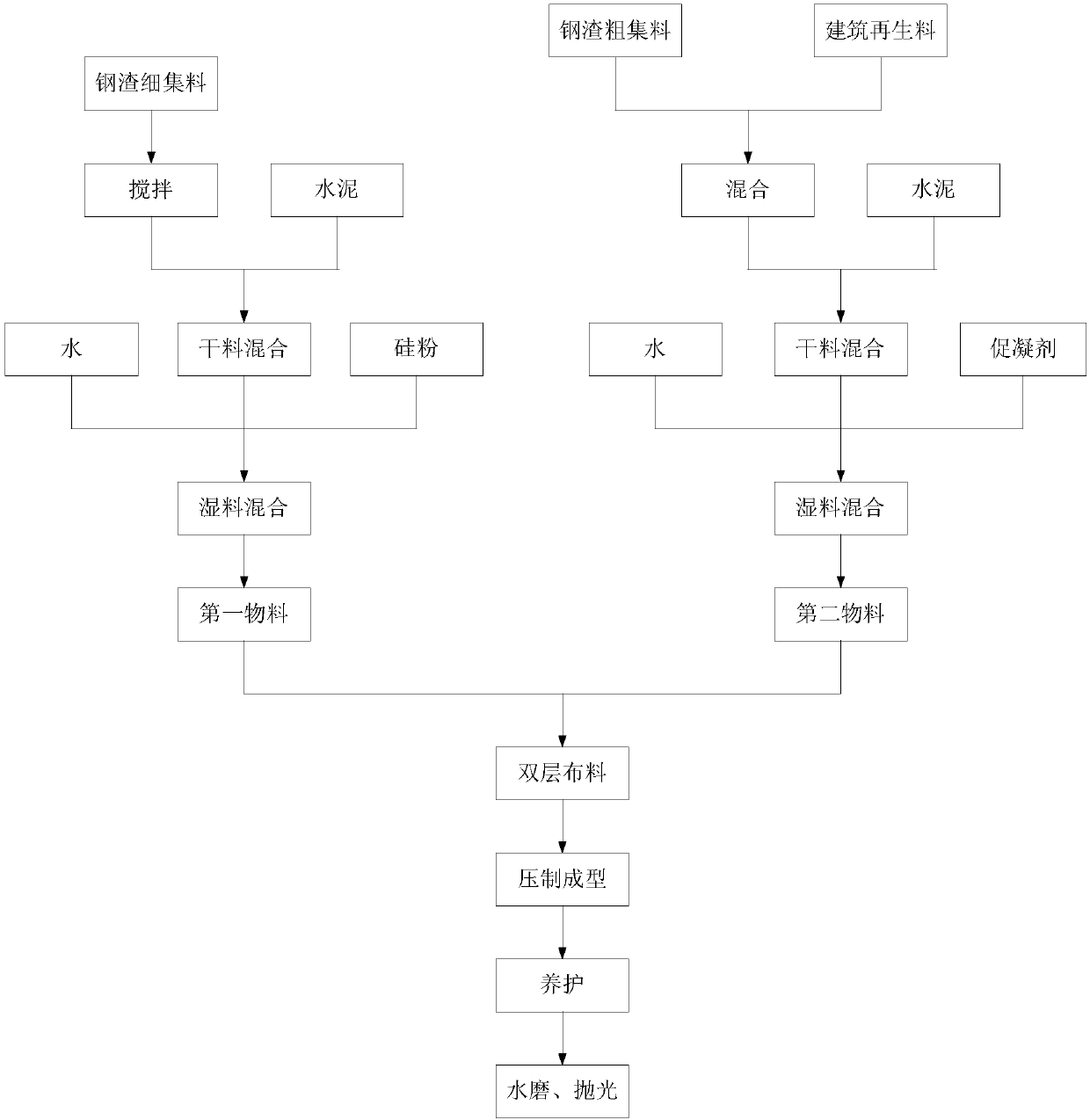

Method used

Image

Examples

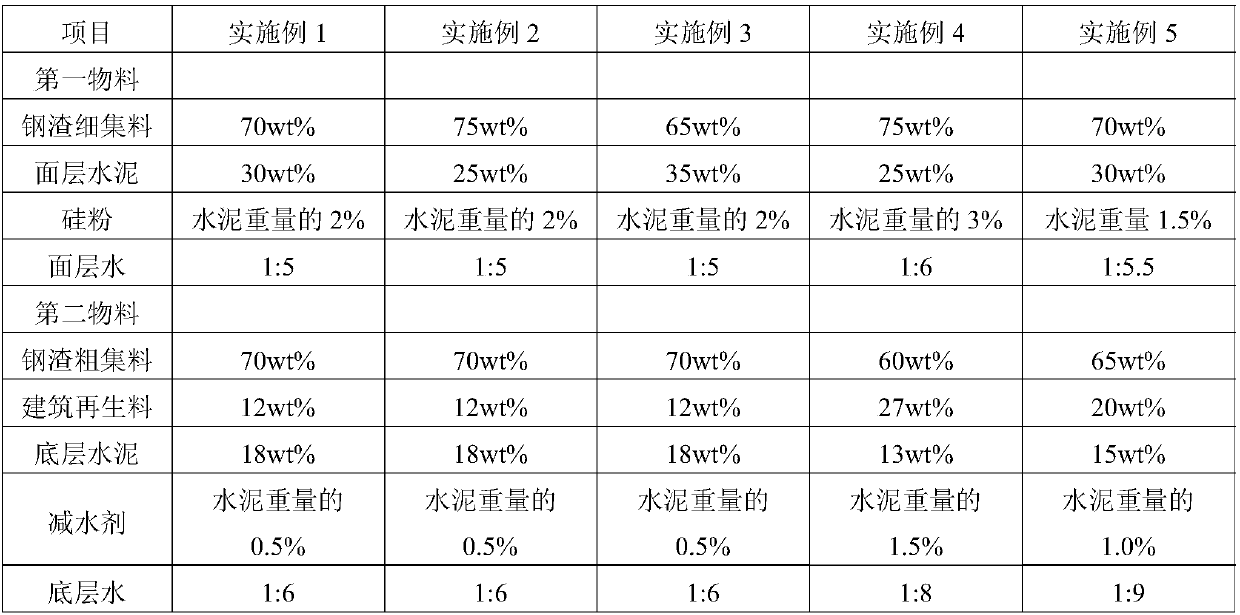

Embodiment 1

[0081] The fabric components are respectively taken by weight percentage: 70wt% of steel slag fine aggregate, 30wt% of surface layer cement, and silicon powder is taken, and the addition amount of silicon powder is 2% of the weight of the surface layer cement. The weight ratio of adding surface layer water to fabric is 1:5. Among them, the steel slag fine aggregate is the steel slag fine aggregate of the electric furnace drum, and the surface layer cement is selected from 52.5 grade ordinary Portland cement or 52.5 grade white Portland cement, and the cement type can be selected according to the color requirements, silica fume The particle size is 0.15-0.20μm, and the specific surface area is 20000m 2 / kg, SiO 2 The content is 89% silica fume, and the surface water is tap water. Stir the steel slag fine aggregate in the mixer for 20 seconds, then add surface cement and mix for 40 seconds, then add water through an automatic water adding device, add water and add silicon powd...

Embodiment 2

[0086] The fabric components are respectively taken by weight percentage: 75wt% of steel slag fine aggregate, 25wt% of surface layer cement, and silicon powder is taken, and the addition amount of silicon powder is 2% of the weight of the surface layer cement. The weight ratio of adding surface layer water to fabric is 1:5. Among them, the steel slag fine aggregate is the steel slag fine aggregate of the electric furnace drum, and the surface layer cement is selected from 52.5 grade ordinary Portland cement or 52.5 grade white Portland cement, and the cement type can be selected according to the color requirements, silica fume The particle size is 0.15-0.20μm, and the specific surface area is 20000m 2 / kg, SiO 2 The content is 89%, and the surface water is tap water. Stir the steel slag fine aggregate in the mixer for 20 seconds, then add surface cement and mix for 40 seconds, then add water through an automatic water adding device, add water and add silicon powder and mix f...

Embodiment 3

[0091] The fabric components are respectively taken by weight percentage: 65wt% of steel slag fine aggregate, 35wt% of surface layer cement, and silicon powder is taken, and the addition amount of silicon powder is 2% of the weight of the surface layer cement. The weight ratio of adding surface layer water to fabric is 1:5. Among them, the steel slag fine aggregate is the steel slag fine aggregate of the electric furnace drum, and the surface layer cement is selected from 52.5 grade ordinary Portland cement or 52.5 grade white Portland cement, and the cement type can be selected according to the color requirements, silica fume The particle size is 0.15-0.20μm, and the specific surface area is 20000m 2 / kg, SiO 2 The content is 89% silica fume, and the surface water is tap water. Stir the steel slag fine aggregate in the mixer for 20 seconds, then add surface cement and mix for 40 seconds, then add water through an automatic water adding device, add water and add silicon powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com