Method for manufacturing decorative concrete product

A technology for decorating concrete and concrete products, which is applied in the direction of manufacturing tools, ceramic molding machines, molds, etc., and can solve the problem that the retarder is prone to diffusion, migration, shape change, retarder migration or shape change, and influence on the fineness of the pattern, etc. problem, to achieve the effect of low production cost, short production cycle and ingenious conception

Active Publication Date: 2018-07-13

HUBEI UNIV OF TECH

View PDF6 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

This technology makes sure there are no cracks or holes where the casted concrete becomes wet during construction due to excessive evaporation from its surface caused by rainwater hitting against the edges of these openings. By adding an absorbant material like calcium chloride (CaCl2) onto this area instead of just drying out over time, any tiny debris will get stuck inside without affecting the strength of the final structure made up entirely of such materials. Additionally, if certain areas have specific shapes they may also become clearer when cleanled afterwards for better appearance quality. Overall, this new technology simplifies the manufacturing processes while maintains their effectiveness at preventing crack formation.

Problems solved by technology

There were technical problem addressed earlier for us: how to create a type of concrete called fair-face concrete without requiring expensive finishing processes like mortar and grout, while still maintaining good appearance even at larger scales due to its unique design features.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

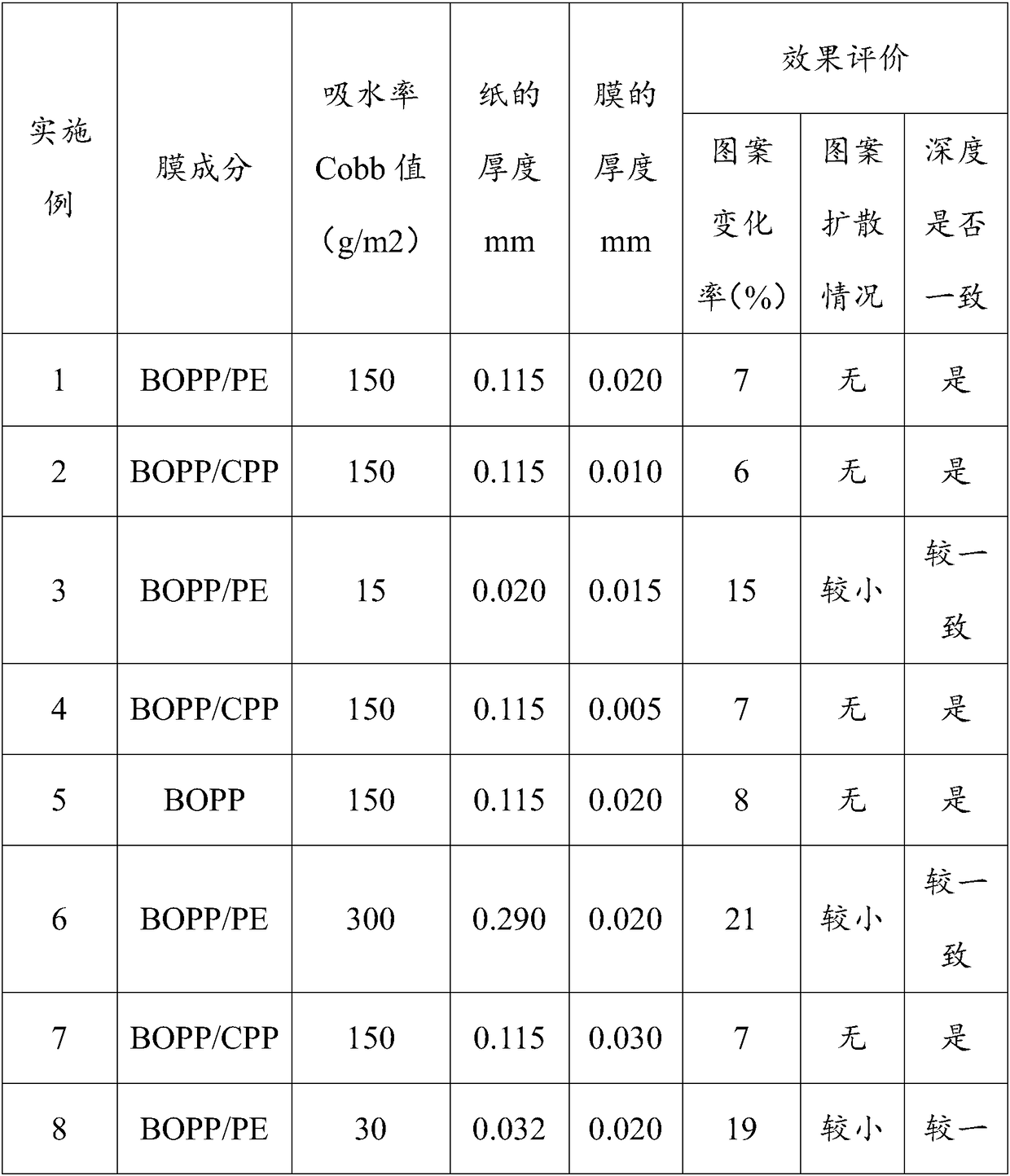

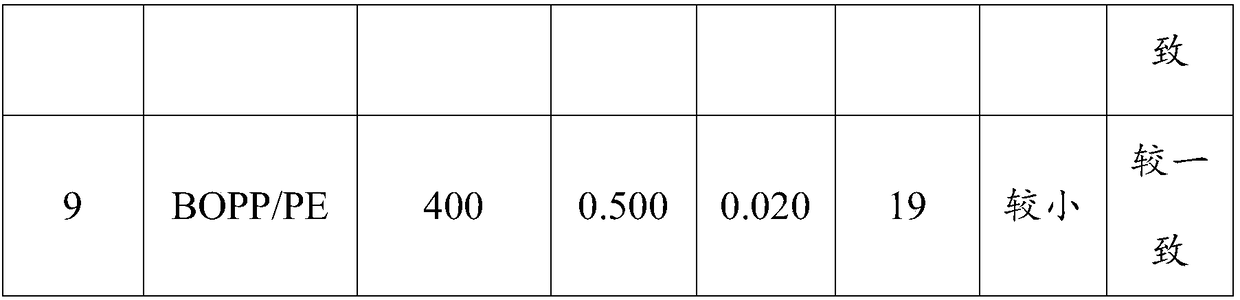

The invention discloses a method for manufacturing a decorative concrete product. The method solves the problems that an existing concrete surface pattern decoration method is complex in process and relatively poor in pattern forming fineness. According to the technical scheme, the method comprises the following steps that concrete decorative paper is prepared, wherein one surface of paper is fully coated with a film, the other surface of the paper is partially coated with the film according to a design pattern, then the concrete decorative paper is obtained, the paper is absorbent paper, andthe film is a hydrophobic film; the concrete decorative paper is flatly laid on the bottom of a mold, and the surface coated with the patterned film faces upwards; concrete is poured in the mold; curing and hardening are carried out, and then the mold is disassembled; finally, the concrete decorative paper is torn off; and the concrete product surface where the concrete decorative paper is torn off is washed with water, and a pattern is obtained on the concrete product surface. The method is simple in process, low in production cost, easy to operate and high in pattern forming precision.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Owner HUBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com