Decorative concrete floor structure and manufacturing method thereof

A production method and technology of concrete surface, which can be applied to coagulation pavement laid on site, climate change adaptation, roads and other directions, can solve problems such as large fluctuation of bearing strength deviation, fading of road surface, loss of function, etc., and achieve a simple and easy production method. The effect of the line, the structure is natural and beautiful, and the application range is wide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

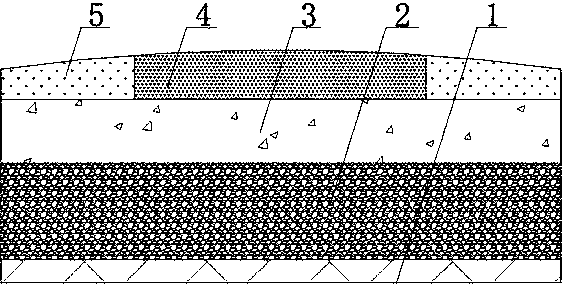

[0026] Such as figure 1 As shown, a decorative concrete ground structure, from bottom to top is: plain soil layer 1, graded crushed stone layer 2, sand-free macroporous permeable concrete layer 3 and decorative concrete surface layer; among them, the uppermost layer of decorative The permanent concrete surface layer is divided into three parts vertically along the surface of the sandless macroporous permeable concrete layer 3 laid thereon: the middle road surface and the side road surfaces on both sides; the center line of the middle road surface coincides with the center line of the road surface; The side roads on both sides extend from the side edges of the road to the middle road. The width of the side roads on both sides is the same, both are 300mm~500mm, and the rest is the middle road; There is a colored permeable concrete lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com