Spray-type ultrahigh-performance decorative concrete material and preparation method thereof

A decorative concrete, ultra-high-performance technology, applied in the field of building materials, can solve the problems of difficult to prepare complex multi-faceted and curved shape plates, unsatisfactory durability, easy deformation and cracking, etc., to achieve easy pumping and spraying, and bending strength. Low, good sag resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

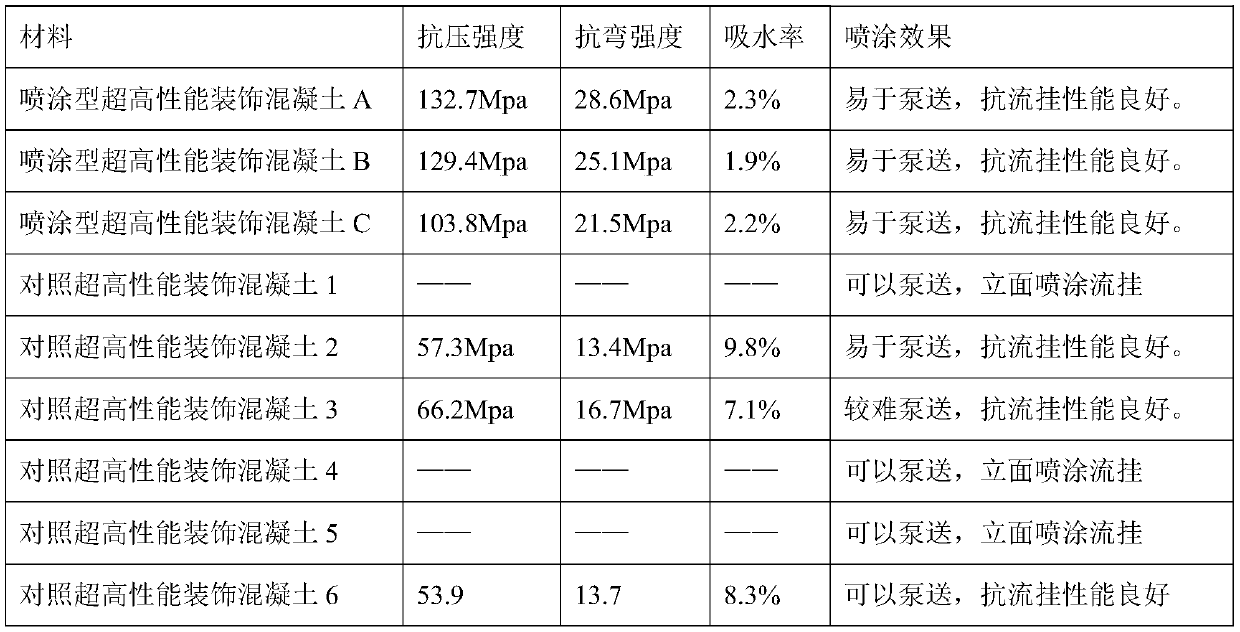

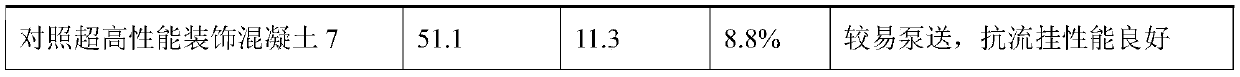

Examples

Embodiment 1

[0024] Spray-type ultra-high-performance decorative concrete A is prepared from the following raw materials in parts by weight: 1200 parts of cement, 180 parts of mineral admixture, 560 parts of 15-20 mesh quartz sand, 320 parts of 45-50 mesh quartz sand, 210 parts of 400-500 mesh quartz powder, 120 parts of expansion agent, 12 parts of water reducer, 16 parts of early strength agent, 1.2 parts of defoamer, 10 parts of polymer emulsion, 12 parts of bentonite, 0.3 parts of hydroxyethyl cellulose, 0.06 parts of starch ether, 80 parts of alkali-resistant glass fiber, 2 parts of pigment, and 120 parts of water.

[0025] The cement uses white Portland cement with a strength grade of 52.5.

[0026] The mineral admixture is a mixture of S95 grade granulated blast furnace slag powder and white silica fume in a weight ratio of 80:20. The silicon dioxide content of white silica fume is not less than 92%.

[0027] The expansion agent is the concrete expansion agent model HP-CSA produce...

Embodiment 2

[0061] Spray-type ultra-high-performance decorative concrete B is prepared from the following raw materials in parts by weight: 1100 parts of cement, 100 parts of mineral admixture, 400 parts of 15-20 mesh quartz sand, 400 parts of 45-50 mesh quartz sand, 200 parts of 400-500 mesh quartz powder, 75 parts of expansion agent, 7.5 parts of water reducer, 10 parts of early strength agent, 2 parts of defoamer, 16 parts of polymer emulsion, 15 parts of bentonite, 0.15 parts of hydroxyethyl cellulose, 0.03 parts of starch ether, 100 parts of alkali-resistant glass fiber, 0 parts of pigment, and 100 parts of water.

[0062] The source and composition of cement, mineral admixture, quartz sand, expansion agent, water reducer, early strength agent, defoamer, polymer emulsion, bentonite, hydroxyethyl cellulose, starch ether and alkali-resistant glass fiber are the same Example 1.

[0063] The specific preparation method of spray-on ultra-high performance decorative concrete B comprises t...

Embodiment 3

[0070] Spray-type ultra-high-performance decorative concrete C is prepared from the following raw materials in parts by weight: 800 parts of cement, 300 parts of mineral admixture, 450 parts of 15-20 mesh quartz sand, 300 parts of 45-50 mesh quartz sand, 400 parts of 400-500 mesh quartz powder, 50 parts of expansion agent, 10 parts of water reducer, 20 parts of early strength agent, 2 parts of defoamer, 20 parts of polymer emulsion, 10 parts of bentonite, 0.35 parts of hydroxyethyl cellulose, 0.07 parts of starch ether, 80 parts of alkali-resistant glass fiber, 3.5 parts of pigment, and 150 parts of water.

[0071] The source and composition of cement, mineral admixture, expansion agent, water reducer, early strength agent, defoamer, polymer emulsion, bentonite, hydroxyethyl cellulose and starch ether are the same as in Example 1.

[0072] The specific preparation method of spray-on ultra-high performance decorative concrete C comprises the following steps:

[0073] (1) Put t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com