Mold box and method of manufacturing a block

a manufacturing method and mold box technology, applied in the field of mold box and manufacturing method, can solve the problems of high overall production cost, block damage, and reduce the possibility of material hanging up in the mold box during removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

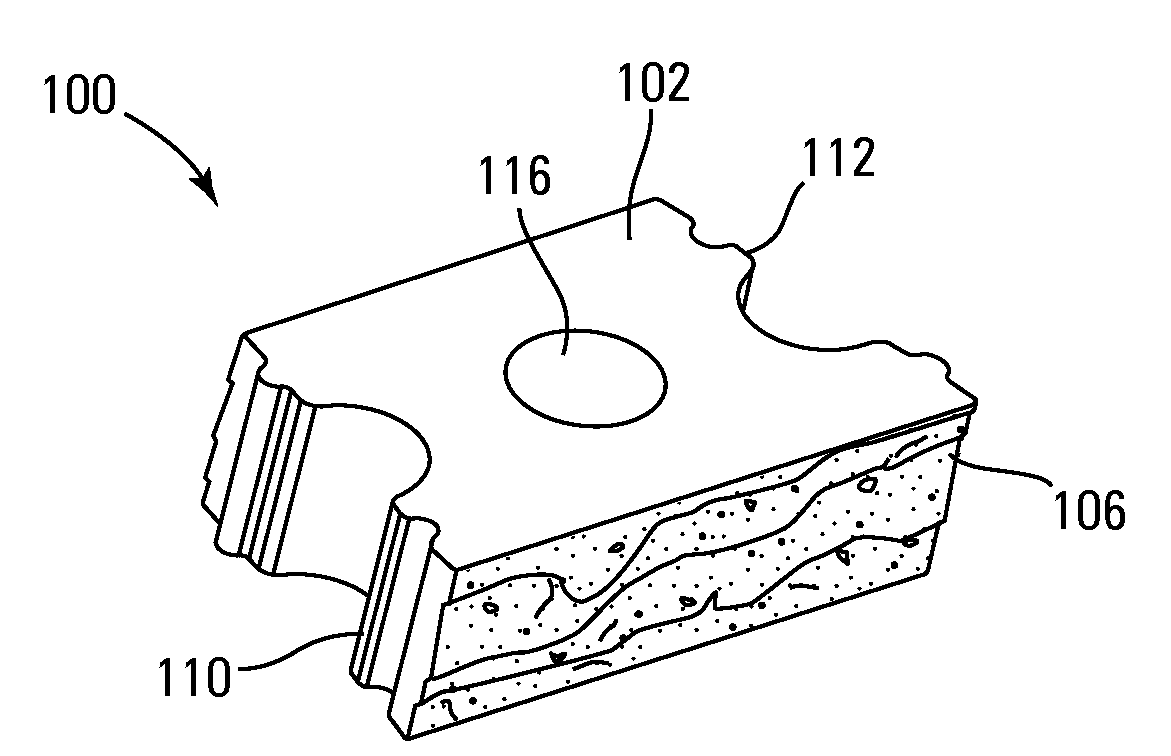

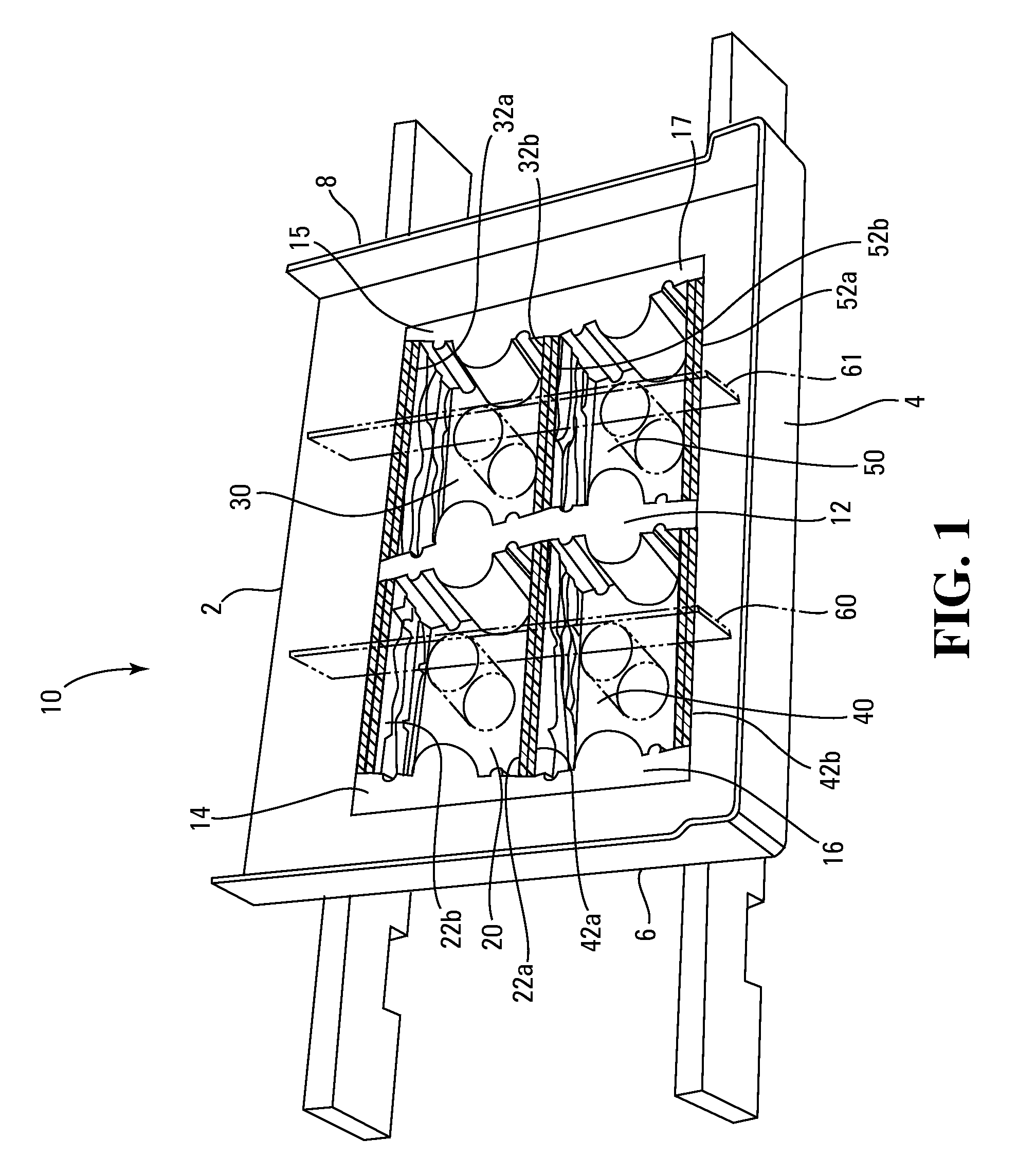

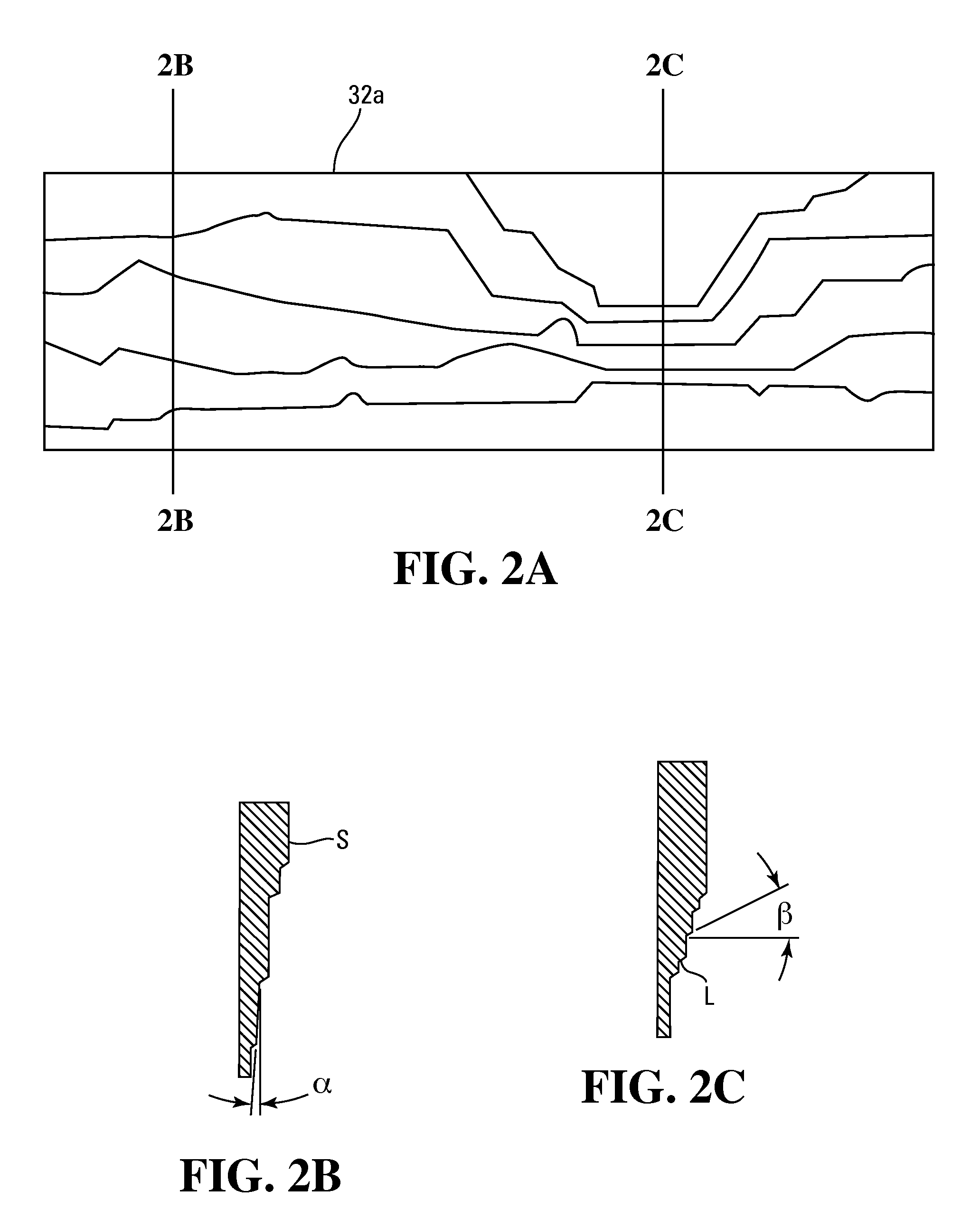

[0035]The present invention is a method of manufacturing a unique block face appearance using block face liners in a mold box. The block face liners in addition with other side liners and the mold box in which the liners are inserted are used to form multiple blocks at one time. The mold consisting of the mold box, the liners, and a lower plate (production pallet), forms cavities for the formation of blocks. Moldable material is placed into the mold and consolidated by vibration for a time sufficient to allow the material to retain the desired block shape when it is stripped or removed from the mold. In a manufacturing process, it is desirable to use one mold to form many blocks and for each block face to be unique and different from each other. The block face liner forms a block with a strata and / or ledge imprint resulting in the appearance of natural stone such as ledgestone or ashlar stone. The product (first set of blocks or slabs) is removed from the mold and moved to a curing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com