SOFC stack having a high temperature bonded ceramic interconnect and method for making same

a high-temperature bonding and interconnecting technology, which is applied in the direction of cell components, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of low cost of sofc systems, noise and vibration-free fuel cell technologies, etc., and achieve high-temperature bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

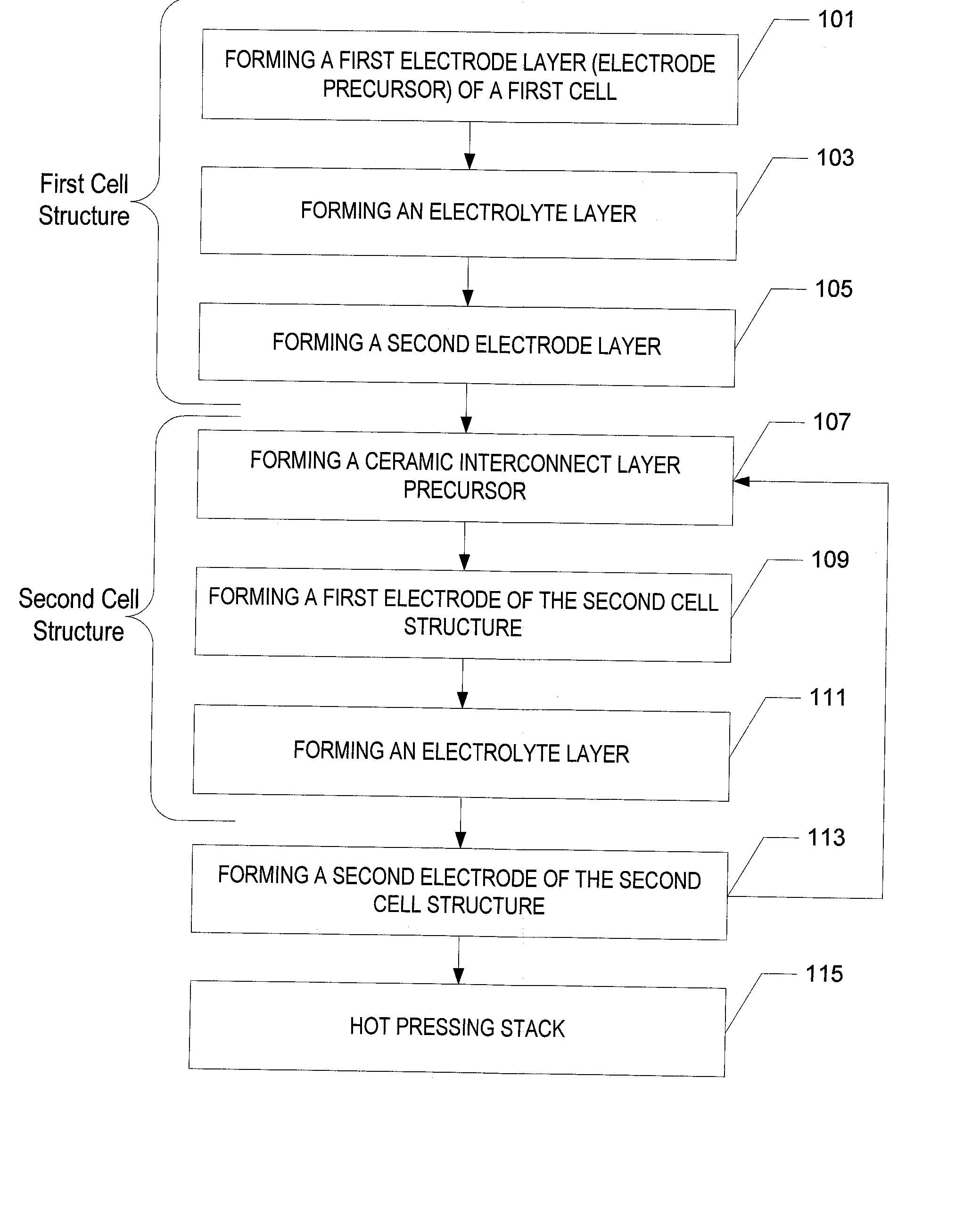

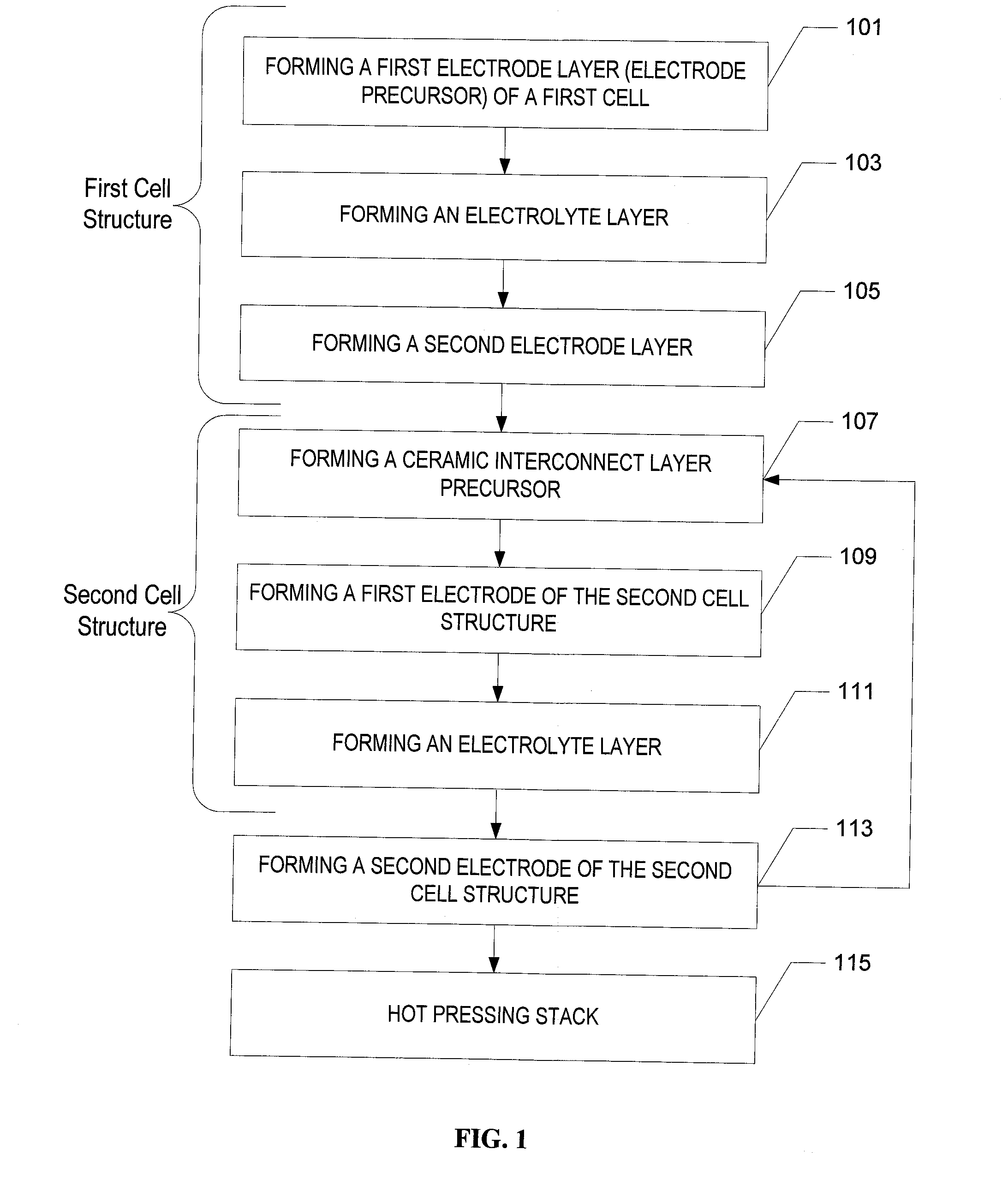

[0013] According to one embodiment, a method for making a SOFC stack is provided and may be produced according to a process flow illustrated in FIG. 1. An SOFC stack typically includes one or more SOFC cell structures, which generally include a cathode, anode, and interposed electrolyte. At step 101, a first electrode layer (electrode precursor) of a first cell is formed. The first electrode layer may include an anode or a cathode material. According to one embodiment, the first electrode is a cathode formed of a ceramic oxide material or precursor thereof. According to a particular embodiment, the cathode layer material includes lanthanum and manganese, and may further include strontium, forming a cathode commonly referred to as LSM (lanthanum strontium manganate). Alternatively, the first electrode layer may be an anode material, such as a cermet, that is a material having a ceramic phase and a metal phase, or a precursor thereof. The ceramic phase may include zirconia and the met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com