Preparation method of heat insulation tile blank capable of resisting high temperature of 2000 DEG C

A technology for thermal insulation tiles and green bodies, which is applied in the field of thermal protection material preparation, can solve the problems of low strength, poor oxidation resistance, complicated post-processing, etc., so as to improve the stability of ceramics, improve the sintering temperature, and ensure uniform preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

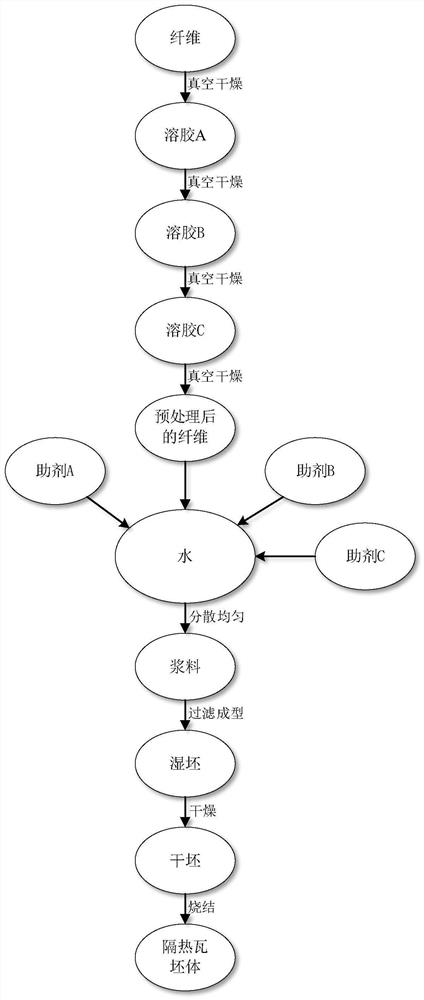

Image

Examples

Embodiment 1

[0037] A method for preparing a heat-insulating tile body that can withstand a high temperature of 2000°C, the specific steps are as follows:

[0038] Step 1. After impregnating the fiber in sol A, take it out and vacuum dry it (vacuum degree is 0.08MPa, drying temperature is 180°C), then transfer it to sol B, take it out after impregnating it and dry it in vacuum, and then transfer it to a hydrophobic tank for hydrophobic treatment, and then transferred to solution A for immersion, taken out and vacuum dried, then transferred to solution B for immersion, taken out and vacuum dried, then transferred to solution C for immersion, taken out and vacuum dried to obtain pretreated fibers;

[0039] The fibers are carbon fibers;

[0040] The sol A is an aluminum sol solution with a mass fraction of 15%;

[0041] The sol B is a zirconium sol solution with a mass fraction of 15%;

[0042] The solution A is a polyborazane solution; the solution B is a polycarbosilane solution; the solu...

Embodiment 2

[0057] A method for preparing a heat-insulating tile body that can withstand a high temperature of 2000°C, the specific steps are as follows:

[0058] Step 1. After impregnating the fiber in sol A, take it out and dry it in vacuum (vacuum degree is 0.09MPa, drying temperature is 120°C), then transfer it to sol B, take it out after impregnating it and dry it in vacuum, and then transfer it to the water-repellent tank for water-repellent treatment, and then transferred to solution A for immersion, taken out and vacuum dried, then transferred to solution B for immersion, taken out and vacuum dried, then transferred to solution C for immersion, taken out and vacuum dried to obtain pretreated fibers;

[0059] Described fiber is the composition of zirconia fiber, zirconium carbide fiber, silicon carbide fiber, boron nitride fiber, silicon nitride fiber, and its mass ratio is 6:1:1:1:1;

[0060] The sol A is an aluminum sol solution with a mass fraction of 5%;

[0061] The sol B is ...

Embodiment 3

[0076] A method for preparing a heat-insulating tile body that can withstand a high temperature of 2000°C, the specific steps are as follows:

[0077] Step 1. After impregnating the fiber in sol A, take it out and dry it in vacuum (vacuum degree is 0.10 MPa, drying temperature is 80°C), then transfer it to sol B, take it out after impregnating it and dry it in vacuum, and then transfer it to a hydrophobic tank for hydrophobic treatment, and then transferred to solution A for immersion, taken out and vacuum dried, then transferred to solution B for immersion, taken out and vacuum dried, then transferred to solution C for immersion, taken out and vacuum dried to obtain pretreated fibers;

[0078] Described fiber is the composition of carbon fiber, zirconium carbide fiber, silicon carbide fiber, boron nitride fiber, and its mass ratio is respectively 4:2:1:1;

[0079] The sol A is an aluminum sol solution with a mass fraction of 35%;

[0080] The sol B is a zirconium sol solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com