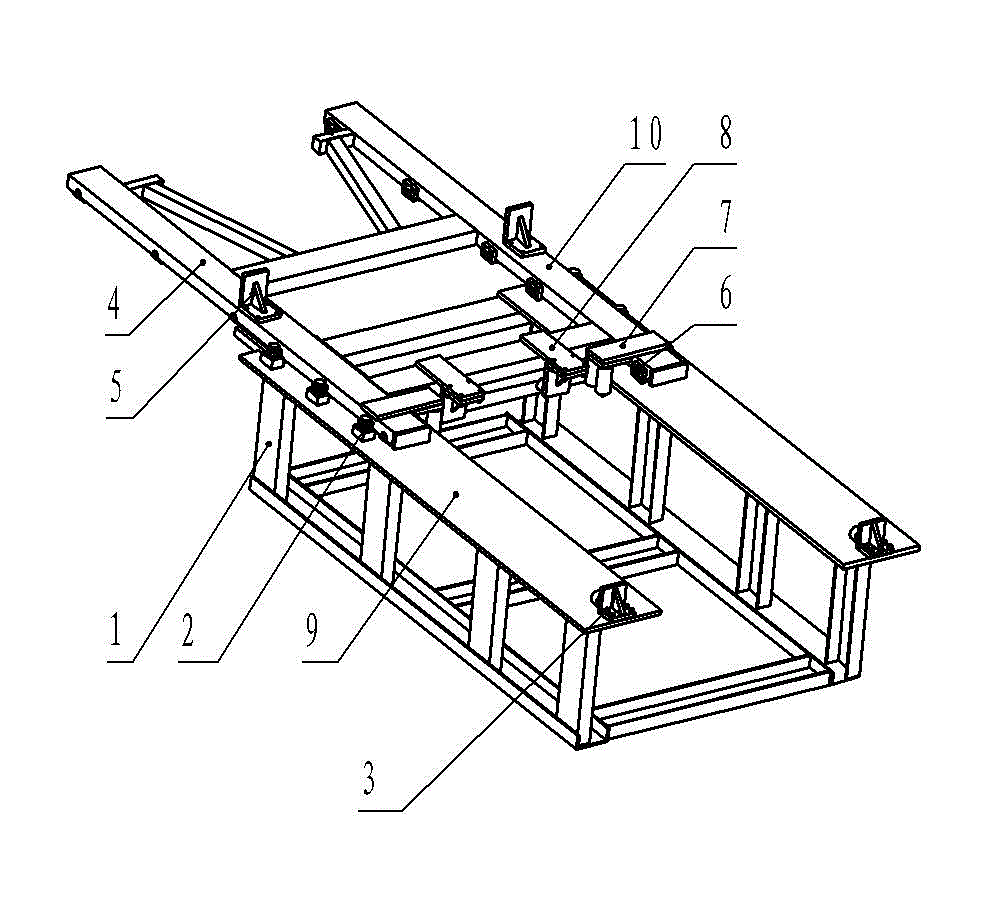

Quick mold change travelling table

A mobile worktable and fast technology, applied in the field of mechanical processing, can solve the problems of difficulty in changing large molds, time-consuming and laborious, affecting the service life of cranes, etc., and achieve the effect of reducing mold changing time, improving service life and reducing use time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing embodiment, the present invention is described in further detail:

[0013] A mobile workbench for rapid mold change, comprising a cuboid frame-type base 1, the base 1 is provided with two long slide plates 9 along the length direction, and the front ends of the long slide plates 9 are respectively provided with two limit blocks 3, and the ends of the limit blocks 3 The front end is provided with a polyurethane block, and the rear portion of each long slide 9 is respectively provided with three guide pulleys 2 along the length direction, and a rectangular sliding frame 4 is arranged on the top of the long sliding plate 9, and the sliding frame 4 has two longitudinal supports 10, each Five pulleys 6 are respectively arranged between the longitudinal support 10 and each long slide plate 9, and the pulleys 6 are installed on the lower plane of the longitudinal support 10, and a guide wheel 7 is respectively provided on the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com