Mouth-type mold capable of forming automobile sealing strip with two kinds of sections

A technology for automobile sealing strips and sections, applied in the field of die molds, can solve the problems of high cost, long debugging time, waste of manpower and material resources, etc., and achieve the effects of convenient operation, rapid mold change, and saving debugging cost and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

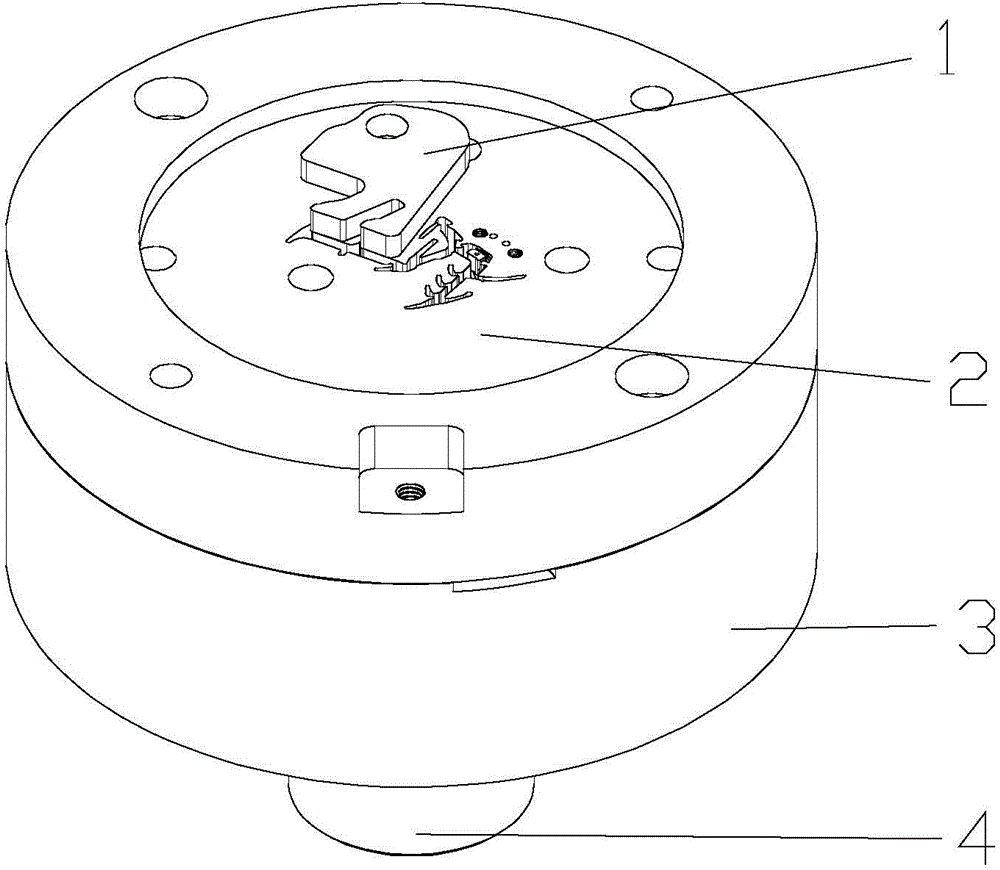

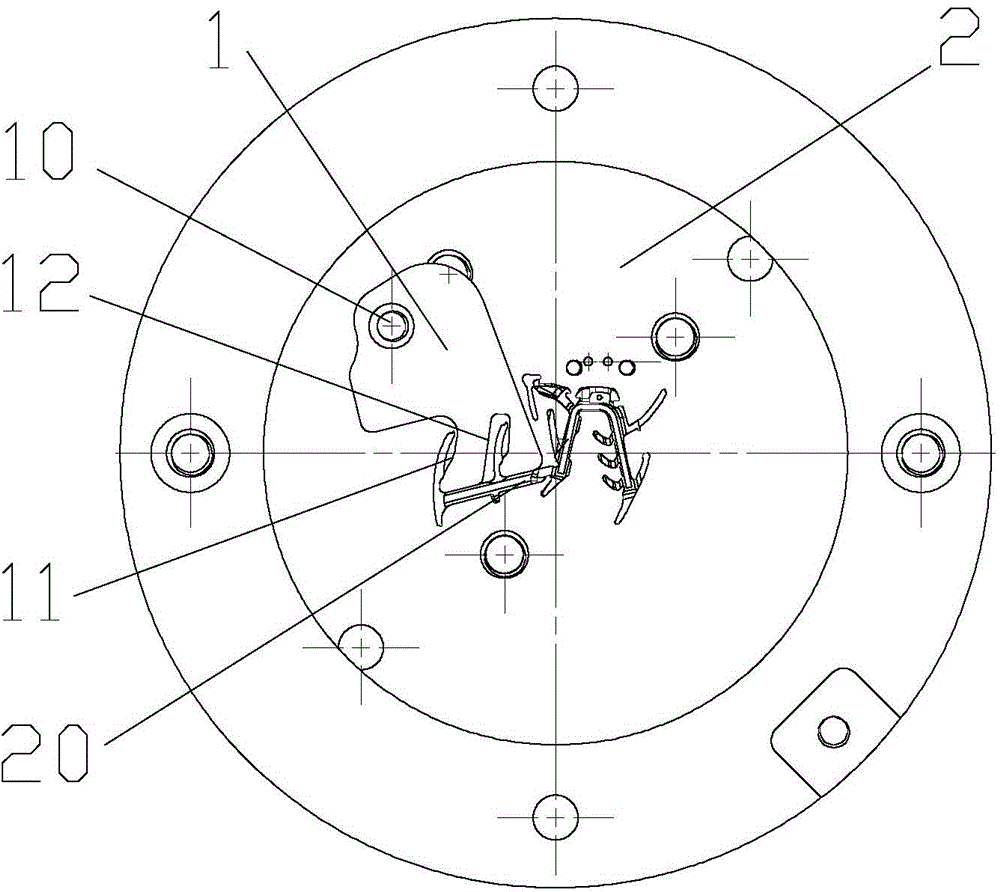

[0015] see Figure 1 to Figure 4 , a mouth mold capable of forming two kinds of cross-sections of the automobile weather strip of the present invention includes a base 3, a mouth panel 2 arranged on the base 3 and a sliding block 1 arranged on the mouth panel 2, wherein,

[0016] A first mold cavity opening 20 is provided in the center of the mouth-shaped panel 2, and the first mold cavity opening 20 forms an automobile weather strip of the first cross-section; the upper surface of the mouth-shaped panel 2 is provided with a rectangular positioning groove 21 and a screw thread Holes 22; a side wall surface of the positioning groove 21 closest to the first cavity mouth 20 is a slope 210;

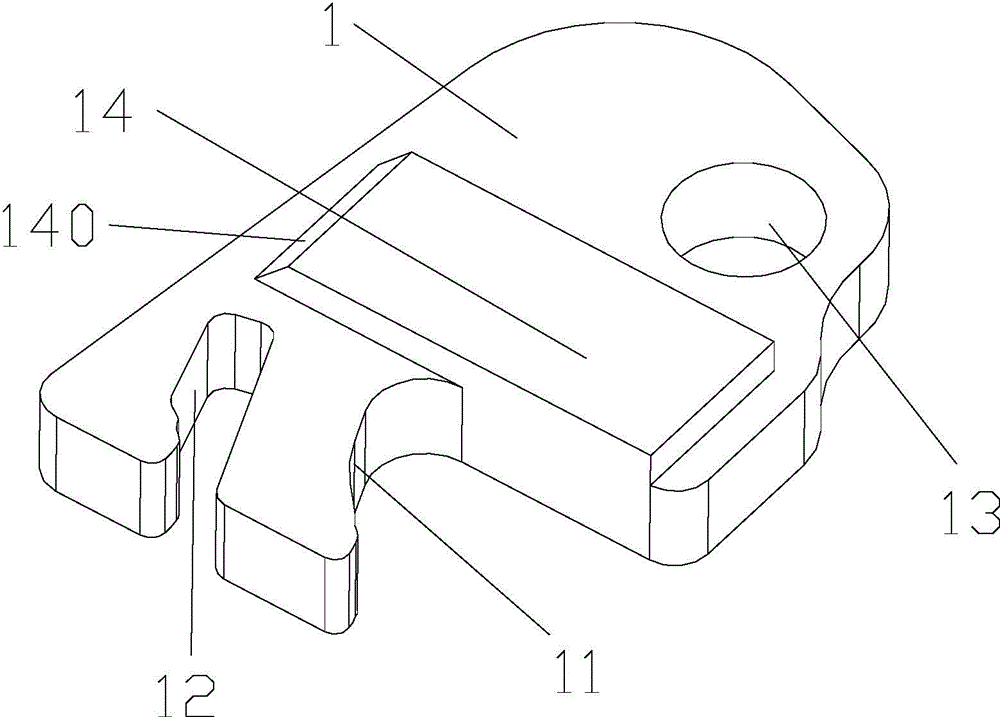

[0017] The sliding block 1 is provided with two forming notches 11, 12 and a mounting hole 13, and a positioning platform 14 protrudes from the lower surface of the sliding blocking bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com