Formula of binding layer slurry used for release film of synthetic leather and preparation method of the binding layer slurry

A bonding layer and release film technology, applied in coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of uneven coating surface and uneven coating, and achieve fast speed and good adhesion and flexibility, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

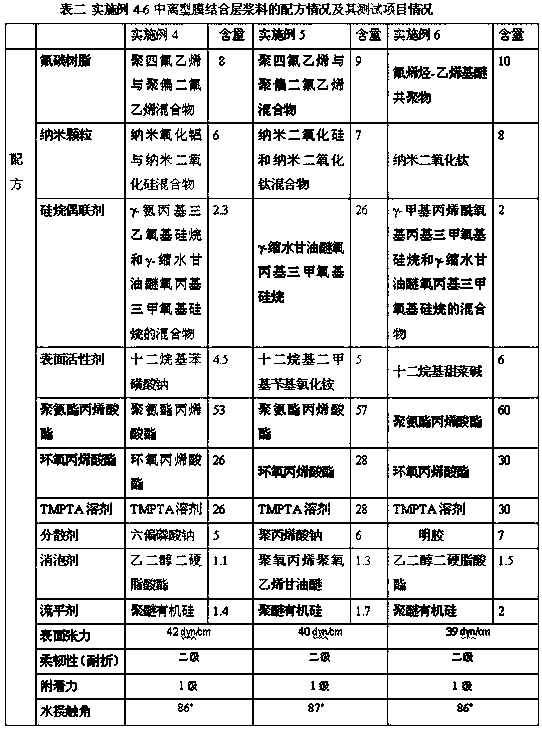

[0028] The preparation method of the slurry specially used for the production of the synthetic leather release film binding layer involved in this example: first weigh 5 parts of polytetrafluoroethylene, 2 parts of nano-alumina, and γ-aminopropyltriethoxysilane according to the formula quantity 0.5 parts, 3 parts of sodium dodecylbenzenesulfonate surfactant, 40 parts of polyurethane acrylate, 20 parts of epoxy acrylate and 20 parts of TMPTA solvent, 2 parts of dispersant sodium hexametaphosphate, defoamer ethylene glycol 0.5 part of distearate, 0.5 part of leveling agent polyether silicone.

[0029] Disperse the fluorocarbon resin, nanoparticles, and silane coupling agent in the TMPTA solvent with the assistance of the dispersant in the reaction kettle. After stirring evenly, continue stirring for 10 minutes at 40-50°C, and then add the surfactant, Polyurethane acrylate, epoxy acrylate, mix evenly, add defoamer to the obtained bonding layer slurry, let it stand for defoaming, ...

Embodiment 2

[0031] The preparation method of the slurry specially used for the production of synthetic leather release film binding layer involved in this example: first weigh 6 parts of polyvinylidene fluoride, 3 parts of nano-silicon dioxide, γ-glycidyl ether oxypropyl 1.8 parts of trimethoxysilane, 3.5 parts of surfactant dodecyl dimethyl benzyl ammonium chloride, 45 parts of polyurethane acrylate, 22 parts of epoxy acrylate and 22 parts of TMPTA solvent, 3 parts of dispersant sodium polyacrylate , defoaming agent polyoxypropylene polyoxyethylene glyceryl ether 0.7 parts, leveling agent polyether silicone 0.8 parts.

[0032]Disperse the fluorocarbon resin, nanoparticles, and silane coupling agent in the TMPTA solvent with the assistance of the dispersant in the reaction kettle. After stirring evenly, continue stirring at 50°C for 10 minutes, and then add the surfactant, polyurethane acrylic acid Ester, epoxy acrylate, mix evenly, add defoamer to the obtained bonding layer slurry, let i...

Embodiment 3

[0034] The preparation method of the slurry specially used for the production of synthetic leather release film bonding layer involved in this example: first weigh 7 parts of polyfluoroolefin-vinyl ether copolymer, 4 parts of nano-titanium dioxide, γ-methacryloyl 2.0 parts of oxypropyltrimethoxysilane, 4 parts of surfactant lauryl betaine, 50 parts of polyurethane acrylate, 24 parts of epoxy acrylate and 24 parts of TMPTA solvent, 4 parts of dispersant gelatin, defoamer 0.9 parts of ethylene glycol distearate, 1.1 parts of leveling agent polyether silicone.

[0035] Disperse the fluorocarbon resin, nanoparticles, and silane coupling agent in the TMPTA solvent with the assistance of a dispersant in the reaction kettle. After stirring evenly, continue stirring at 40°C for 10 minutes, and then add surfactant, polyurethane acrylic acid Ester, epoxy acrylate, mix evenly, add defoamer to the obtained bonding layer slurry, let it stand for defoaming, and finally add leveling agent to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com