Liner-provided cap and cap-provided threaded container

A liner and bottle cap technology, which is applied in the direction of bottle/container cap, container capping and capping, etc. It can solve problems such as insufficient lubricant function, large unsealing force, foreign matter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

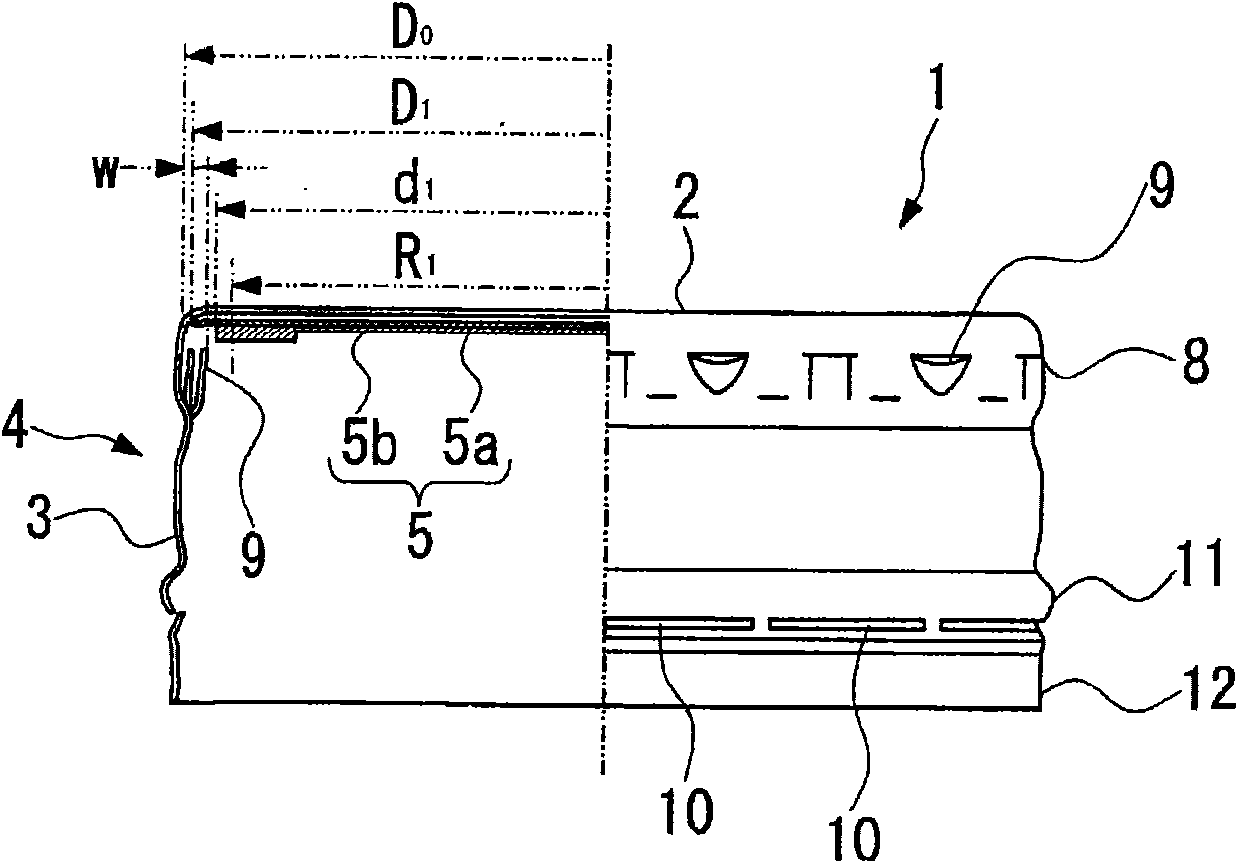

[0095] Below, for an embodiment of the bottle cap with liner of the present invention and the threaded container with bottle cap, refer to Figures 1 to 3 Be explained.

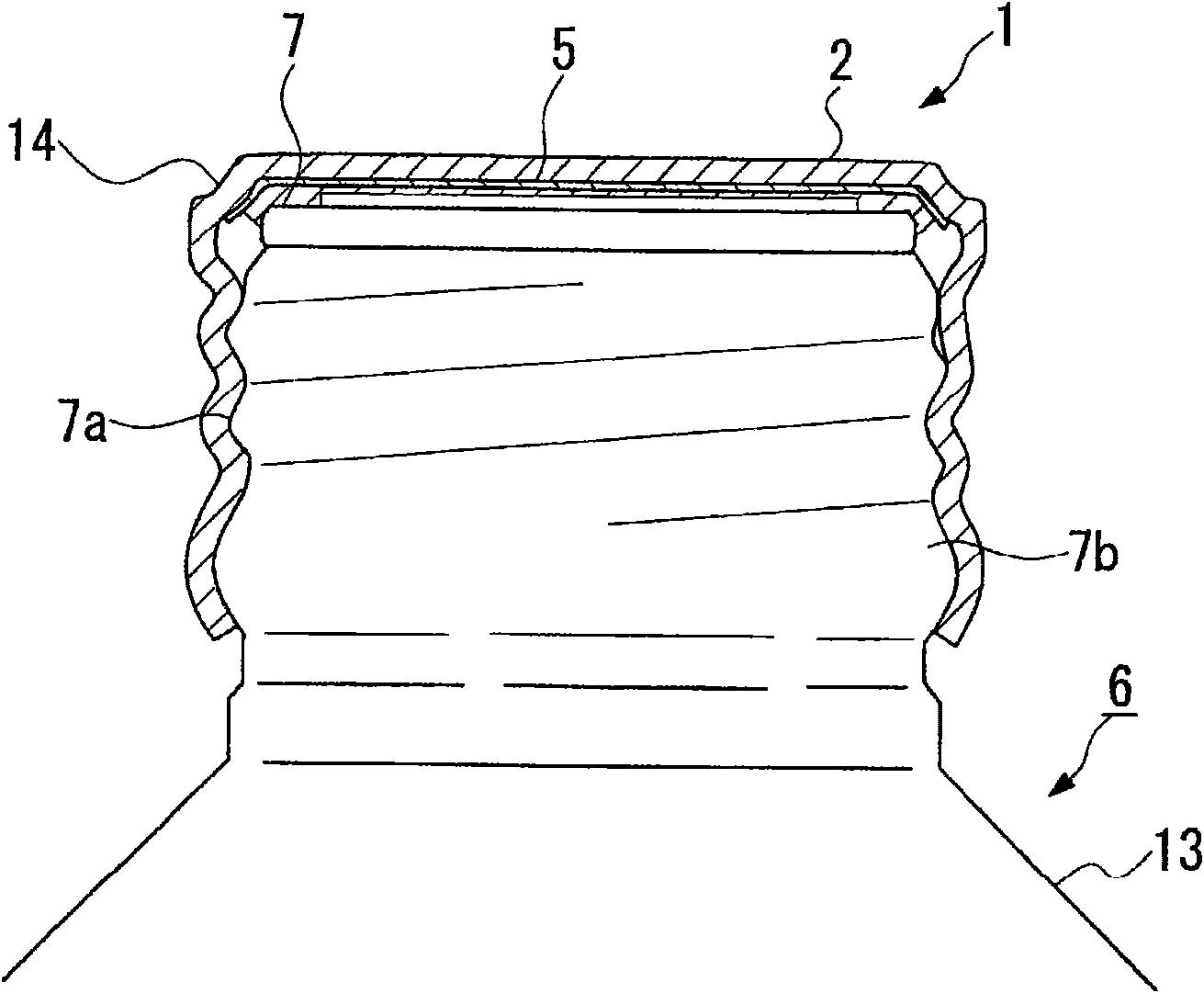

[0096] Such as figure 1 as well as figure 2 As shown, the bottle cap 1 of this embodiment is provided with: a bottomed cylindrical metal cap shell (bottle cap body) 4, composed of a top plate portion 2 and a cylindrical peripheral wall portion 3 suspended from the periphery of the top plate portion 2; The plate-shaped synthetic resin spacer 5 is provided on the inner surface of the top plate portion 2 in a state where it does not come off.

[0097] In addition, the threaded container with a cap of this embodiment, for example, the bottle (container) 6 has the cap 1 in a state where the cap 1 is fastened to the mouth portion (mouth portion) 7 . In addition, the threaded container of the present invention includes a bottle-shaped container, a PET bottle, a glass bottle, and the like.

[0098] The above-men...

Embodiment 1

[0169] Next, the results of comparative tests conducted to confirm the effects of the present invention will be described.

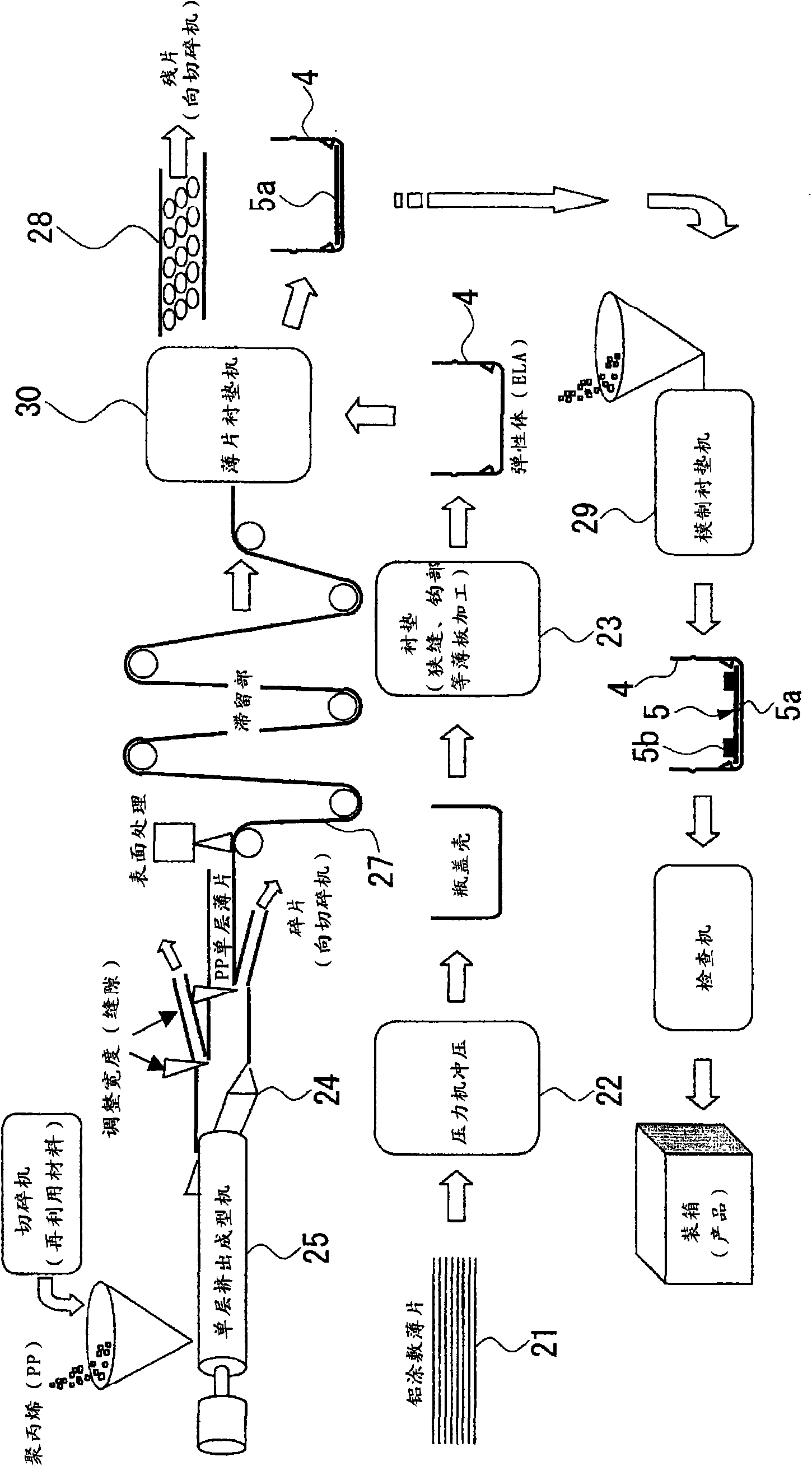

[0170] In this test, an aluminum alloy plate having a thickness of 0.25 mm coated on the inside and outside was molded into a cap shell 4 of a 38 mm PP cap (twist-off screw cap). This bottle cap shell 4 uses aluminum plate, and this aluminum plate uses the epoxy phenolic paint that has added polyolefin lubricant to 50mg / dm 2 Bake and coat. In addition, the polypropylene plate formed by the extruder 25 and the T-die 24 is punched into a hard sheet 5a of 37.8 mm, which is inserted into a bottle cap shell 4 with an inner diameter of φ38.05 mm. Twelve liner-locking hooks (liner-locking projections 9 ) protruding inward with a length of 1.0 mm are formed on the cap shell 4 substantially horizontally to the top surface. In addition, the position of the hook was set at a height of 1.5 mm from the top surface of the bottle cap. Also, the insertion is performe...

Embodiment 2

[0196] The gasket of the present invention was produced in the same manner as in Example 1, and compared with a conventional two-layer gasket material as a comparative example. In the present invention, the sliding layer changing the outer diameter of the sliding layer (hard thin sheet) is made, and after being inserted into the bottle cap shell, the sealing layer (soft layer) is molded by molding in the shell. In addition, the size of the sliding layer (hard sheet) was trial-manufactured by estimating the upper limit and lower limit of the present invention, and it was inserted into the bottle cap shell. About these, the same evaluation as Example 1 was performed. A conventional two-layer sheet was tested as a comparative example. In addition, for the sheet of Comparative Example, the same PP and styrene-based elastomer as in Example 1 were extruded and laminated from the double-layer extruder and T-die of the sheet forming machine, and the thickness was adjusted with coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com