Overlaying-ring ring shear apparatus as well as overlaying ring shear test

A ring shearing instrument and ring-type technology, applied in the field of geotechnical testing technology and deformation simulation, can solve the problems of strength parameter gap, influence of experimental results, influence of uneven material, etc. The effect of reducing running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

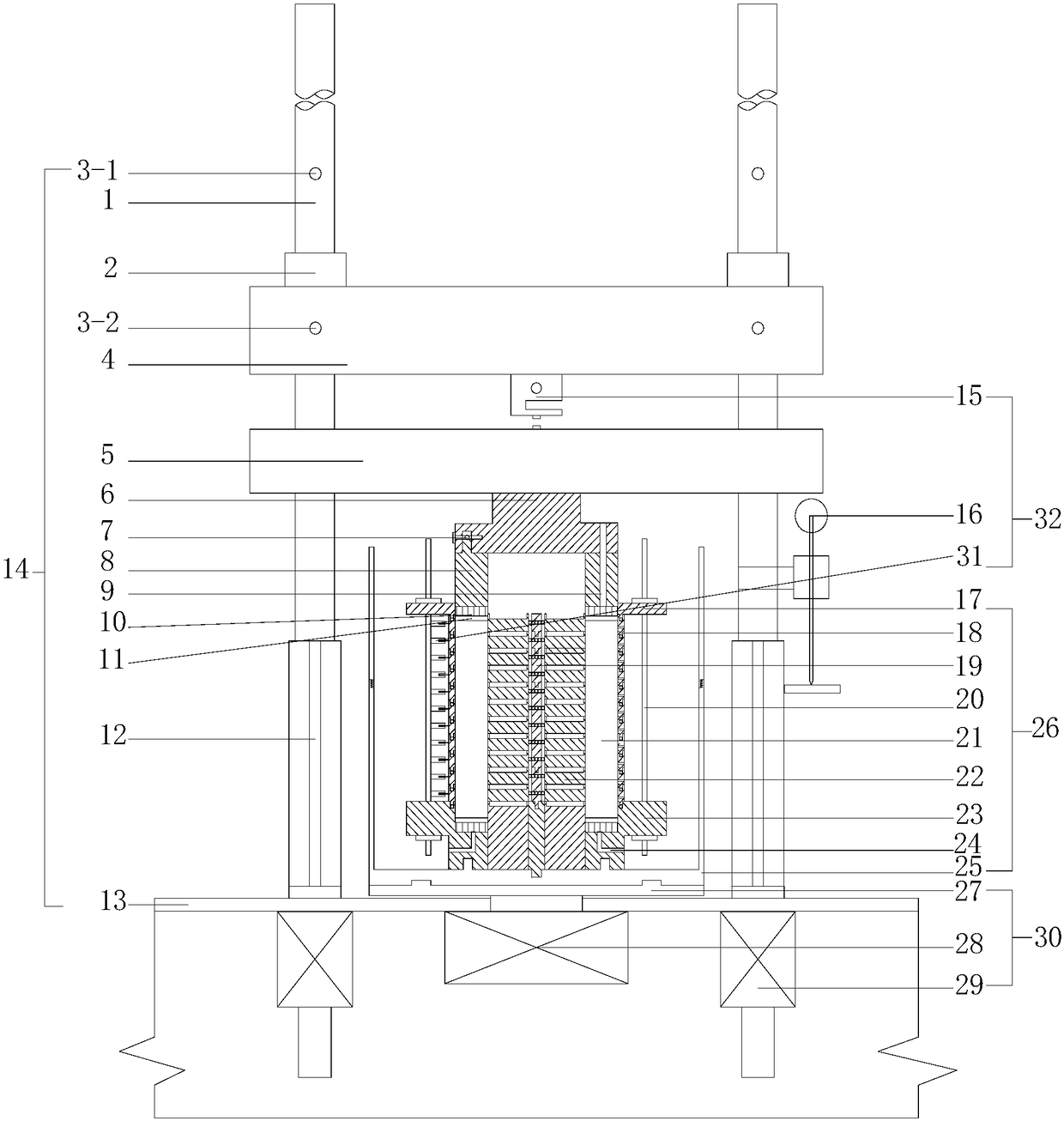

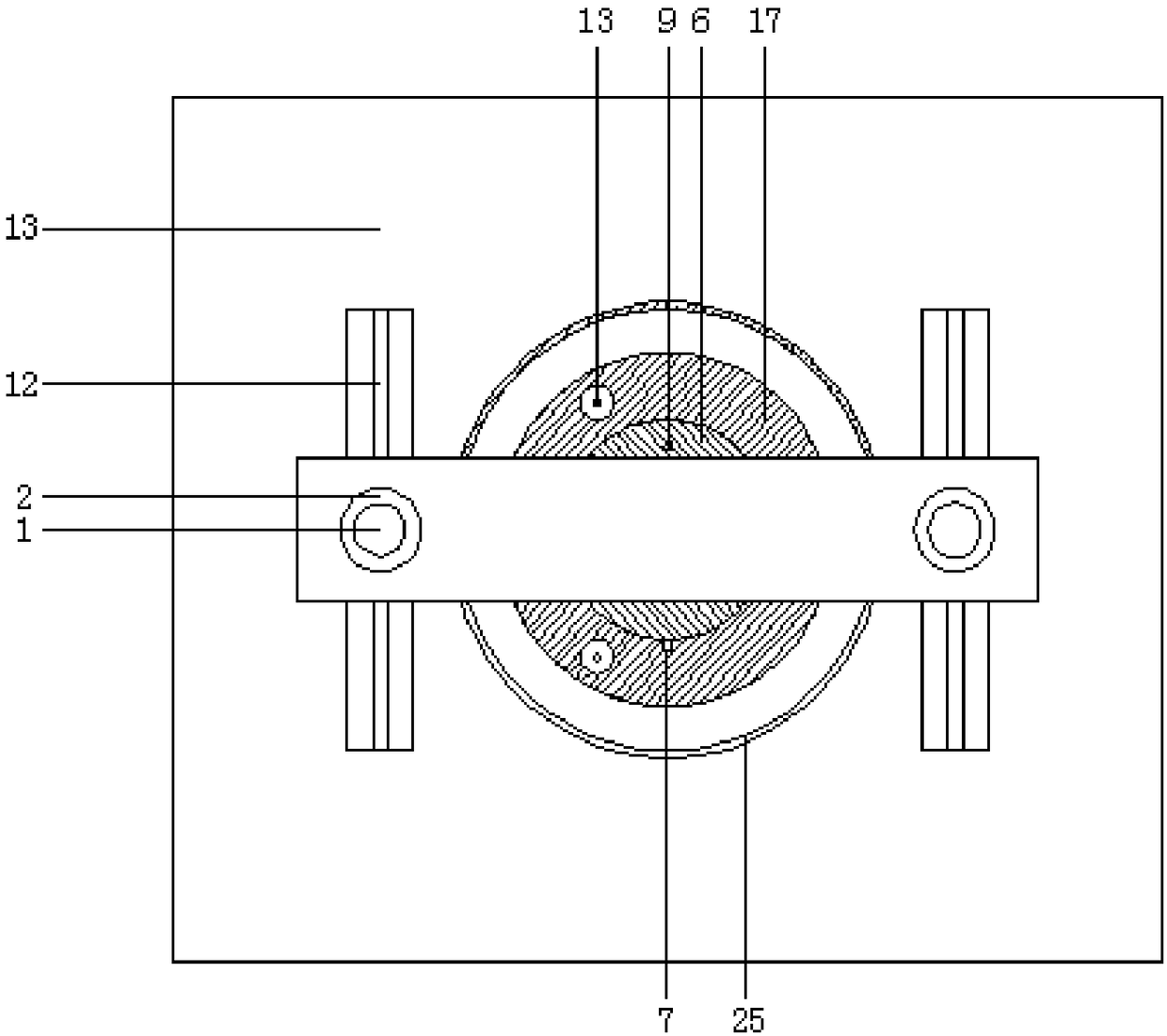

[0081] Example 1: Traditional Ring Shear Test

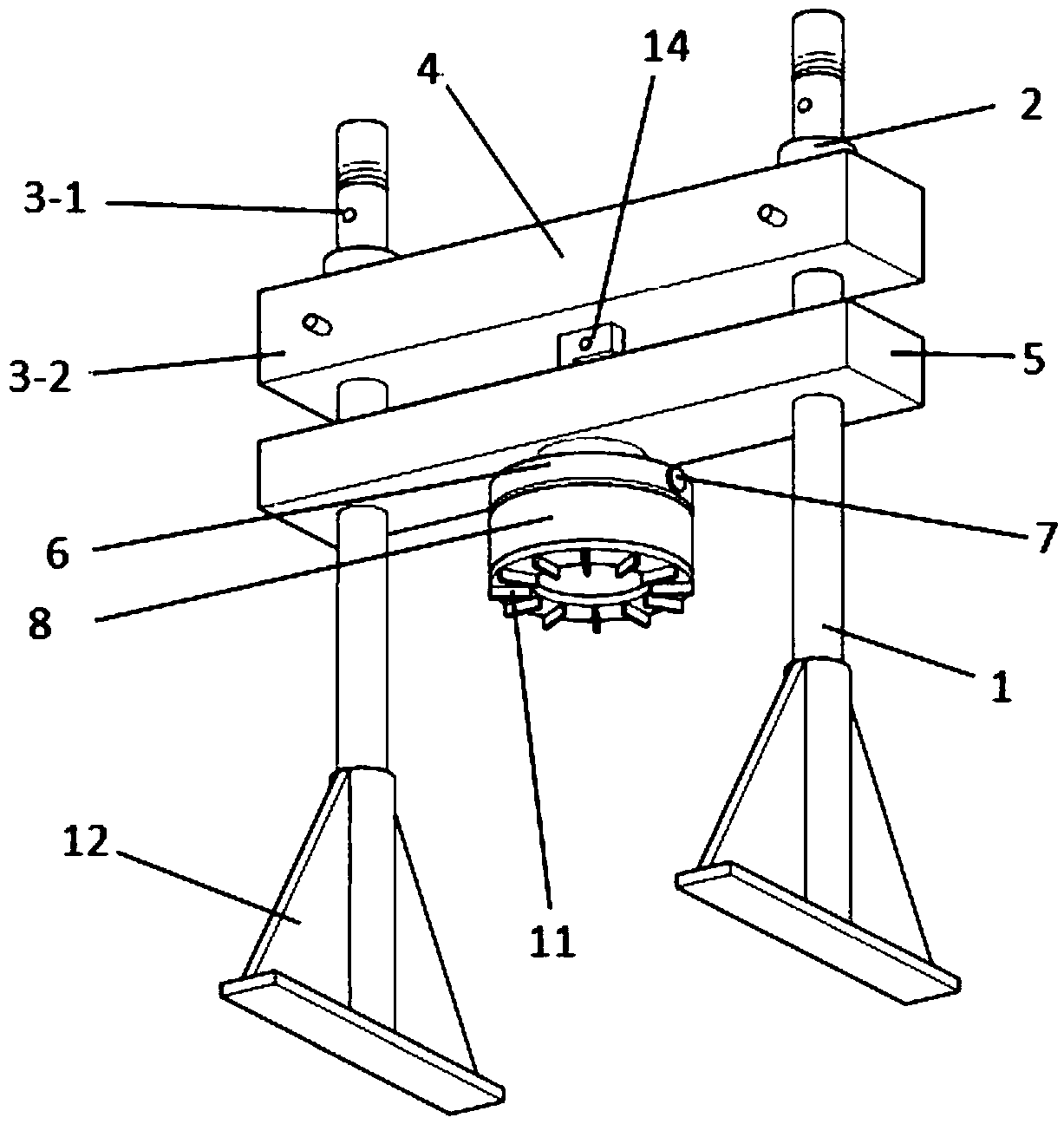

[0082] (1) Sample preparation: The annular soil sample (sample) is prepared by a traditional sample preparation device, and loaded into the lower shear box 23 . Keep a movable wall ring and a lamination, insert the central axis 19 of a lamination height into the bottom groove of the water bath box 25 and fix it, and put the collar 17 on it. A shorter shear box bracket 20 is selected for fixing, and the stacked ring shear box and the water bath box 25 are placed on the drive plate 27 to complete the sample preparation.

[0083] (2) Equipment debugging: Fix the fixed beam 4 to the position of the lowermost pin hole 3-1 on the column 1, and lock the locking nut. Push the movable beam 5 to the lower part until it contacts the upper surface of the sample.

[0084] (3) Consolidation: Start the vertical pressurization motor 29 to move the fixed beam 4 downward, make the stress gauge 15 contact the movable beam 5, and apply vertical pr...

example 2

[0086] Example 2: stacked ring shear test

[0087] (1) Sample preparation: For undisturbed soil samples, the method of filling layer by layer can be used for sample loading; for undisturbed soil samples, a special in-situ sampler can be used for soil sample collection and filling, and the final soil sample height should be less than the movable wall ring Group 18 and lamination group 22 are of the same height. After the soil sample is filled to the preset height, the upper collar 17 is covered and locked by the shear box bracket 20, and the stacked ring shear box and water bath box that have completed the sample loading are placed on the drive plate 27 and fixed, and the sample loading is completed ;

[0088] (2) Equipment debugging: Adjust the height of the fixed beam 4 and the water bath box 25 according to the height of the sample. Generally, the height of the fixed beam 4 and the height of the water bath box 25 are based on the fact that the movable beam 5 is not in cont...

example 3

[0091] Example 3: Simulation test of complex soil deformation

[0092] (1) Sample preparation: If the undisturbed soil sample is selected, a special in-situ sampler can be used to collect and fill the soil sample, or the model test soil sample can be stacked after scaled down according to the actual stratum conditions. After the soil sample is filled to the preset height, the upper collar 17 is covered and locked by the shear box bracket 20 to complete the sample loading;

[0093] (2) Equipment debugging and consolidation: The equipment adjustment and consolidation methods are the same as in Example 2.

[0094](3) Ring shear: After the consolidation is completed, install a displacement monitoring instrument to ensure that the instrument probes are in contact with the movable wall ring and the column support 12 respectively, insert steel nails into the through holes of the movable wall ring, and open it under the condition of maintaining vertical pressure Twist the motor 28 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com