Connection method for super-capacitor current collector and metal housing, and device therefor

A technology of supercapacitors and metal casings, which is applied in the manufacture of hybrid boxes/casings/packages and hybrid/electric double-layer capacitors. Low, low leakage rate, small welding deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

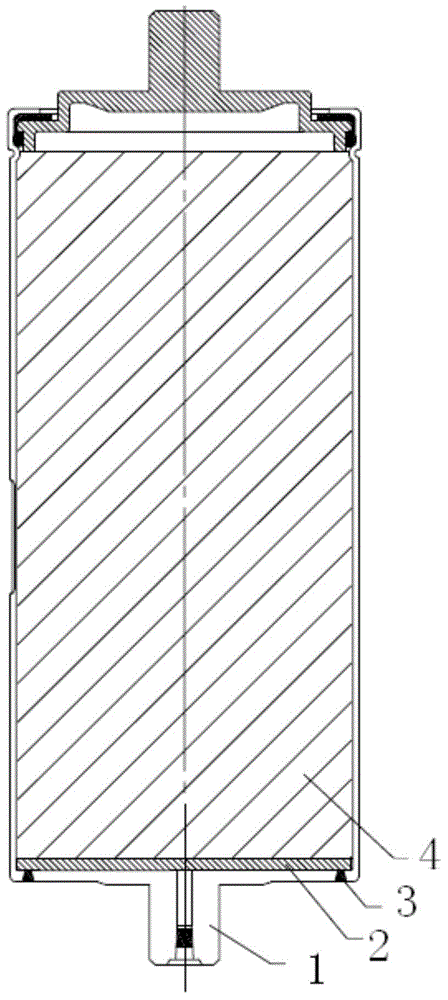

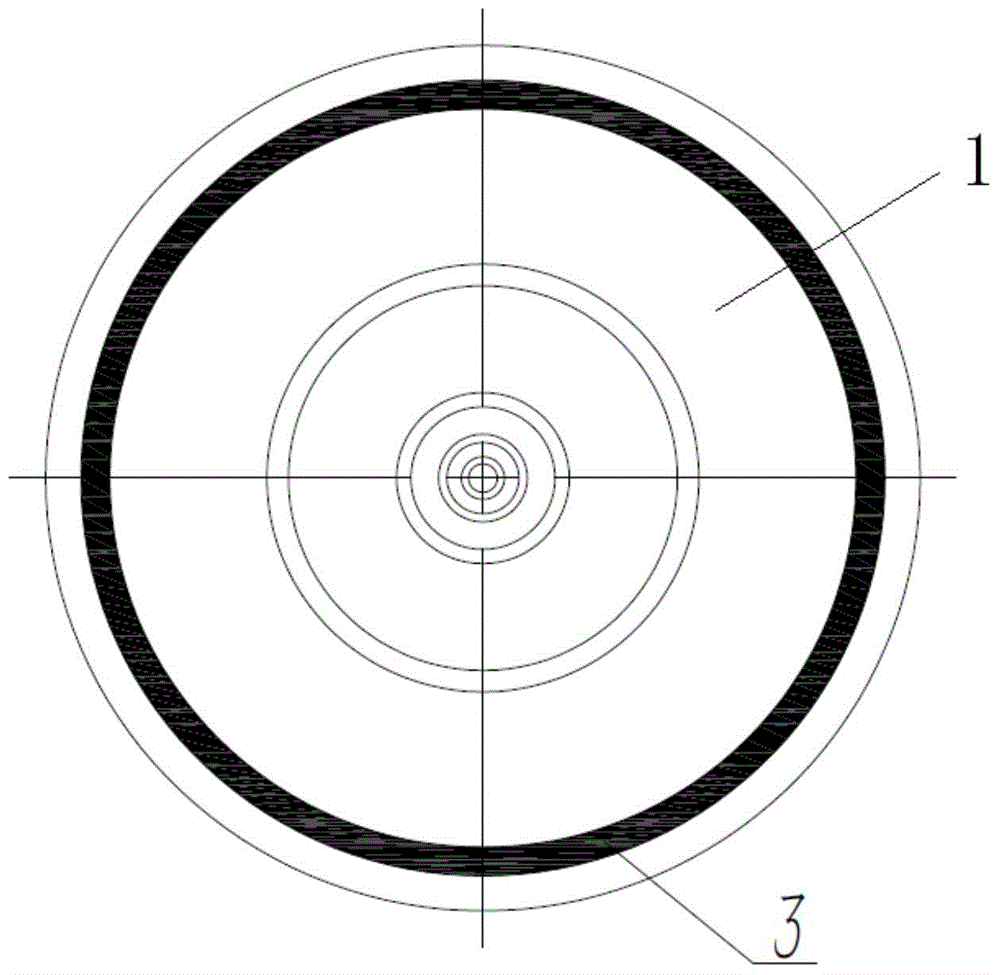

[0032] The patent of the present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

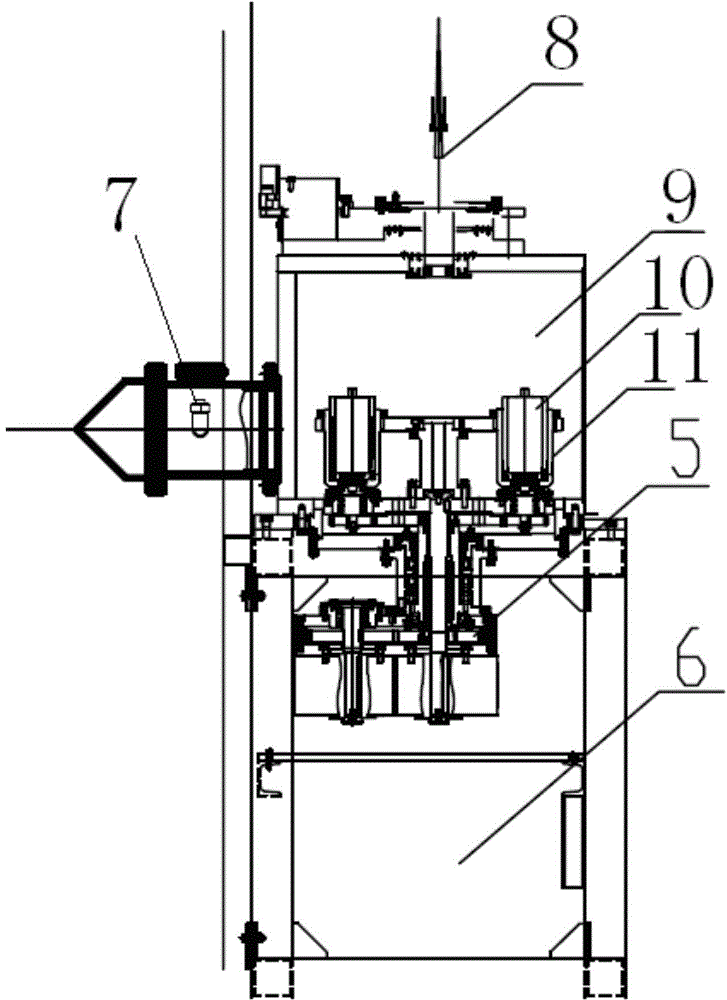

[0033] see image 3 and Figure 4 , the device provided by the present invention to realize the connection method of the supercapacitor current collector and the metal casing, the frame 6 is provided with an eight-station rotating mechanism 5 and a vacuum welding chamber 9, and the eight-station rotating mechanism 5 is provided with a supercapacitor fixing fixture 11 and the supercapacitor fixing fixture 11 is arranged in the vacuum welding chamber 9, the supercapacitor 10 is installed on the supercapacitor fixing fixture 11, the vacuum welding chamber 9 is connected with a vacuum exhaust hole 7, and also includes an electron beam welding torch 8 and an electron beam welding torch 8 It can extend into the vacuum welding chamber 9 and the electron beam torch 8 and the vacuum welding chamber 9 adopt a sealed structure.

[0034...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com