Mineral roasting reduction device and application method thereof

A mineral and roasting technology, applied in the field of mineral roasting and reduction devices, can solve problems such as neglect, and achieve the effect of preventing over-burning or under-burning, preventing secondary oxidation and reduction, and eliminating dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

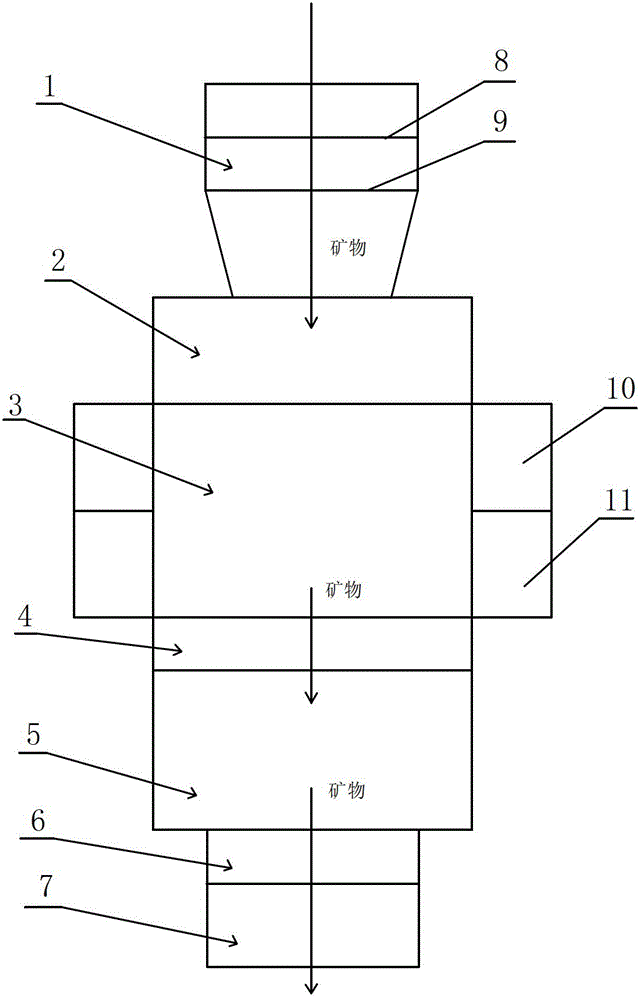

[0025] In conjunction with the accompanying drawings, a mineral roasting reduction device, which includes a feed area 1, a drying preheating area 2, a roasting oxidation reaction area 3, a pressure regulating area 4, a reduction reaction area 5, The discharge area 6 and the water-sealed cooling area 7. No. 1 automatic sealing device 8 and No. 2 automatic sealing device 9 are sequentially arranged above and below the feeding area 1 . A directional pressurization device is arranged on the upper part of the drying preheating zone 2, and the directional pressurization device is used for vacuuming. A layer of combustion agent addition device 10 and a second layer of combustion agent addition device 11 are sequentially arranged on the periphery of the roasting oxidation reaction zone 3 for supplying combustion agent. In the drying preheating zone 2, the roasting oxidation reaction zone 3 and the reduction reaction zone 5, a mineral turning device is arranged. A plurality of pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com