Self-heat dissipation type material tray for 3D printing

A 3D printing and self-heating technology, applied in the field of 3D printing, can solve the problems of energy consumption, large noise of cooling fan, impact, etc., and achieve the effects of accelerated efficiency, scientific electricity consumption, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

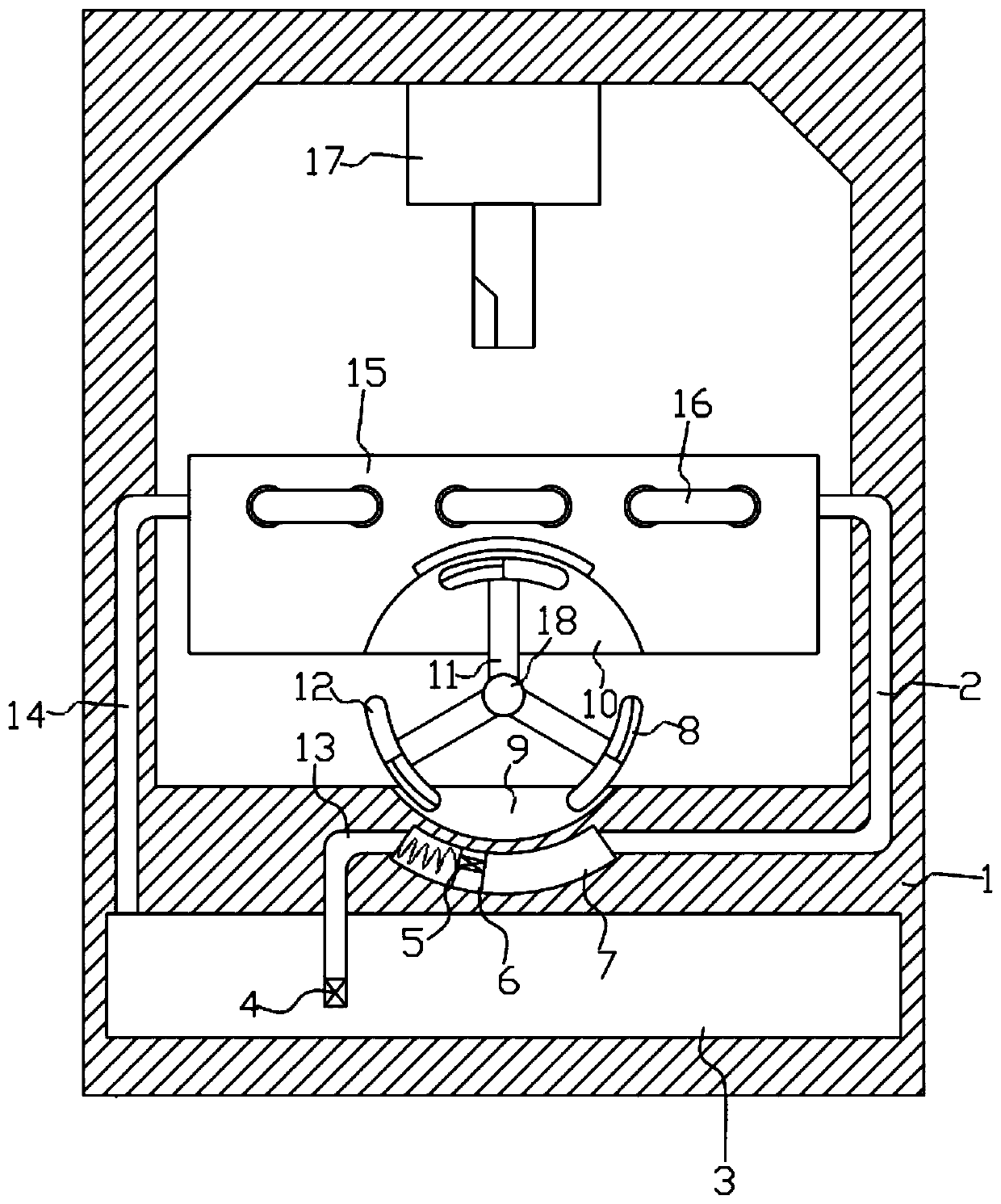

Examples

Embodiment 2

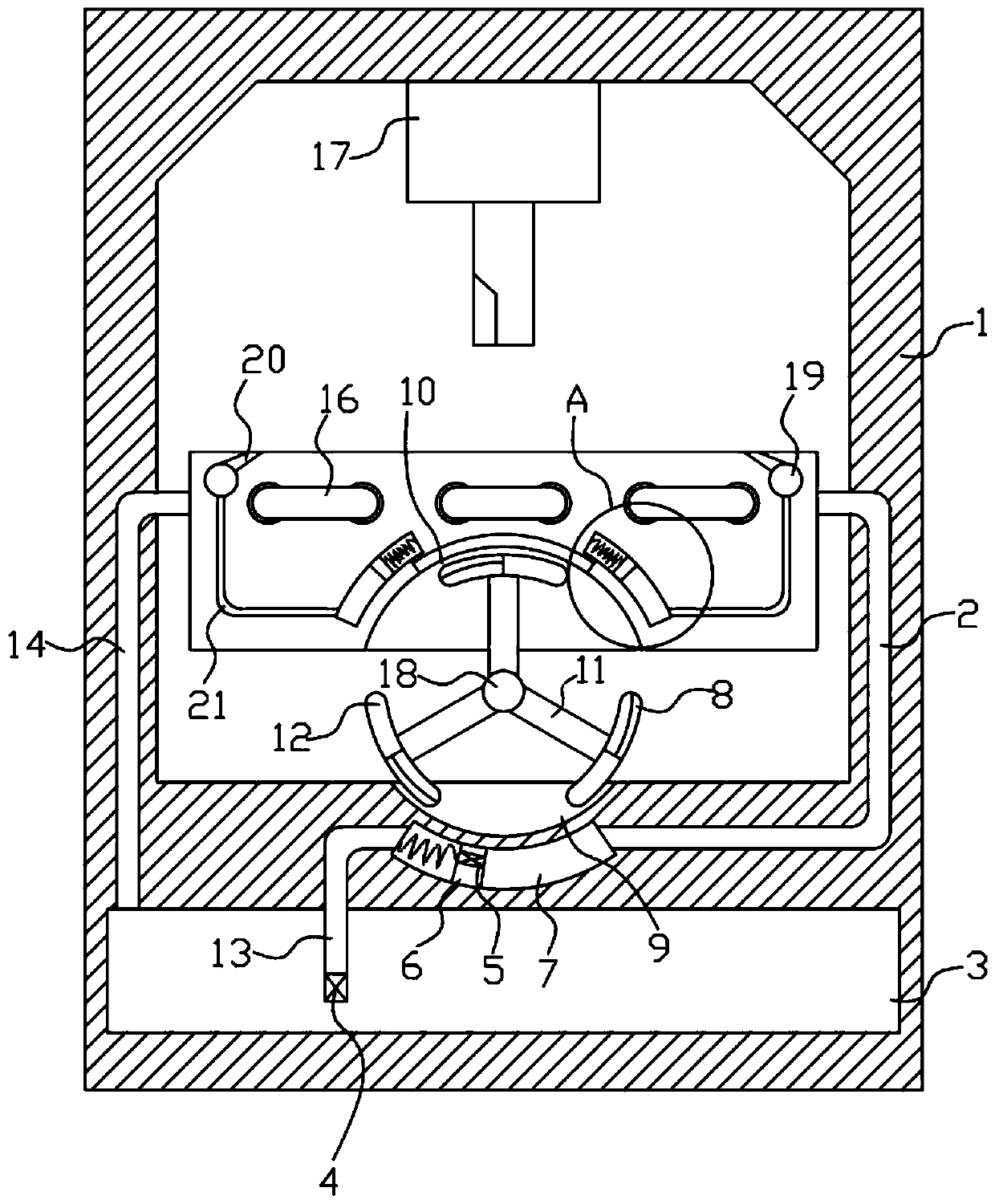

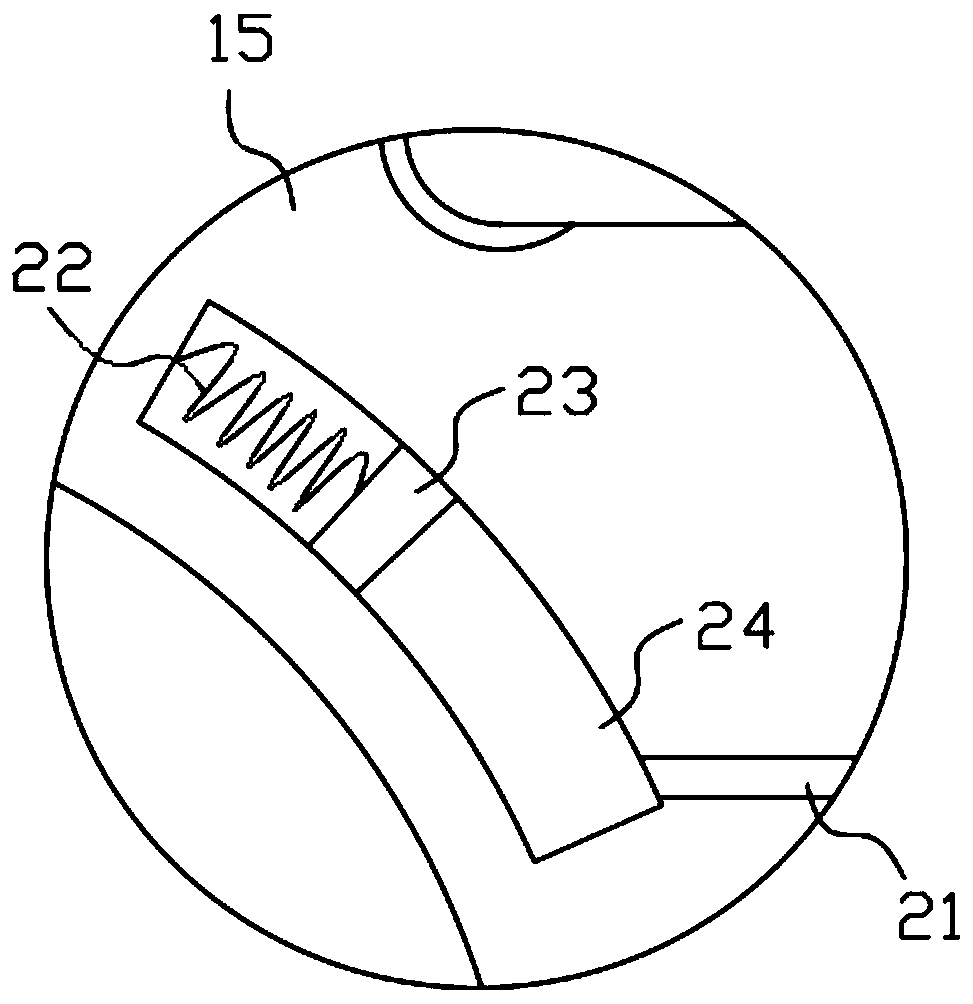

[0029] refer to Figure 2-3 , different from Embodiment 1, the supporting plate 15 is located above the first arcuate surface 10 and is symmetrically provided with two arc-shaped air chambers 24, and the arc-shaped air chamber 24 is sealed and slidably connected with a piston made of magnetic material 23. The upper end surface of the supporting plate 15 is provided with an annular cavity 19 along its circumference, and the upper end surface of the supporting plate 15 is evenly distributed with an inclination towards the middle of the supporting plate 15. An exhaust hole 20 is provided, and the exhaust hole 20 communicates with the annular cavity 19 , the piston 23 is elastically connected to the inner wall of the arc-shaped air chamber 24 through the second spring 22, and the end of the arc-shaped air chamber 24 near the second spring 22 is provided with a constant pressure hole communicating with the outside world, and the arc-shaped air chamber 24 is in communication with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com