Casting method for copper bush with high lead bronze content

A technology of bronze and copper sleeves, applied in casting molding equipment, casting molds, casting mold components, etc., can solve problems such as limited, and achieve the effects of reasonable casting process, good production efficiency, and high genuine product rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments, but is not limited thereto.

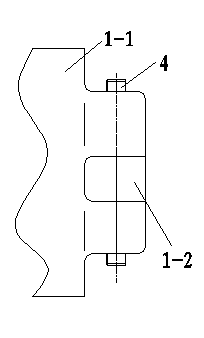

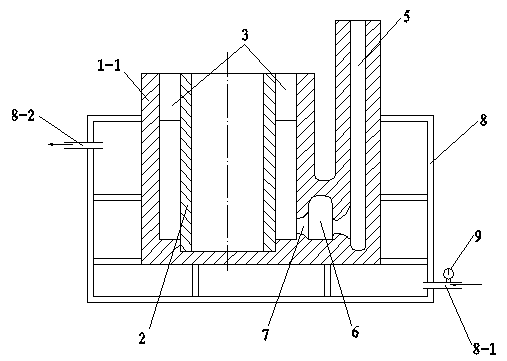

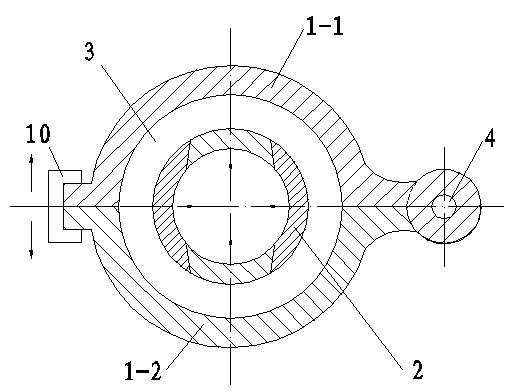

[0030] Such as figure 1 , 2 , 3, a method for casting a high-lead bronze sleeve with a relatively thick wall thickness and a relatively large shape, using a metal mold with a half-fit structure whose parting surface of the casting and its runner system is the casting outer mold , with the metal core of multi-parting structure as the casting inner mold, and the chemical components of the high-lead bronze copper sleeve and the weight percentages of each component thereof are Pb18~23%, Sn4~6%, Cu Surplus, and it: take the water cooling device that is located at the periphery of described casting mold as the cooling means of casting, and its specific steps include:

[0031] Step a, copper alloy smelting; the copper alloy smelting is to weigh copper, lead and tin according to the process ratio and put them into the furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com