Process for producing raw film for retardation film made of polypropylene resin

A technology of polypropylene-based resin and retardation film, which is applied in the field of coil film manufacturing for polypropylene-based resin retardation film, which can solve the problems of film transparency damage, etc., and achieve the effect of easy peeling and small retardation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

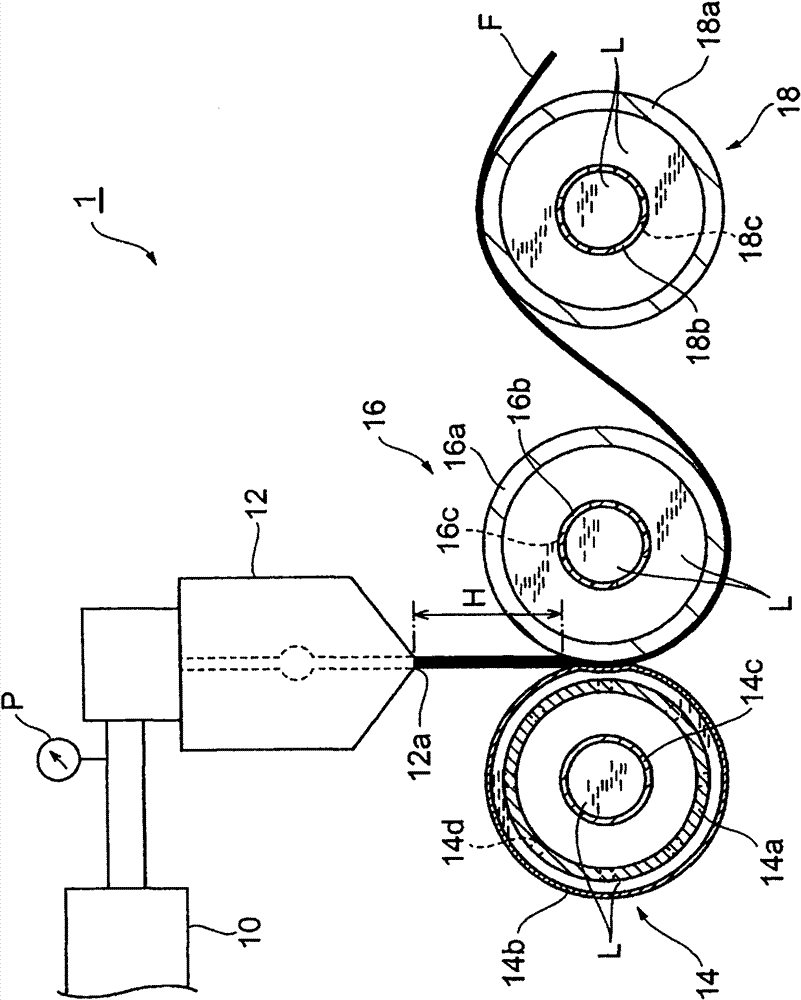

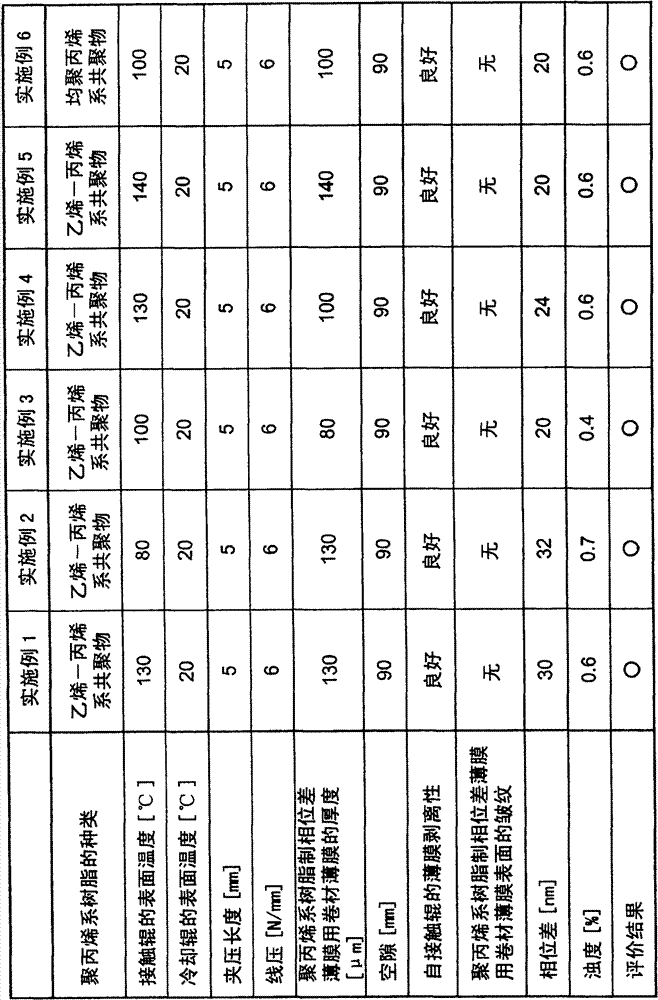

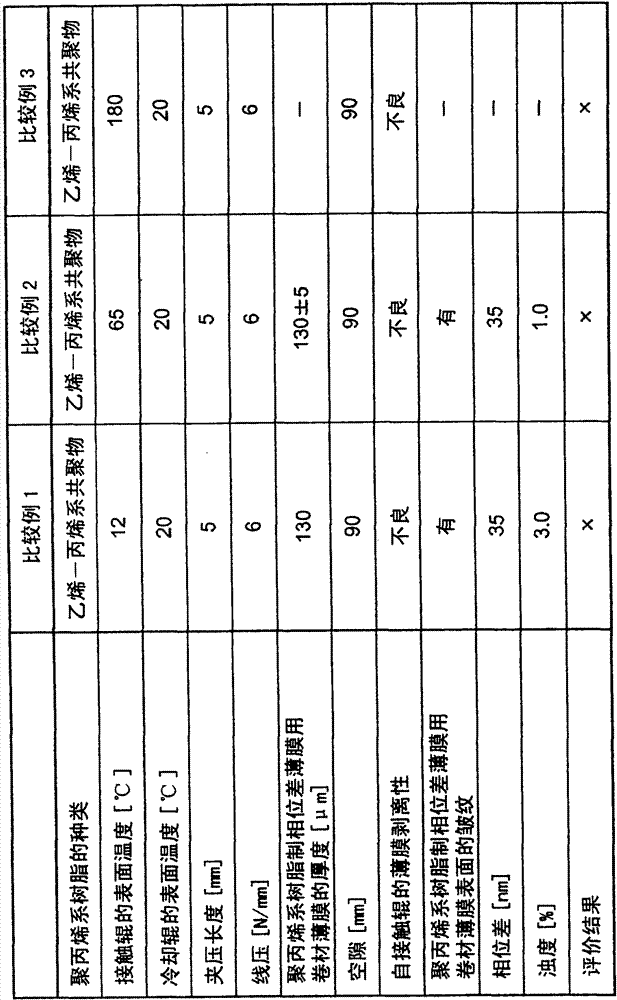

[0079] Below, based on Examples 1-6 and Comparative Examples 1-3 and Figure 1 ~ Figure 3 , the present invention will be described more specifically, but the present invention is not limited to the following examples.

[0080] (Example 1)

[0081] Using a 90mm¢extruder 10 (screw: L / D=32) heated at 250°C, an ethylene-propylene copolymer (ethylene content=5% by weight), Tm (melting point)=134°C, MFR (melt flow rate) = 8g / 10 minutes) melt kneading, and feed from the extruder 10 to the adapter (adater) and T-die 12 (both set to 250°C) that are installed next to the extruder 10, A resin film (molten resin) of an ethylene-propylene copolymer in a molten state is ejected from an ejection port (die lip) 12a of the die 12 . The temperature of the molten resin in the discharge port 12a portion of the T-die 12 was 250°C. Also, use figure 1 The touch roll 14 and the cooling roll 16 shown pinch the molten resin with a nip length of 5 mm and a linear pressure of 6 N / mm, and cool and so...

Embodiment 2

[0084] Except having set the surface temperature T2 of the thin metal outer cylinder 14b of the touch roll 14 to 80 degreeC, it carried out similarly to Example 1, and obtained the roll film F for polypropylene resin retardation films of Example 2.

Embodiment 3

[0086] In addition to setting the surface temperature T2 of the thin-walled metal outer cylinder 14b of the touch roll 14 to 100°C, the speed of the touch roll 14 was set to 15.9m / min, and the speed of the cooling rolls 16 and 18 were both set to 17.4m Except for / min, it carried out similarly to Example 1, and obtained the roll film F (thickness: 80 micrometers) for polypropylene-type resin retardation films of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com