Casting method for high-lead bronze

A bronze and high-lead technology, applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve limited and other problems, and achieve the effect of reasonable casting process, low production cost and high authenticity rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments, but is not limited thereto.

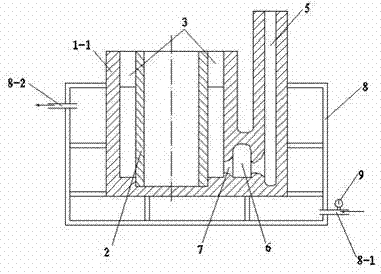

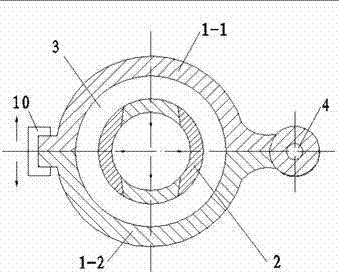

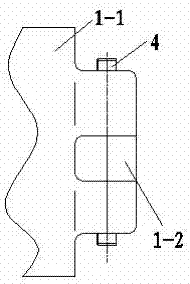

[0030] As shown in Figures 1, 2, and 3, a casting method for a high-lead bronze sleeve with a relatively thick wall thickness and a relatively large shape. The parting surface of the casting and its runner system is a metal with a Huff joint structure. The mold is a casting outer mold, and a metal core with a multi-part type structure is a casting inner mold, and the chemical composition of the high-lead bronze copper sleeve and the weight percentages of each component are Pb18~23%, Sn4 ~6%, the remaining amount of Cu, and it: the water cooling device arranged on the periphery of the casting mold is used as the cooling method of the casting, and the specific steps include:

[0031] Step a, copper alloy smelting; the copper alloy smelting is to weigh copper, lead and tin according to the process ratio and put them into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com