Laser synthesis method for barium dititanate ferroelectric ceramics

A technology of ferroelectric ceramics and barium titanate, which is applied in the field of preparation of ferroelectric ceramic materials, can solve problems such as limited applications, and achieve the effects of short time consumption, low energy consumption, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] BaCO 3 and TiO 2 The powders were mixed in a molar ratio of 1:2, ground in an agate mortar for 1 h, dried at 150°C for 2 h, then ground for 2 h in an agate mortar, and then pre-fired: starting from room temperature, heating at a rate of 3°C / min The temperature was raised to 900 °C and kept for 12 h in an air atmosphere, and then cooled with the furnace. The pre-fired powder was compacted under a pressure of 20 MPa and held for 60 s. The green body has a diameter of 13 mm and a thickness of 8 mm.

[0030] Place the green body on a horizontal sample stage, and use CO 2 The laser beam irradiates the front side of the sample vertically for 60s, then turn off the laser, turn the sample over, repeat the above steps, and irradiate the back side of the sample for 120s. During this process, the laser power was 800 W, and the defocus distance was 120 mm. Turn off the laser and let the sample cool down naturally. The prepared samples were annealed to obtain barium dititanate...

Embodiment 2

[0033]BaCO 3 and TiO 2 The powders were mixed at a molar ratio of 1:2, ground in an agate mortar for 1 h, dried at 150 °C for 2 h, and then ground in an agate mortar for 2 h. The fully mixed powder was compacted under a pressure of 20 MPa and held for 60 seconds. The green body has a diameter of 13 mm and a thickness of 8 mm.

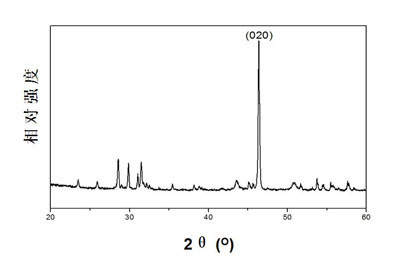

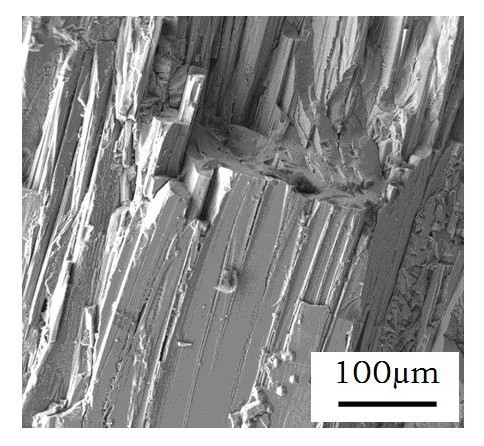

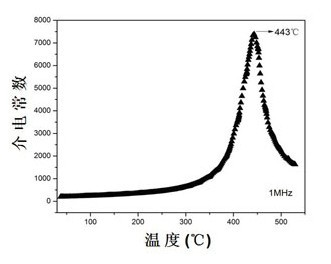

[0034] Place the green body on the sample stage, and use CO 2 The laser beam directly irradiates one side of the sample for 60s and the opposite side for 120s. During this process, the laser power is 1000W, and the defocus distance is 120 mm. Turn off the laser and let the sample cool down naturally. The prepared samples were annealed, processed, and tested. The available density value is 5.00 g / cm 3 (97.8% of the theoretical density value), Curie temperature Tc around 420°C, high-purity BaTi with a preferred orientation growth structure along the b-axis with a high degree of orientation 2 o 5 ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com