Frozen ceramic slurry 3D printing mechanism

A technology of 3D printing and ceramic slurry, which is applied in the direction of ceramic forming machines, manufacturing tools, additive processing, etc., can solve the problems of long drying and curing material layer and low processing efficiency, so as to improve processing efficiency, high processing efficiency, The effect of high specific strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

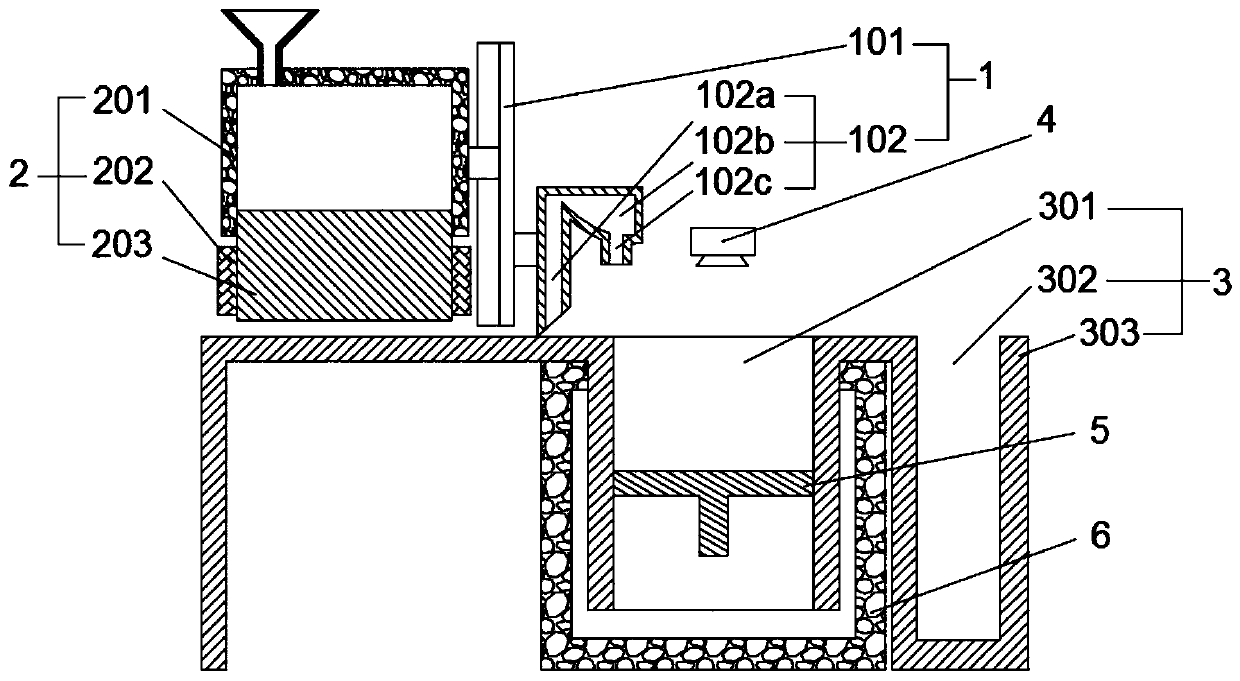

[0034] Embodiment 1, see Figure 1-3 , the present invention provides a technical solution: a frozen ceramic slurry 3D printing mechanism, including the following structure:

[0035] The scraping device 1 includes a horizontally moving slider 101 and a scraper 102. The scraper 102 is fastened to the right side of the horizontally moving slider 101 by screws. Contact and cooperate with the upper surface of the workbench 3, and drive the scraping device 1 to slide along the X direction through a stepping motor;

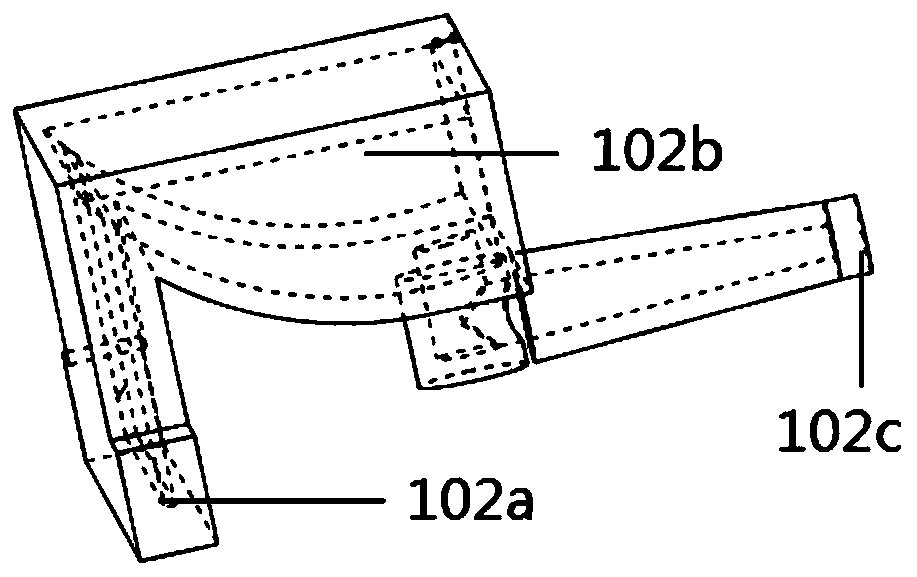

[0036] Scraper 102 comprises feed inlet 102c,, discharge outlet 102a, and feed inlet 102c is circular, and discharge outlet 102a is rectangle, and feed inlet and buffer bin 102b interface are circular and interface is positioned at buffer bin below, and feed outlet The interface 102b with the buffer bin is rectangular and the interface is located above the buffer bin;

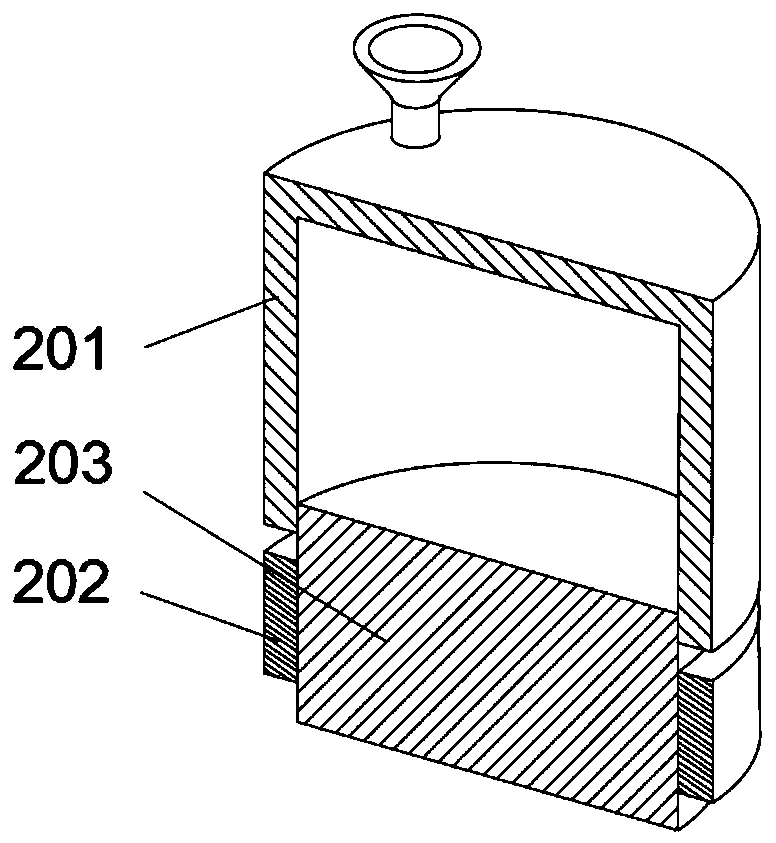

[0037] The freezing device 2 includes a freezing liquid box 201, a heater 202, and a pure copper fr...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that in operation 3, the laser scanning device 4 is turned on to irradiate the frozen material layer in selected areas, so as to realize the curing of the material layer;

[0049] Repeat operation 1 to operation 3 until the printing is completed, take out the workpiece and wash it in water to remove the frozen slurry and ceramic body in the unscanned area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com