Probiotic grain powder and production method and application thereof

A technology of probiotics and grain powder, which is applied in the field of food processing, can solve the problems of low nutrition adjustment efficiency and large loss of living strains, and achieve the effects of good digestion and absorption performance, more retention and high maturity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The making of embodiment 1 probiotic cereal powder

[0044] The process formula is as follows:

[0045] Main ingredients: 80 parts of black rice, 20 parts of black beans;

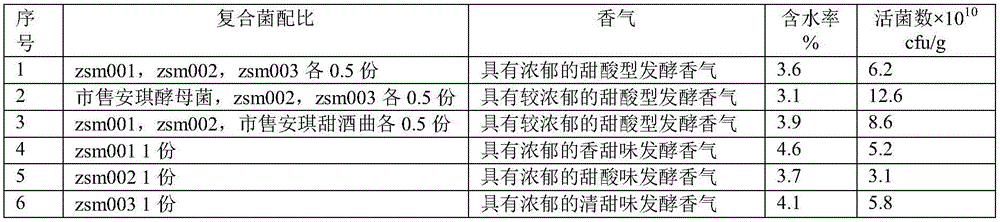

[0046] Excipient 1: The compound bacteria are 0.5 parts each of yeast, lactic acid bacteria and Rhizopus oryzae;

[0047] Excipient 2: 0.3 parts each of amylase, protease, cellulase and phytase;

[0048] Excipient 3: 10 parts of white sugar, 0.3 parts of amino acid, 5 parts of taurine, 6 parts of egg white protein powder;

[0049] Soaking solution: 120 parts of water, 0.8 parts of sodium glutamate;

[0050] Protective agent: 80 parts of water, 1 part of glycerin, 2 parts of trehalose, and 1 part of monoglyceride.

[0051] The production steps are as follows:

[0052] 1) The main material is soaked in soaking solution (temperature 35°C, time 5h), and material 1 is obtained;

[0053] 2) Refining material 1 (100% particle size passing 80 mesh, 90% passing 120 mesh) to obtain material 2;

[0054] ...

Embodiment 2

[0061] The influence of embodiment 2 soaking conditions on the quality of probiotic cereal flour

[0062] The main ingredients are 80 parts of barley and 20 parts of red beans. Except for the soaking conditions, the process formula of Example 1 is used.

[0063]It can be seen from Table 1 that after soaking at 35°C for 20 hours, the content of GABA is the highest, the number of viable probiotic bacteria is high, the moisture content is the lowest, and the product quality is the best. This is because suitable germination conditions are conducive to the transformation of GABA. Macromolecular substances such as starch, protein, and dietary fiber are degraded under the action of endogenous enzymes to produce small molecular sugars and free amino acids, which release bound minerals, which is beneficial The growth of microorganisms during the fermentation process reduces the water binding capacity, which is conducive to drying and dehydration. The product produced has a high number ...

Embodiment 3

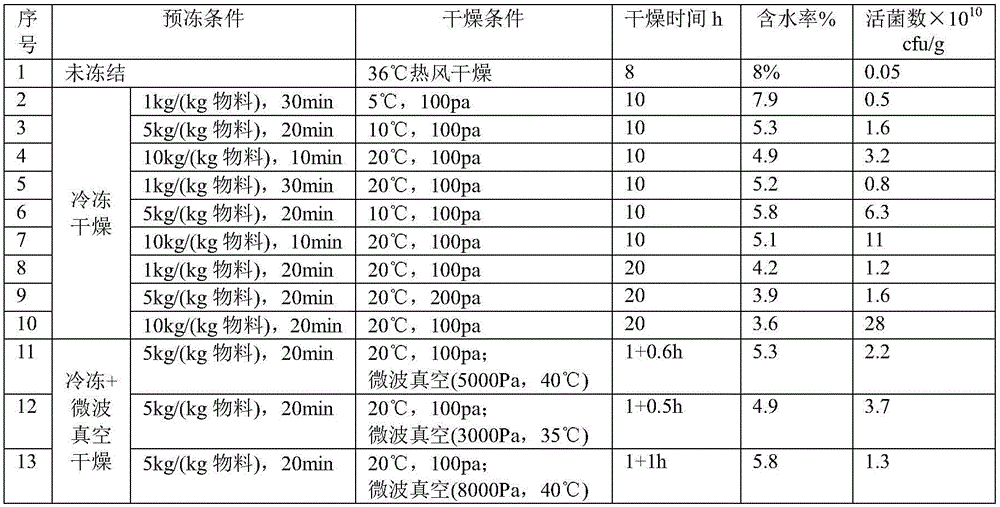

[0066] The influence of embodiment 3 pre-freezing and drying conditions on the probiotic rate of cereal probiotic powder, moisture content

[0067] The main ingredient is 100 parts of Job's tears. Except for the pre-freezing and drying conditions, the process formula of Example 1 is used. The effects of pre-freezing and drying conditions on the probiotics and moisture content in the probiotic grain powder are shown in Table 2. It can be seen from Table 2 that the number retention rate of viable bacteria is high when freeze-drying is used, and the retention rate of probiotics is small without freezing treatment.

[0068] Table 2 Effects of prefreezing and drying conditions on probiotics and moisture content in probiotics cereal powder

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com