Continuous vacuum quick freezing device and continuous vacuum quick freezing method for foods

A freezing equipment and fast vacuum technology, applied in the fields of food freezing, food preservation, food science, etc., can solve the problems of difficulty in ensuring food freezing speed requirements and uniformity, low cooling capacity utilization efficiency, large power configuration, etc. Cost and operating energy consumption, accelerated freezing speed, excellent effect of vaporization and heat absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

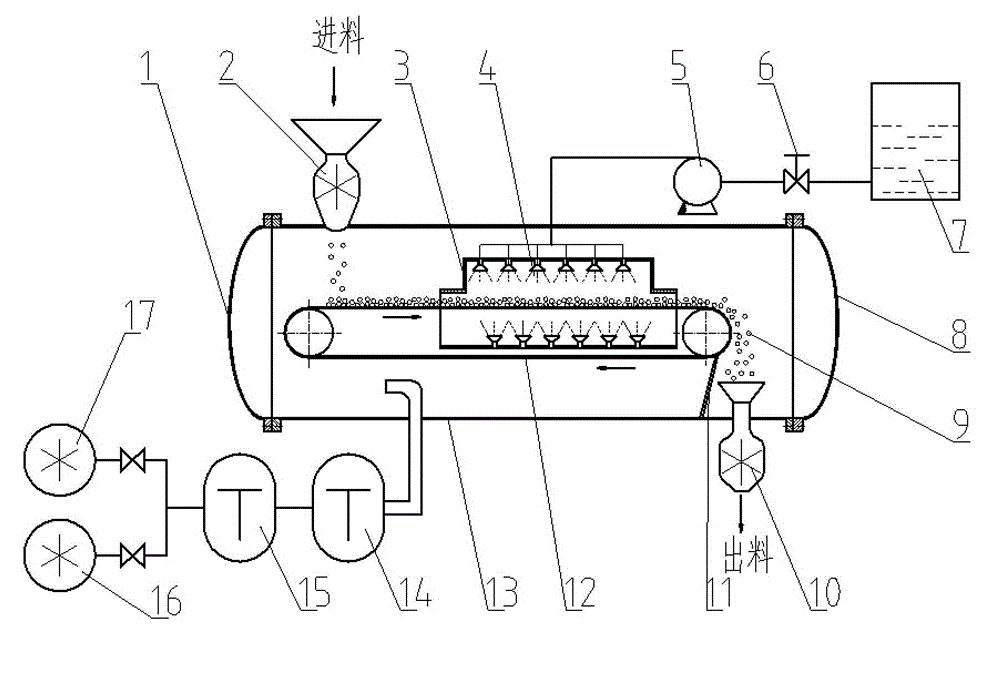

[0022] The continuous food vacuum quick freezing equipment of the present embodiment is as figure 2 As shown, it includes a sealed vacuum chamber body 13 communicated with vacuum generating equipment. The vacuum chamber body 13 is composed of a cylindrical body in the middle and front and rear chamber doors 1, 8 sealed at both ends. The vacuum generating equipment is composed of two water ring pumps 16, 17 in parallel and two Roots pumps 14, 15 in series. The parallel water ring pump is used as the backing pump of the series Roots pump, so that the pumping capacity of the vacuum unit is high and can be The water vapor in the vacuum chamber is extracted in time to ensure the vacuum degree required for the vaporization of water at low temperature.

[0023] The top of one end of the vacuum chamber body 13 has a bucket-shaped feed opening equipped with a feed locker 2 (also known as a star unloader), and the bottom of the other end has a discharge port equipped with a discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com