Method for freezing prawns by adopting ultrasonic and high hydrostatic pressure

A high static pressure, ultrasonic technology, applied in the direction of freezing/cooling preservation of meat/fish, etc., can solve the problems of destroying the freshness of fresh prawns, reducing water holding capacity, slow freezing rate, etc., to avoid denaturation and freezing of cooked proteins Improve the speed and prevent the effect of easy blackening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

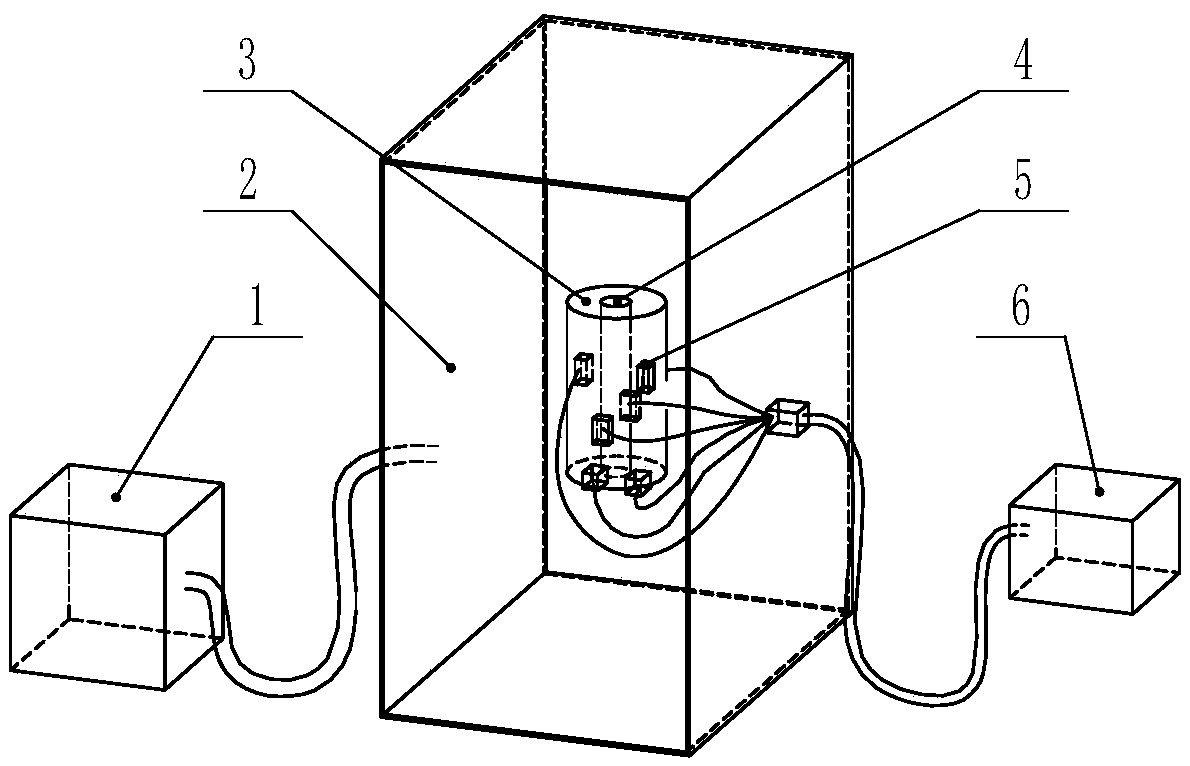

[0048] figure 1 It is a schematic diagram of the ultrasound combined with high static pressure freezing device used in this embodiment. like figure 1 As shown, it includes a refrigerant cycle machine 1, a high static pressure device 2, a plurality of acoustic wave transducers 5, an ultrasonic control box 6 and a high static pressure sample container; the high static pressure sample container includes an outer cavity 3 and an inner cavity 4, and multiple Ultrasonic transducers 5 are evenly distributed between the inner cavity 4 and the outer cavity 3, and a K-type thermocouple is arranged at the bottom of the high static pressure sample container for measuring the temperature of the inner cavity. Multiple ultrasonic transducers 5 are connected to the ultrasonic control box 6 , the refrigerant cycler 1 is connected to the high static pressure device 2 , and the high static pressure sample container is placed inside the high static pressure device 2 .

[0049] The method of obt...

Embodiment 2

[0052] The method of obtaining high-quality new-type frozen prawns by the ultrasound in cooperation with the high static pressure freezing treatment of the present embodiment comprises the following steps:

[0053] Select prawns (13-15g / piece, length 10-13cm) as the experimental raw material, put 1Kg of prawns in a 2Kg mixture of ice and water, let them die for 20 minutes, dry the surface moisture at room temperature, and use 15*22cm aluminum foil Packing bag, vacuum packing under 0.08MPa, 6 pcs per bag. 1 hour before the start of the experiment, the refrigerant circulation equipment was turned on, and the temperature was lowered to -18~-20°C. At the same time, a certain amount of 30% ethanol-water (V:V) solution was injected into the high static pressure sample container; 5 bags of sealed prawns were placed Put it into the high static pressure sample container, put the third prawn in a bag in the middle of the pressure chamber with a K-type thermocouple, and ensure that the r...

Embodiment 3

[0055] The method of obtaining high-quality new-type frozen prawns by the ultrasound in cooperation with the high static pressure freezing treatment of the present embodiment comprises the following steps:

[0056] Select vannamei shrimp (11-13g / piece, length 8-11cm) as the experimental raw material, put 1Kg of prawns in a 2Kg mixture of ice and water, let them die for 20 minutes, dry the surface moisture at room temperature, and pack them in 15*22cm aluminum foil Bags, vacuum packed under 0.1MPa, 8 pcs per bag. Turn on the refrigerant circulation equipment 1 hour before the start of the experiment, lower the temperature to -18~-20°C, and inject a certain amount of 40% ethanol-water (V:V) solution into the high static pressure sample container at the same time; put 5 bags of sealed prawns into Put it into the high static pressure sample container, put the third prawn in a bag in the middle of the pressure cavity with a K-type thermocouple, and the liquid level of the refrigera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com